Top drive load measurement weight on bit

A hook load, drilling rig technology, applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve problems such as accuracy limitations, achieve high accuracy, overcome shortcomings and problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

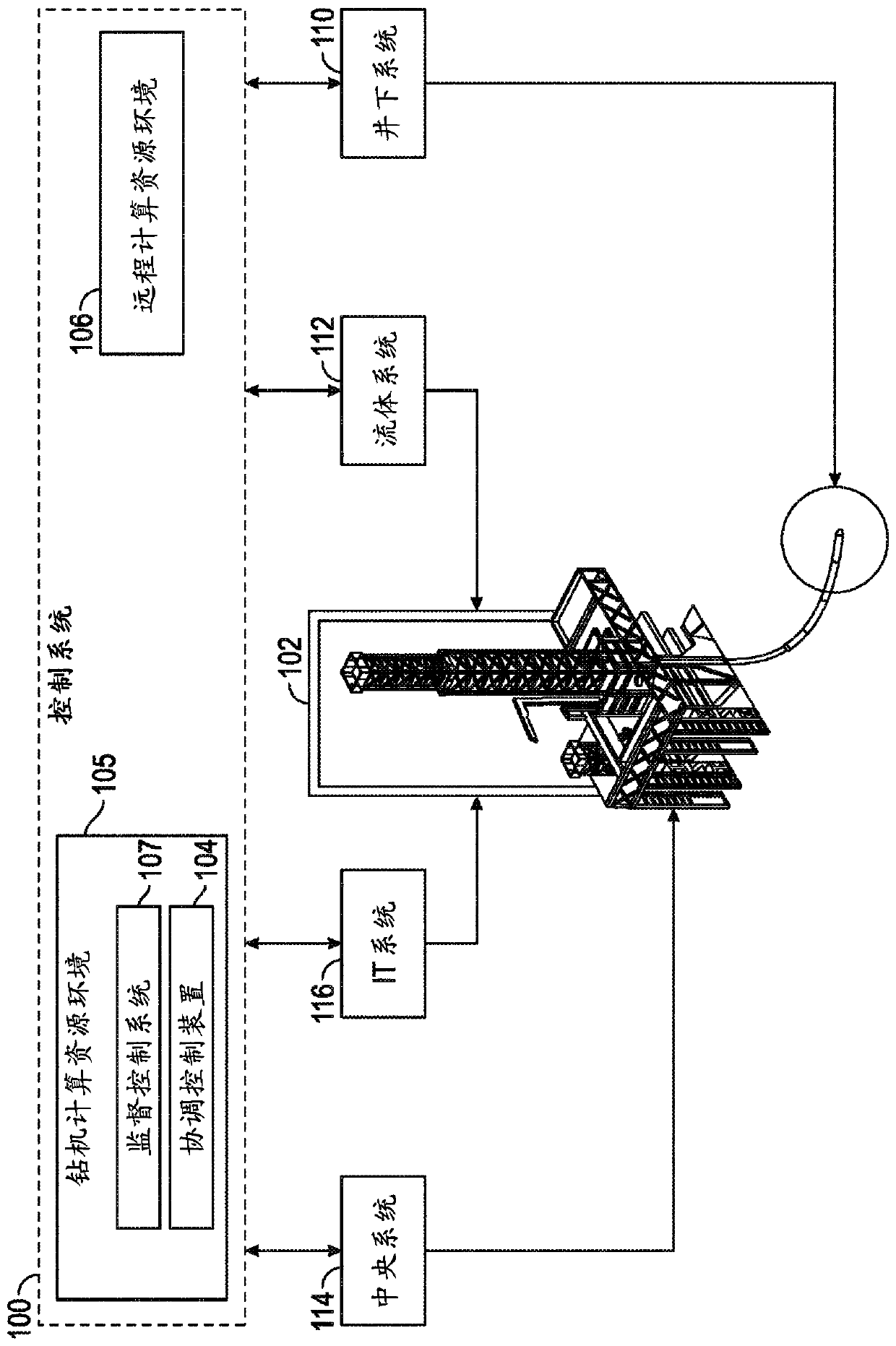

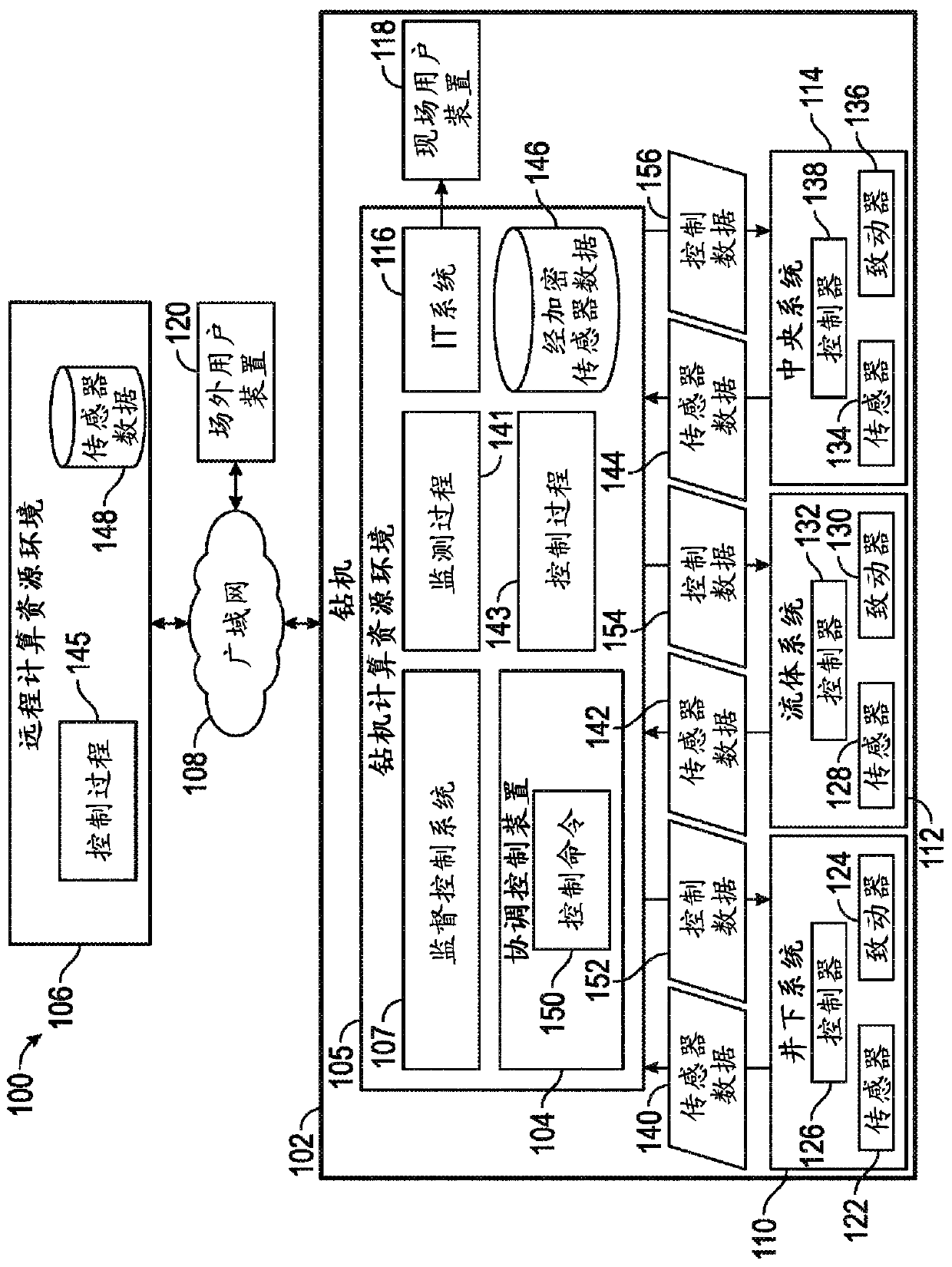

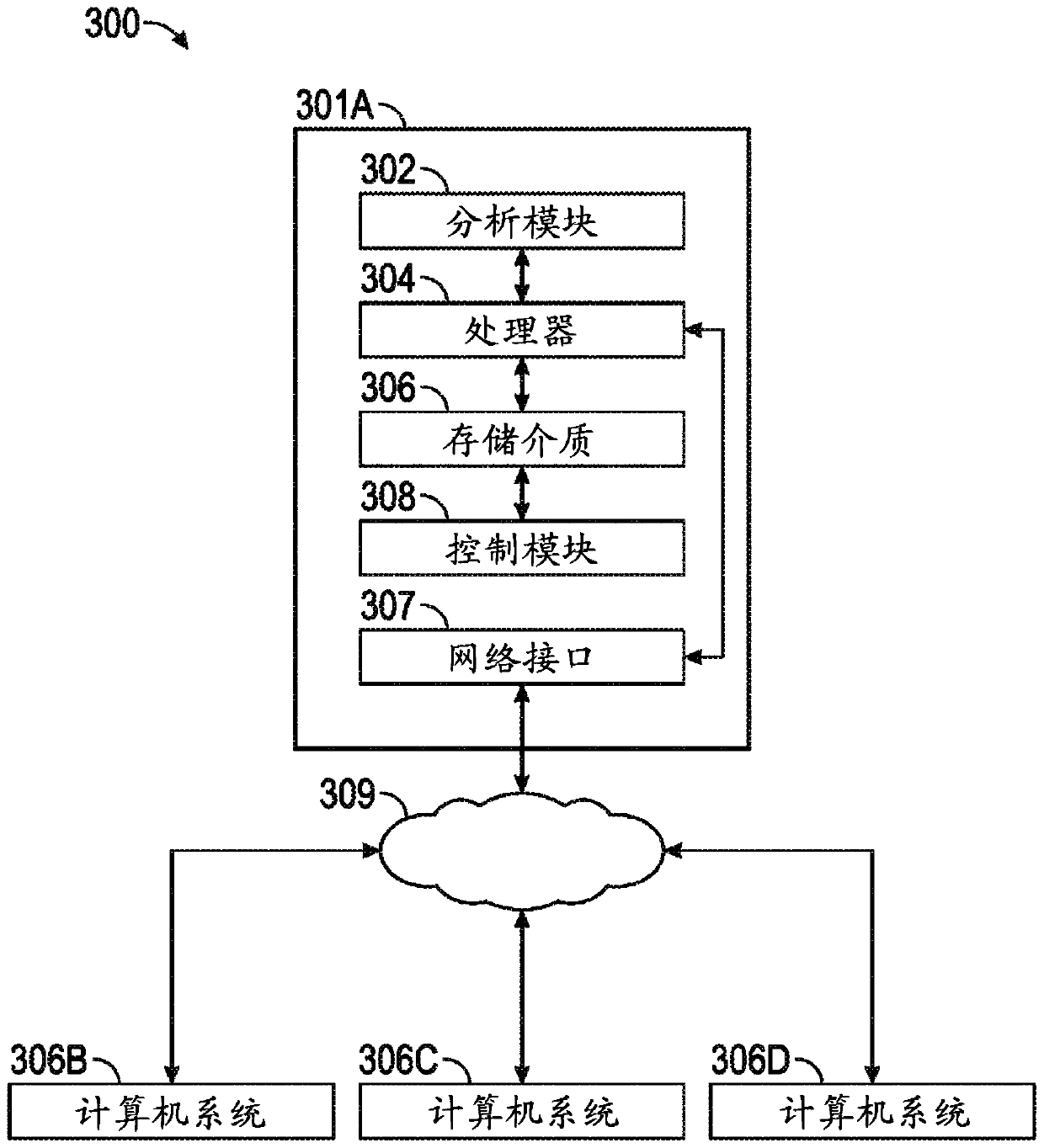

[0026] Given the general discussion below, by referring to the following Figure 1 to Figure 7B The preferred embodiments can be better understood. The present disclosure may be more readily understood in the context of a high-level description of certain embodiments.

[0027] Embodiments of the present invention provide a top drive with a higher accuracy load measurement system in which the strain gauges can be built into the vertical tie rods used to suspend the top drive from the traveling block. This solution allows built-in strain gauges to monitor only tensile stress (and not shear), where tensile stress measurement can be performed with very high accuracy.

[0028] A tie rod with a built-in weight-on-bit sensor was tested. The purpose of the test was to verify that the tie rods with built-in strain gauges (WOB sensors) provided 99.5% load measurement accuracy over the entire range and 99.7% load measurement accuracy from 5% to 50%. The test was performed on a set of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com