Latex electrodeposition device

An electrodeposition device and latex technology, applied in the field of rubber processing, can solve the problems of large corrosion of equipment, increased solid colloids, long acid solidification time, etc., and achieve the effect of leveling the liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

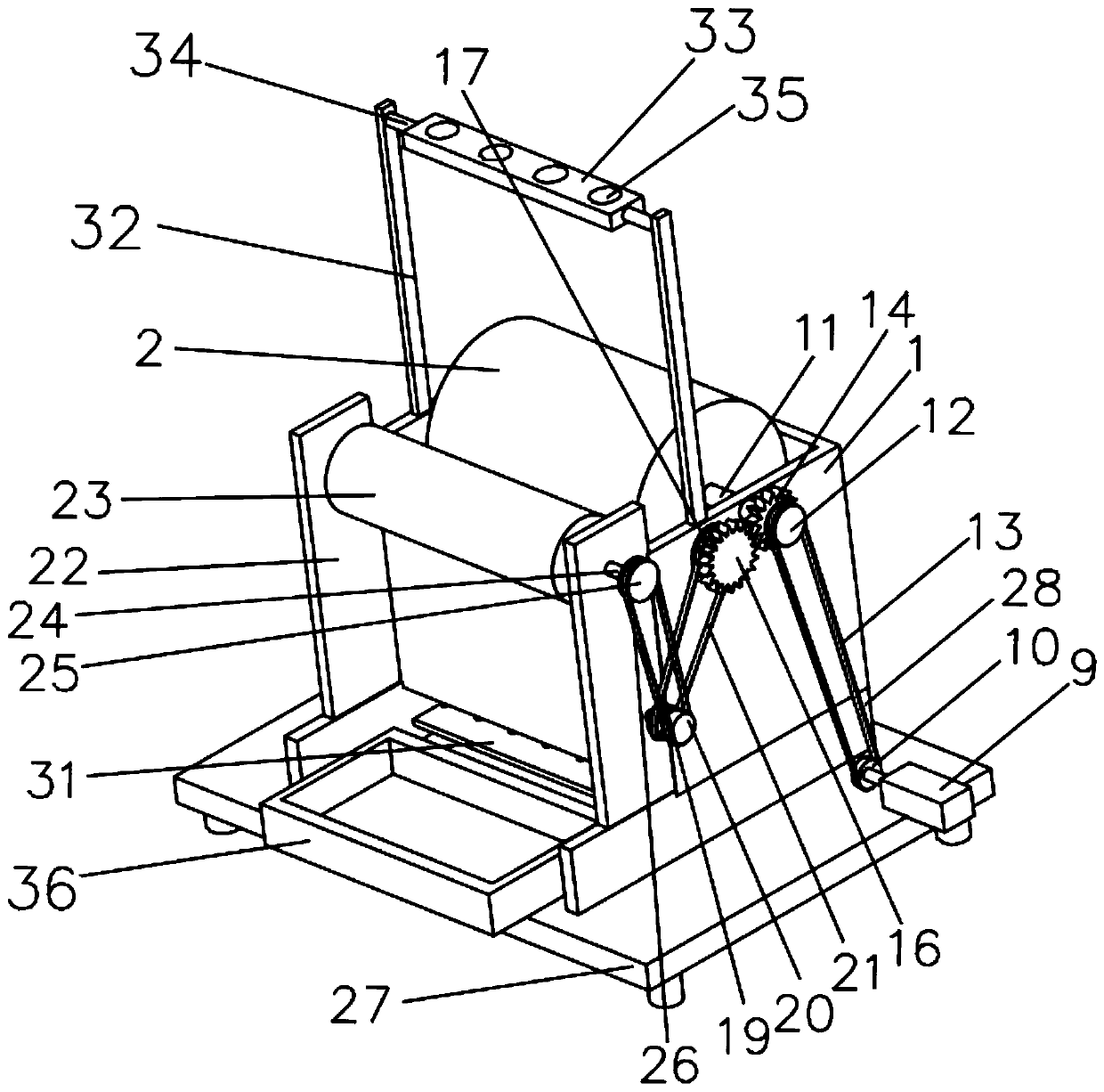

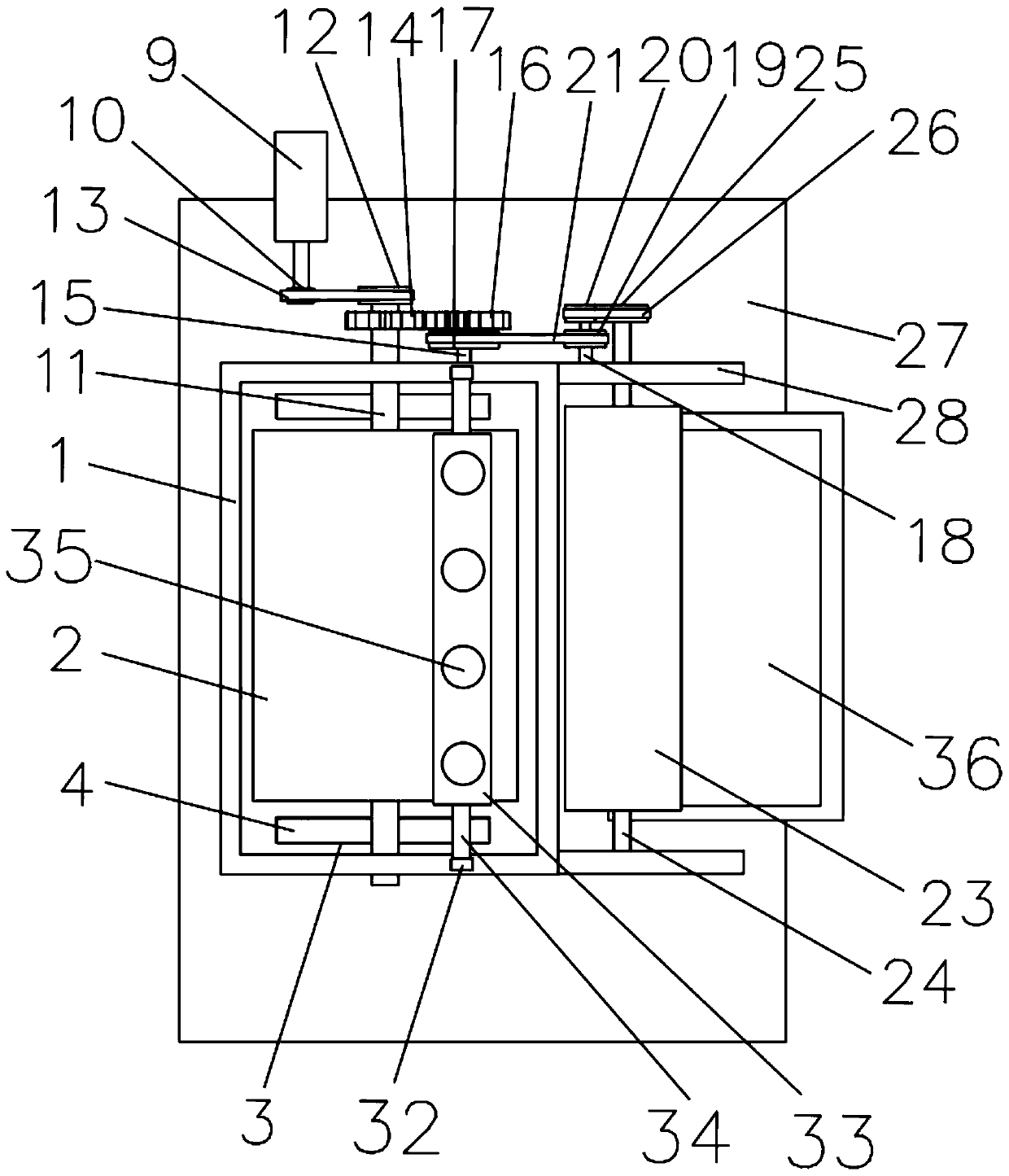

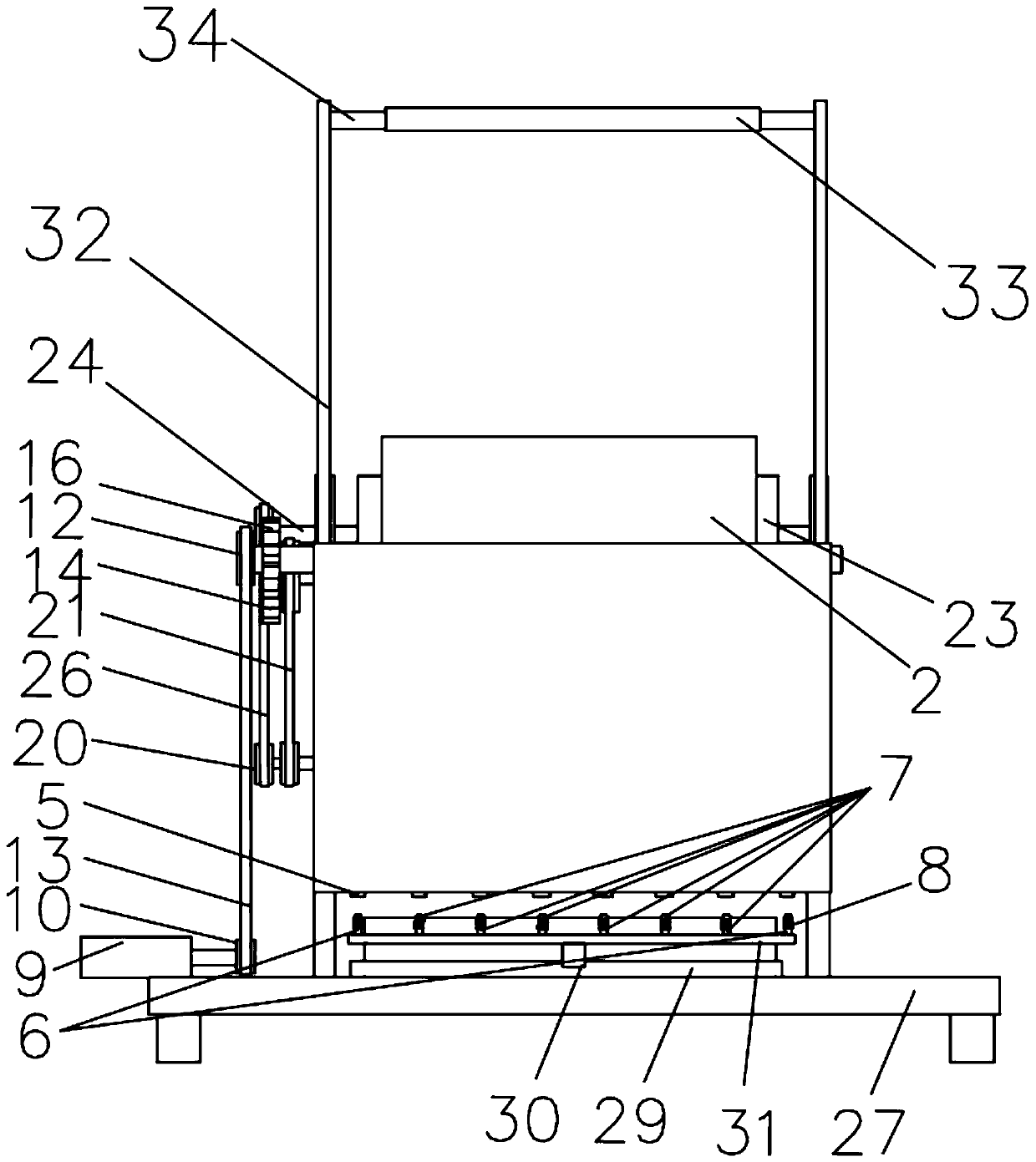

[0022] see Figure 1 to Figure 4, a latex electrodeposition device of the present invention includes a negative electrode pool 1 for holding glue and a drive mechanism, which can continuously add glue into the negative electrode pool 1 during the electrodeposition process to ensure that the negative electrode pool 1 The change of the liquid level is small, the output end of the drive mechanism is provided with a positive electrode reactor 2, which is rotationally connected with the negative electrode pool 1, and the bottom of the negative electrode pool 1 is provided with several strip holes 3 , the inside of the strip-shaped hole 3 is provided with an elastic layer 4, and also includes a plurality of first magnets 5, and a plurality of second magnets 6 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com