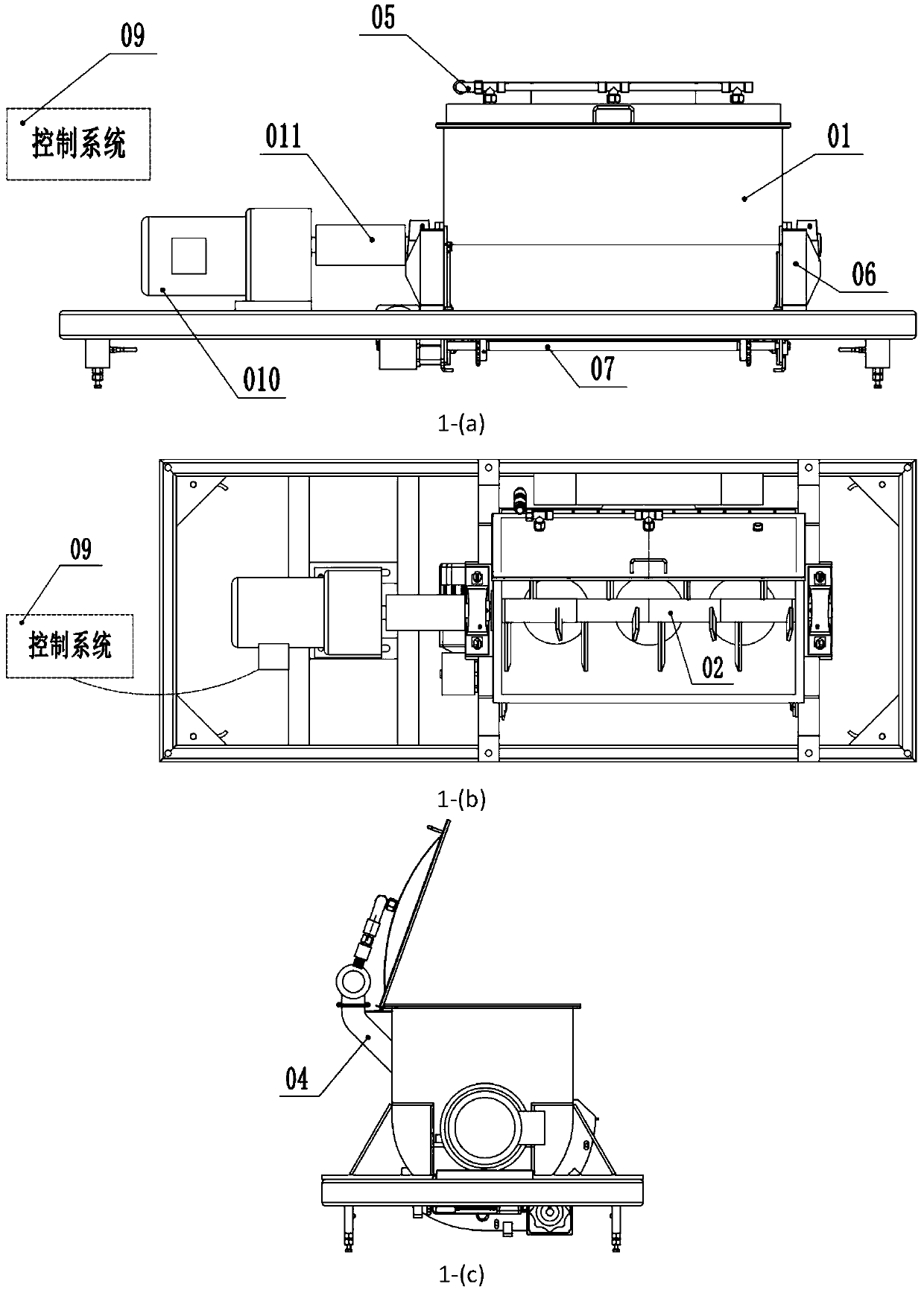

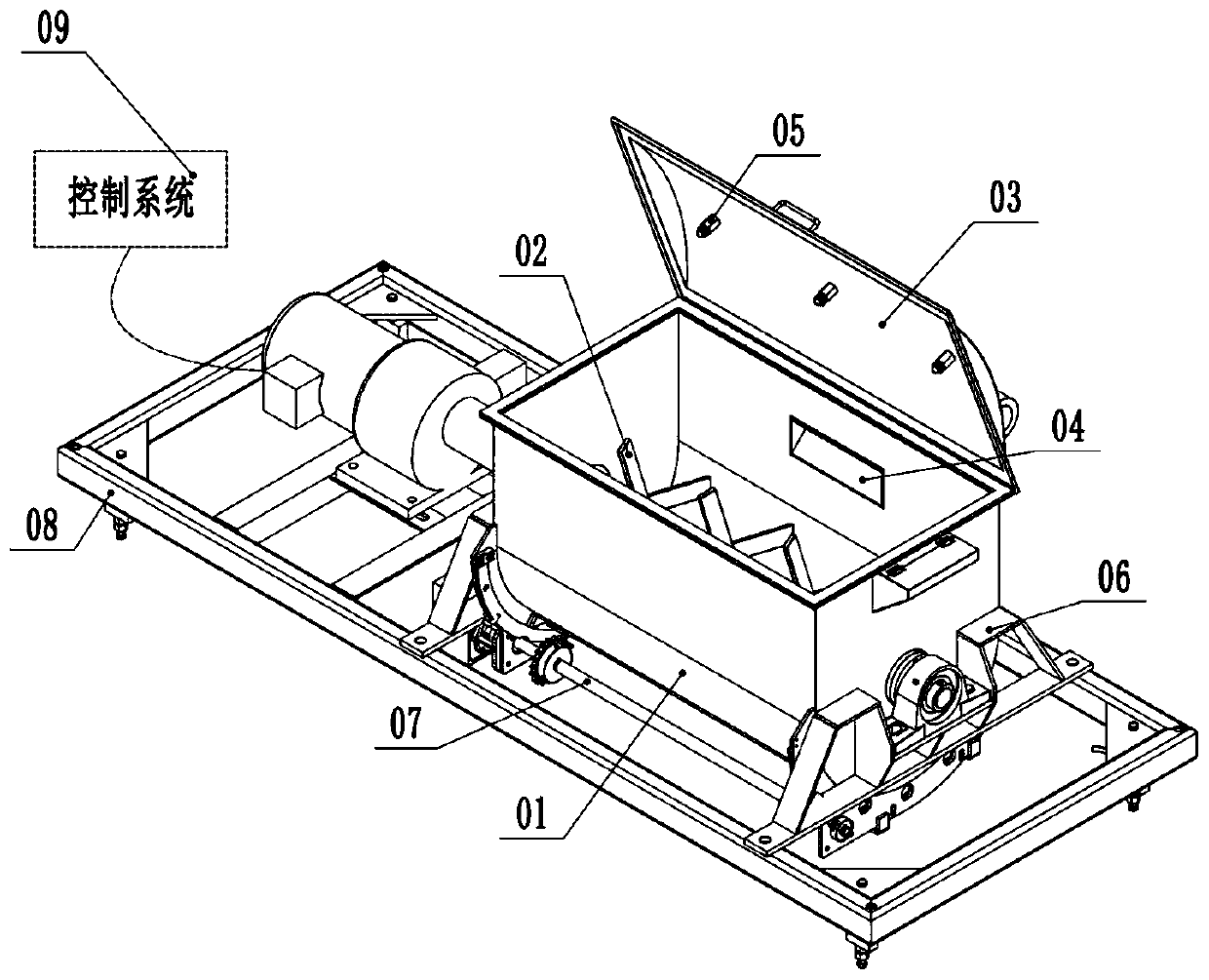

Automatic flour mixer system

A mixer and flour technology, applied in the directions of dough mixers, horizontal installation tools mixing/kneading, structural components of mixing/kneading machines, etc. Accurate control and other issues, to achieve the effect of compact structure, simple operation, saving material and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

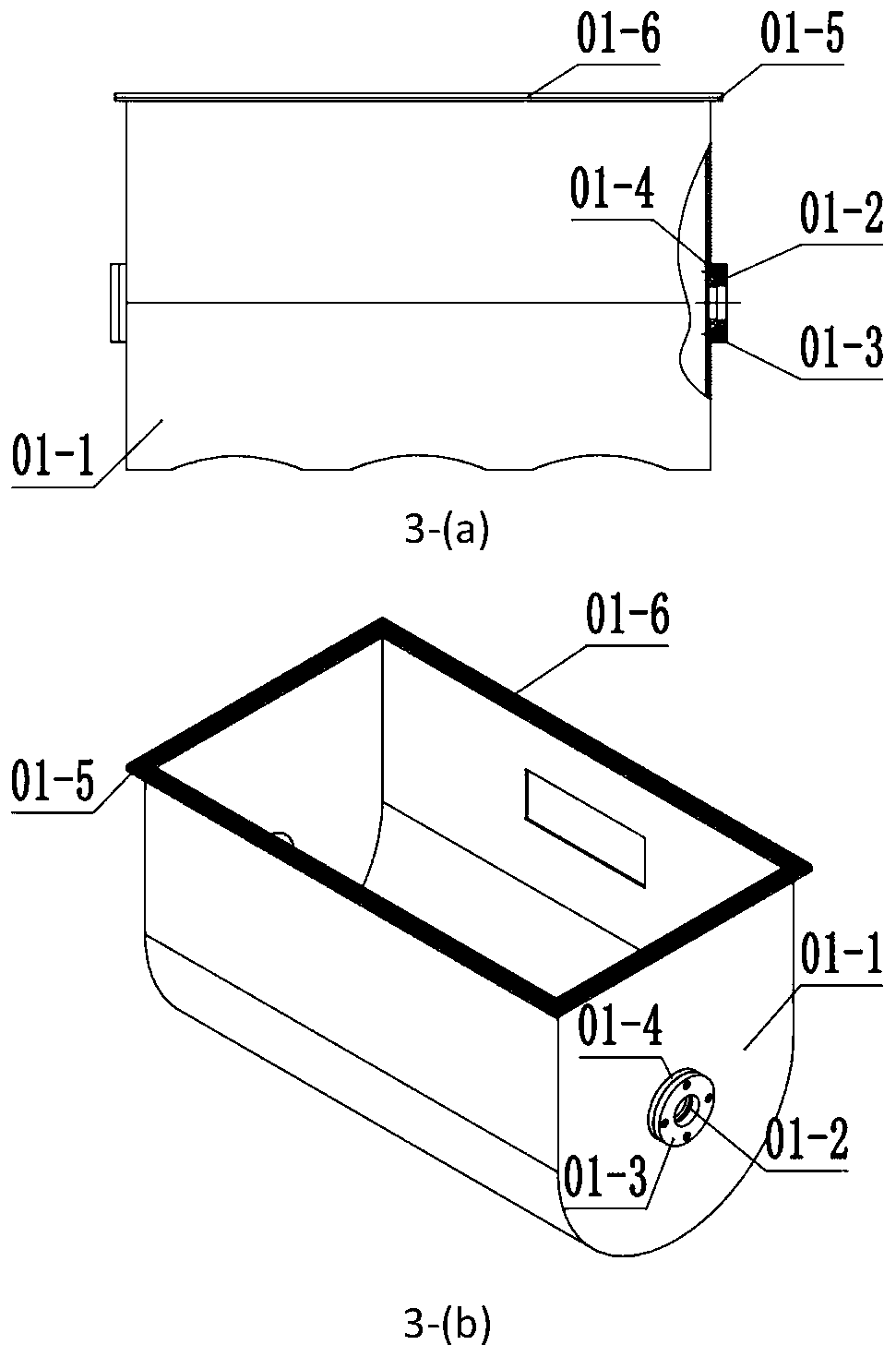

[0037] The specific implementation of the present invention is as follows: in an automatic flour mixer system, the socket 04-1 in the material inlet assembly 04 is connected to the plug joint in the flexible powder feeding device, and the clean water inlet in the flow control assembly 05 It is connected with the clean water delivery pipe to prepare for the stirring work of the agitator system; in the control system 09, set the input amount of flour to be stirred, the ratio of clean water to flour, and the mixing time and other predetermined parameters, and the middle warehouse of the warehouse door assembly 07 The door 07-9 is in the closed state, start the agitator system, the flour enters the barrel assembly 01 through the flexible powder feeding device through the feeding port assembly 04, and at the same time, the clean water passes through the flow control assembly 05 through the nozzle 05- 2 Spray into the cylinder assembly 01, the drive motor 010 drives the stirring shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com