Cigar wrapper tobacco leaf and cigar filler tobacco leaf co-plant production type cigar tobacco cultivation method

A cultivation method and tobacco leaf technology, applied in tobacco cultivation, etc., can solve the problems of difficulty in producing high-quality cigar wrapper tobacco leaves and filler tobacco leaves at the same time, waste, etc., achieve outstanding smoking style characteristics, reduce raw material costs, and improve production benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

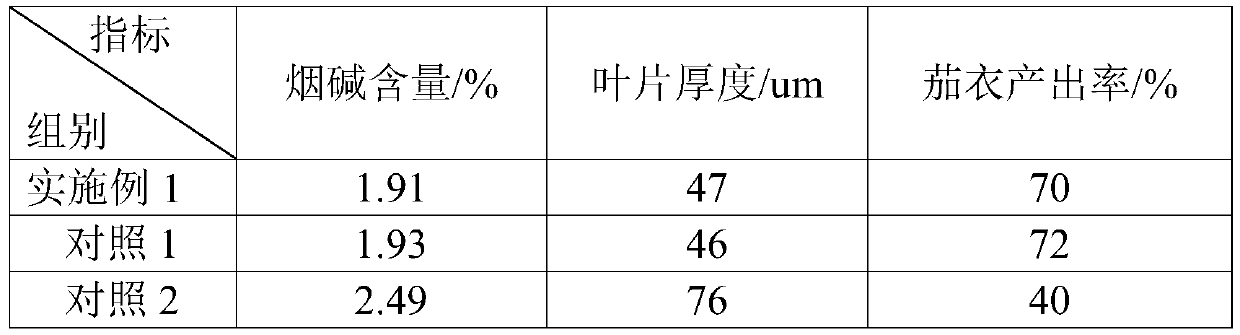

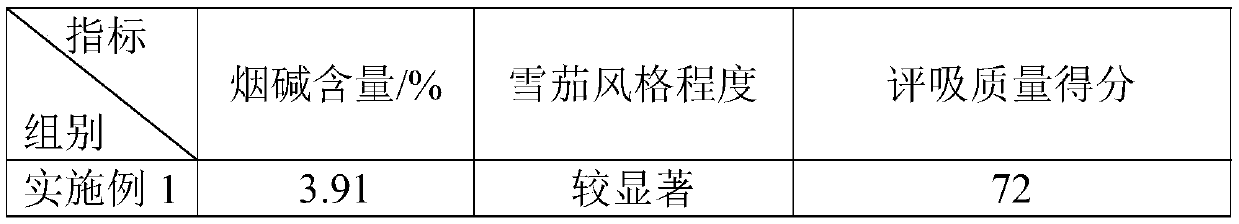

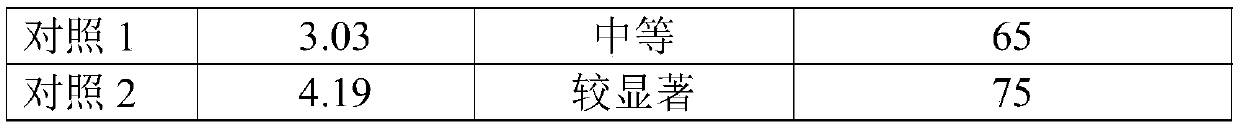

Examples

Embodiment 1

[0025] The first step is to build a shade shed in the field, the bamboo and wood structure of the shed, a white net, a height of 3m, and shade around;

[0026] The second step is to select the excellent cigar variety Chuanxue No. 2 (selected from the middle line of the Cuban variety havana92), and apply 180kg / hm of pure nitrogen 2 (The amount of fertilizer used for filler production is 150kg / hm 2 , wrapper production is 240kg / hm 2 ), the ratio of nitrogen, phosphorus and potassium is 1:0.5:1. The seedling raising method is floating seedling raising, the transplanting method is cellar transplanting, and the row spacing is 90cm×50cm;

[0027] The third step is to start harvesting when the dark green of the lower leaves fades 45 days after transplanting. Harvest 3 to 4 pieces each time, and dry them according to the cigar wrapper leaf airing technology. The tobacco plants will bud 50 days after planting. But it cannot remove the top flower of the tobacco plant;

[0028] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com