Rock shearing-seepage testing machine and testing method thereof

A testing machine and rock sample technology, applied in the field of rock mechanics, can solve problems such as inability to simulate, leaking water due to poor sealing, and unsealed rock samples, so as to achieve the effect of convenient installation and operation and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

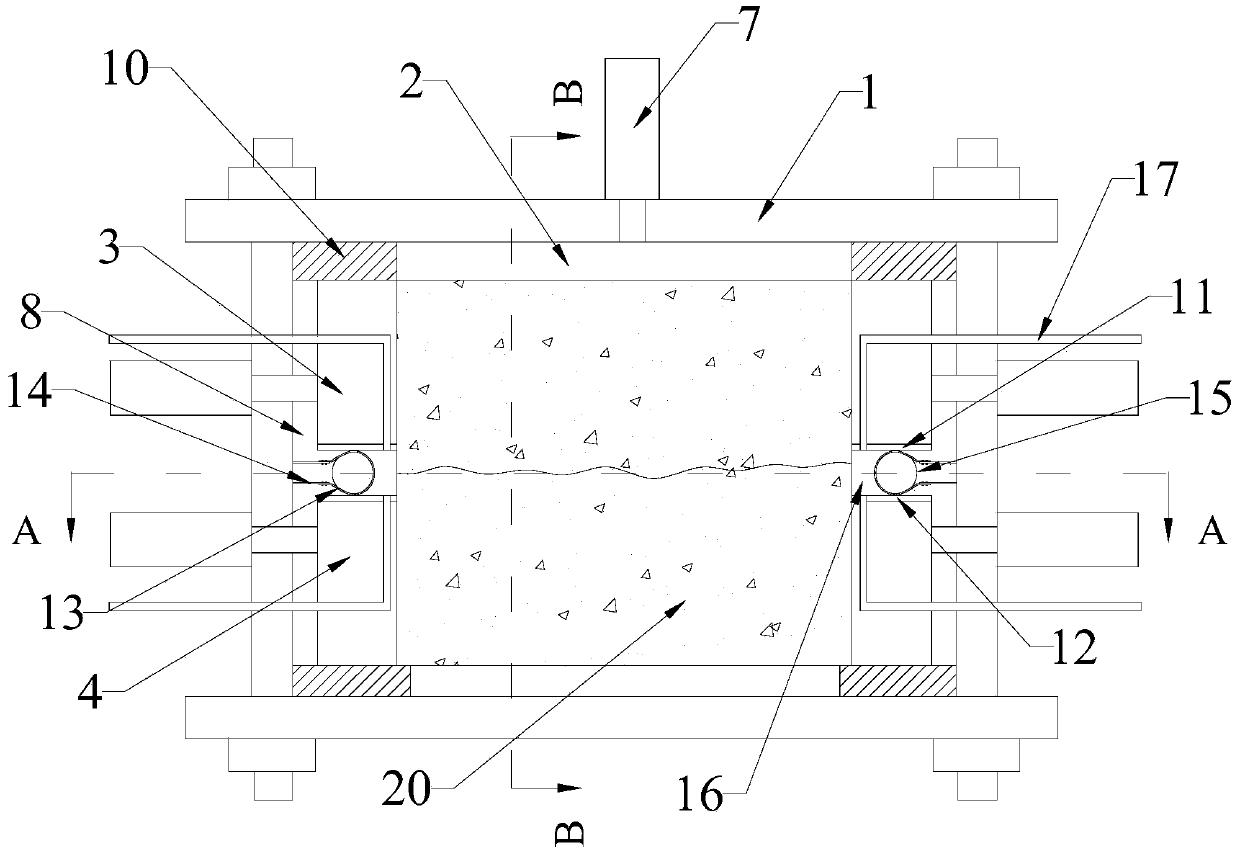

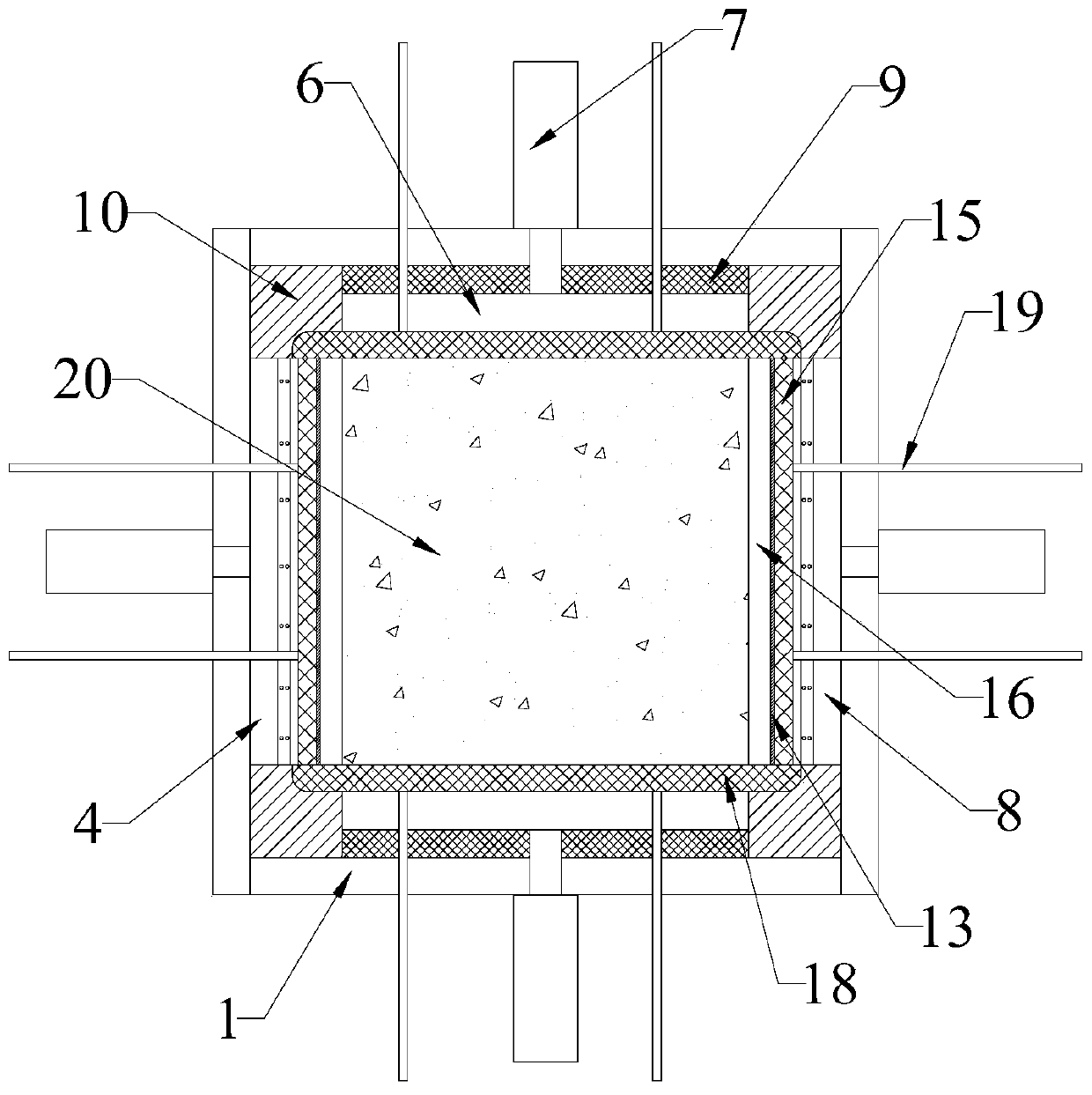

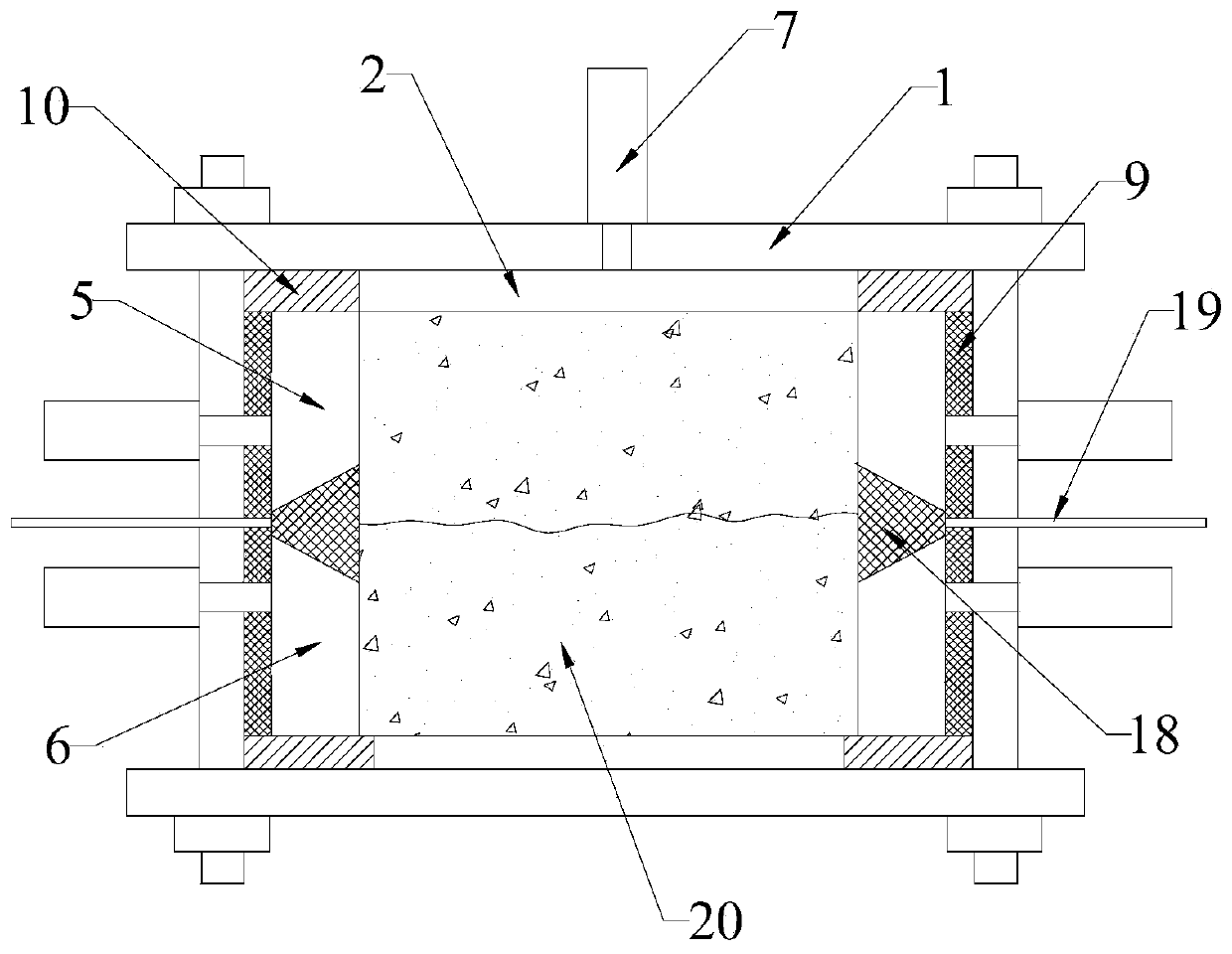

[0029] Such as Figure 1-3 As shown, the rock shear-seepage testing machine includes a sealing test box, and the sealing test box includes a hollow frame composed of six outer plates 1, and the six outer plates 1 are respectively a bottom plate, four side plates and an upper plate, 4 side wall siege boxes, the lower end is fixedly connected with the bottom plate, and the upper end is fixedly connected with the upper end, the rock sample 20 is installed in the hollow frame, and a backing plate is placed between the lower end of the rock sample 20 and the bottom plate, and the rock sample The upper end of the 20 is provided with a Z-axis loading plate 2, both sides of the rock sample 20 in the X-axis direction are provided with an upper X-axis loading plate 3 and a lower X-axis loading plate 4, and both sides of the rock sample 20 in the Y-axis direction are provided with an upper Y axis. Axis loading plate 5 and lower Y-axis loading plate 6, Z-axis loading plate 2, upper X-axis...

Embodiment 2

[0034] The test method of the rock shear-seepage testing machine described in embodiment one may further comprise the steps:

[0035] (1) The rock sample 20 is placed in the hollow frame, and the first polyurethane water sealing bag 15 and the second polyurethane water sealing bag 18 are filled with hydraulic oil through the hydraulic system to make it reach the set pressure. The water sealing bag 15 is used to support the elastic metal sleeve 13, so that its upper and lower ends are respectively sealed against the upper sealing sheet 11 and the lower sealing sheet 12, so as to realize the sealing of the water seepage chamber 16, and the second polyurethane water sealing bag 18 realizes sealing against the water seepage. Cavity 16 and both sides of rock sample 20 cracks are sealed;

[0036] (2) Load the set pressure on the Z-axis loading plate 2, the lower X-axis loading plate 4, the upper Y-axis loading plate 5, and the lower Y-axis loading plate 6 through the stress loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com