A Method for Determination of Viscosity Characteristics of Oil-Water Emulsion System Considering Phase Separation Behavior

A technology of oil-water emulsification and determination method, which is applied in flow characteristics, analysis materials, material excitation analysis, etc., and can solve problems such as retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

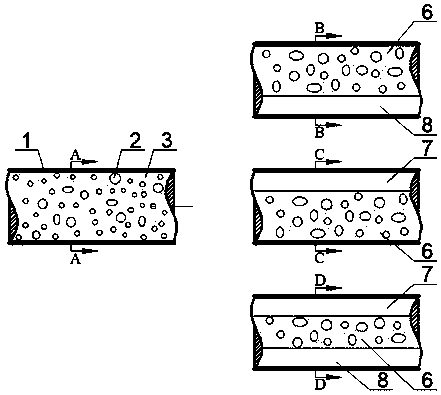

[0076] Below in conjunction with accompanying drawing, the present invention will be further described:

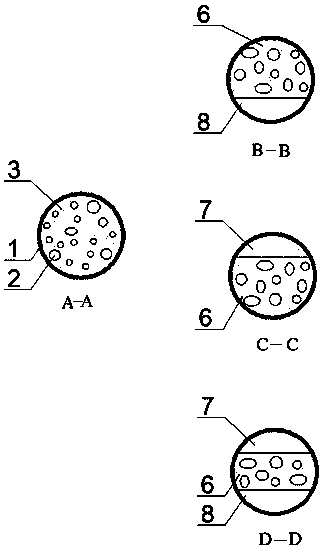

[0077] Such as figure 1 As shown, in the oil-water mixed pipeline 1, the dispersed phase water phase 2 is dispersed in the continuous phase oil phase 3 to form the original water-in-oil (W / O) emulsification system. In , due to the occurrence of phase separation behavior, the formation of figure 2 Three possible stratification forms are shown: free oil phase 7 and homogeneous emulsion phase 6, homogeneous emulsion phase 6 and free water phase 8, and free oil phase 7, homogeneous emulsion phase 6 and free water phase 8.

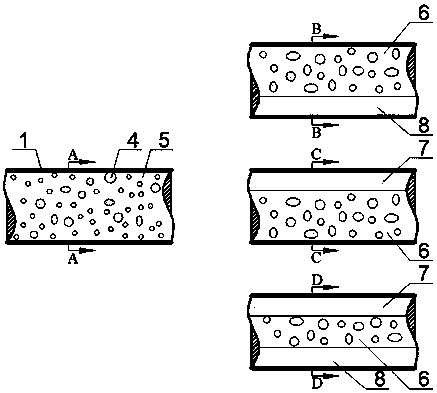

[0078] Similarly, if image 3 As shown, in the oil-water mixed pipeline 1, the dispersed phase oil phase 4 is dispersed in the continuous phase water phase 5 to form the original oil-in-water (O / W) emulsification system. In , due to the occurrence of phase separation behavior, the formation of Figure 4 Three possible stratification forms are shown: fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com