Multi-layer weft-knitted spacer fabric for fire-fighting heat-insulating clothes

A technology of spacer fabric and heat insulation layer, which is applied in the textile field, can solve the problems affecting the work efficiency and comfort of firefighters, achieve excellent protection performance, improve comfort, and reduce the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

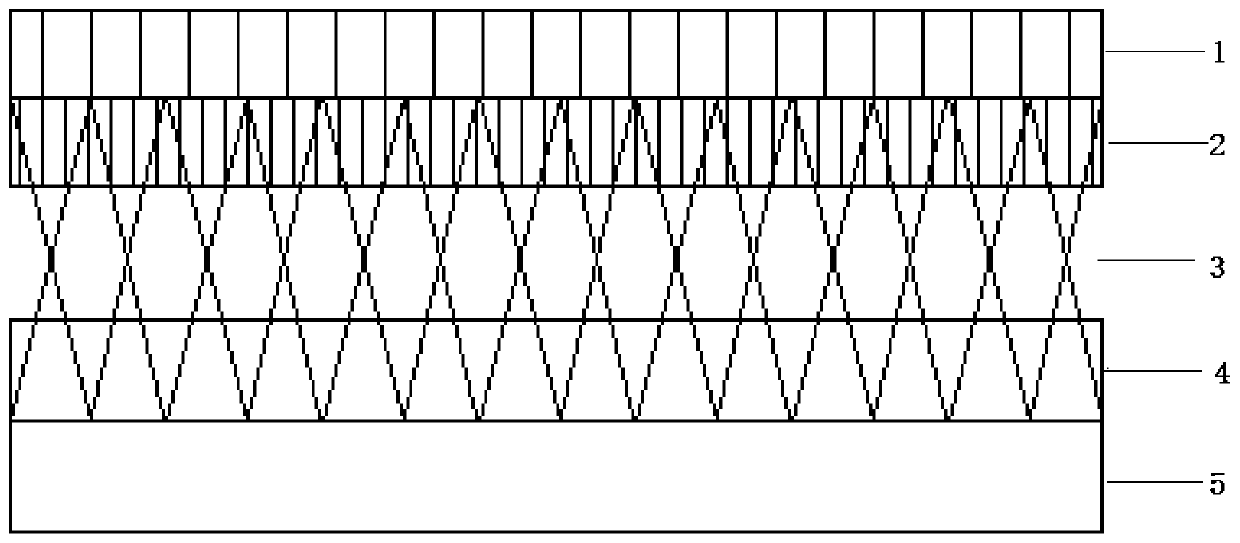

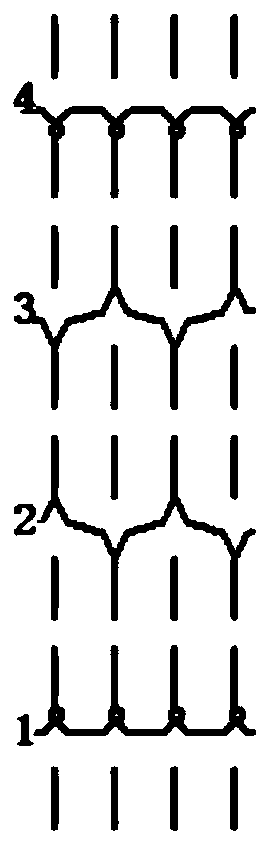

[0013] This embodiment discloses a multi-layer weft-knitted spacer fabric used for fire-fighting and heat-insulating clothing, which includes at least six layers of structure, the outermost layer is a heat radiation layer, and the microporous aluminum foil formed by laser drilling can play a role in radiation protection. , Waterproof, has good air permeability and high temperature resistance. The rest of the five-layer structure is directly divided into 4-way one-time weaving by the double-sided circular knitting machine (such as figure 1 and figure 2 As shown), no post-sewing is required, which reduces the complexity of the traditional manufacturing process. The one-time molded five-layer structure includes reflective film attachment layer 5, flame-retardant and heat-insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com