Double-layer composite mold and mounting method

A double-layer, mold technology, applied in the direction of mold fixtures, mold auxiliary parts, manufacturing tools, etc., can solve the problems of low reuse rate and inflexible rib spacing, so as to improve versatility, flexibility, and sealing gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

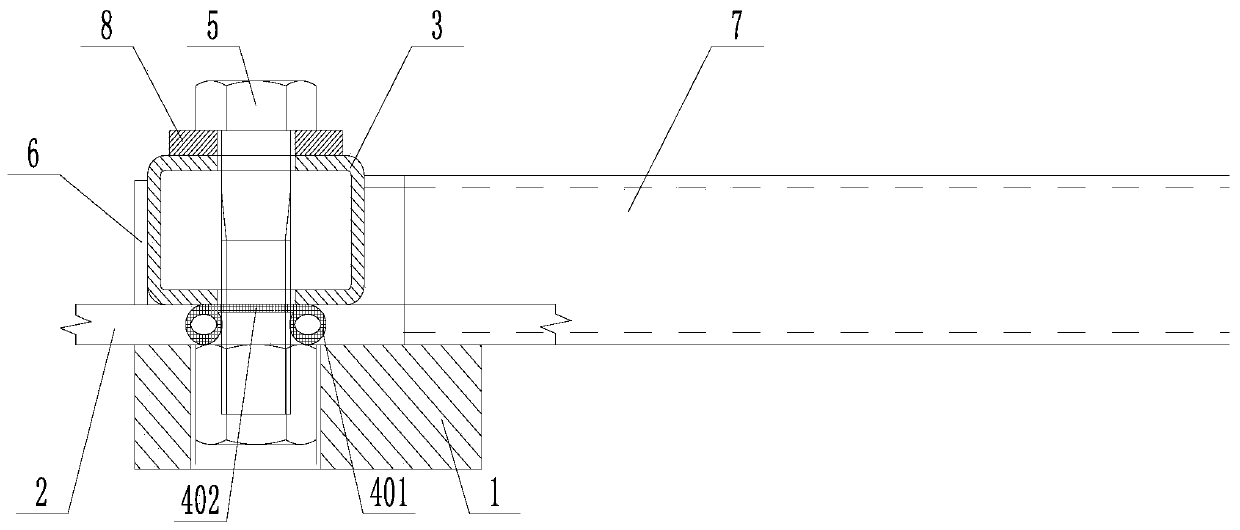

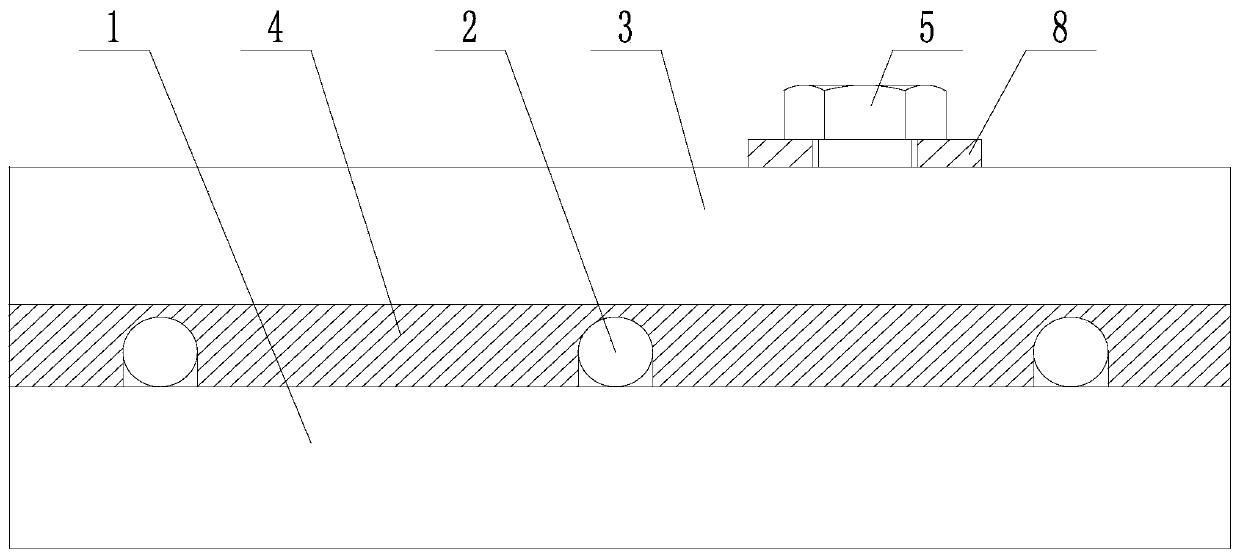

[0032] Such as Figure 2 to Figure 4 A double-layer laminated mold is shown, including a bottom plate 1, a steel bar 2 passing through the pouring area, and a connecting piece 3 above the bottom plate 1, and the steel bar 2 is located between the bottom plate 1 and the connecting piece 3 A seal 4 is also provided between the bottom plate 1 and the connecting piece 3 , and the bottom plate 1 and the connecting piece 3 are fixedly connected by bolts 5 .

[0033] In this embodiment, a connecting piece 3 is arranged above the bottom plate 1, and the steel bar 2 passes between the two, and the effect of clamping the steel bar 2 is realized by utilizing the gravity of the connecting piece 3 and the fastening of the bolts. A sealing member 4 is also arranged between the bottom plate 1 and the connecting member 3 to seal the gap and prevent the slurry from running and leaking. In this embodiment, the spacing of the reinforcing bars 2 is no longer a constraint of the pouring structure...

Embodiment 2

[0037] Such as Figure 2 to Figure 4 In the shown double-layer laminated mold, on the basis of Example 1, the bottom plate 1 is rectangular, and the connector 3 is a rectangular tube, and the long axis of the rectangular tube is parallel to the long axis of the bottom plate 1 ; The width of the bottom plate 1 is greater than the width of the rectangular tube. The profiled steel plate 6 is welded on the forming surface of the rectangular tube. The side surface of the checkered steel plate 6 facing the pouring area is coplanar with the side surface of the bottom plate 1 facing the pouring area. Said sealing element 4 is laid between the base plate 1 and the connecting element 3 and encloses the reinforcement 2 from above. The sealing member 4 is an EPDM rubber strip; the sealing member 4 includes two hollow tube parts 401 , and the tops of the two hollow tube parts 401 are fixedly connected by a rubber part 402 . The bottom plate 1 is a steel plate. It also includes a pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com