Novel dielectric filter coupling structure

A dielectric filter and coupling structure technology, which is applied in the field of communication, can solve the problems of complex capacitive coupling structure and difficult process realization, and achieve the effect of small negative coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

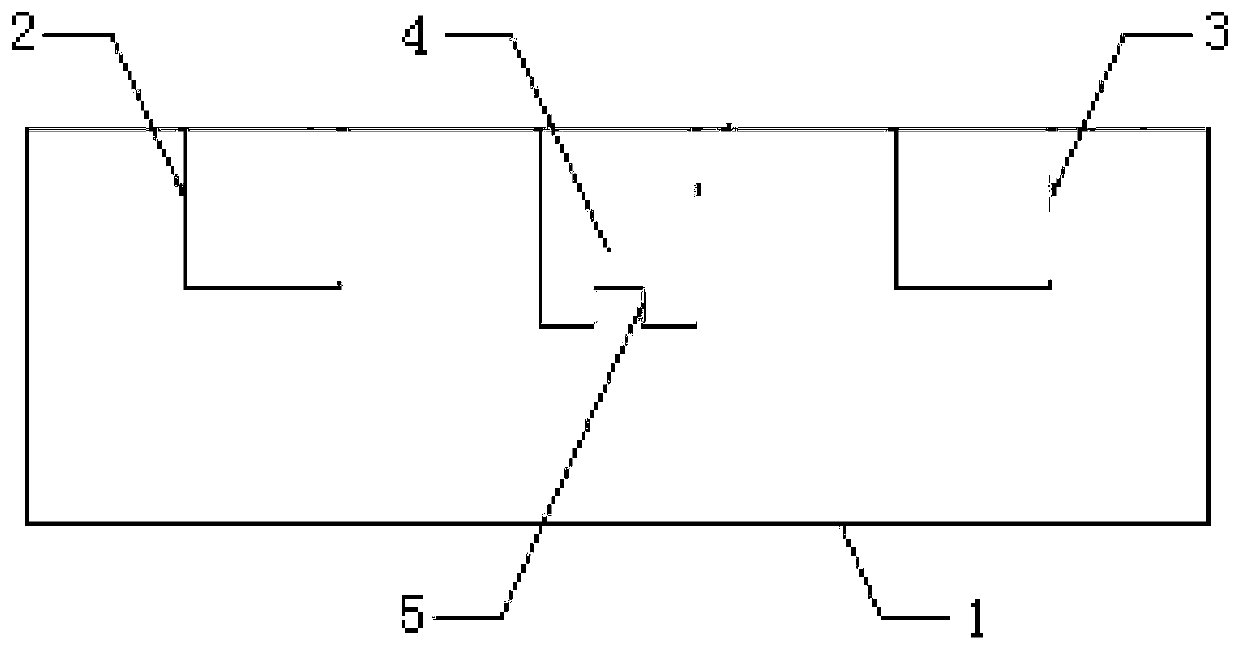

Embodiment 1

[0018] Embodiment 1: A new type of dielectric filter coupling structure, including a dielectric filter body 1, a first blind hole 2 and a second blind hole 3, the first blind hole 2 and the second blind hole 3 are arranged in the dielectric filter On the same side of the filter body 1, the first blind hole 2 and the second blind hole 3 form two dielectric resonators with the medium on the dielectric filter body 1, and a negative coupling hole is arranged between the two dielectric resonators 4. The openings of the negative coupling hole 4 and the first debugging hole 2 and the second debugging hole 3 are located on the same surface of the dielectric filter body 1. One end of the negative coupling hole 4 runs through the dielectric filter body 1, and the other end is a closed end , the negative coupling hole 4 is provided with a boss 5, the boss 5 is integrated with the dielectric filter body 1, and the inner wall of the negative coupling hole 4 and the outer wall of the boss 5 ...

Embodiment 2

[0023] Embodiment 2: A new type of dielectric filter coupling structure, including a dielectric filter body 1, a first blind hole 2 and a second blind hole 3, the first blind hole 2 and the second blind hole 3 are arranged in the dielectric filter On the same side of the filter body 1, the first blind hole 2 and the second blind hole 3 form two dielectric resonators with the medium on the dielectric filter body 1, and a negative coupling hole is arranged between the two dielectric resonators 4. The openings of the negative coupling hole 4 and the first debugging hole 2 and the second debugging hole 3 are located on the same surface of the dielectric filter body 1. One end of the negative coupling hole 4 runs through the dielectric filter body 1, and the other end is a closed end , the negative coupling hole 4 is provided with a boss 5, the boss 5 is integrated with the dielectric filter body 1, and the inner wall of the negative coupling hole 4 and the outer wall of the boss 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com