Corrugated steel plate composite beam without upper flange and manufacturing method thereof

A technology of corrugated steel plates and composite beams, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of inconvenience, complex construction process, and large amount of steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

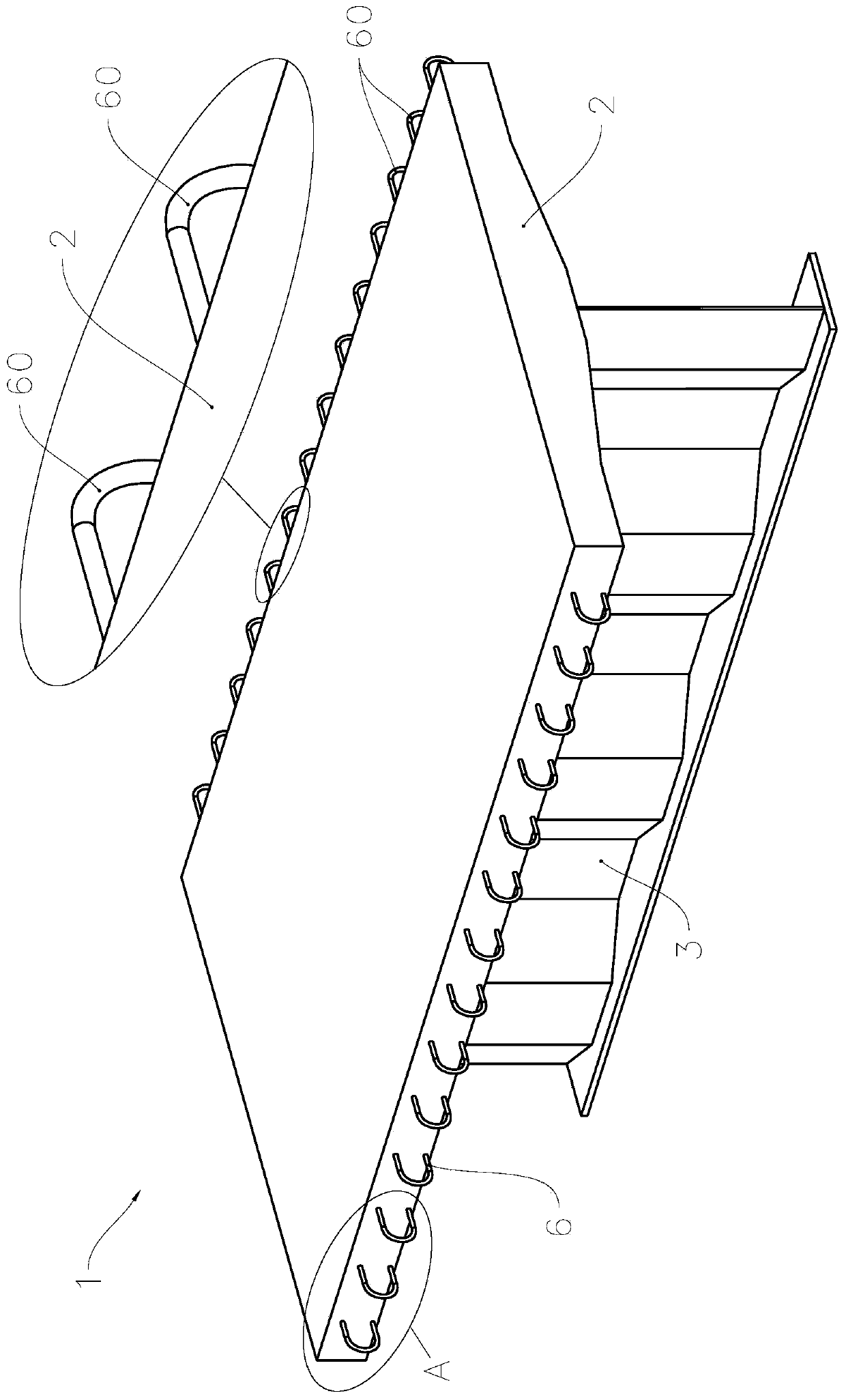

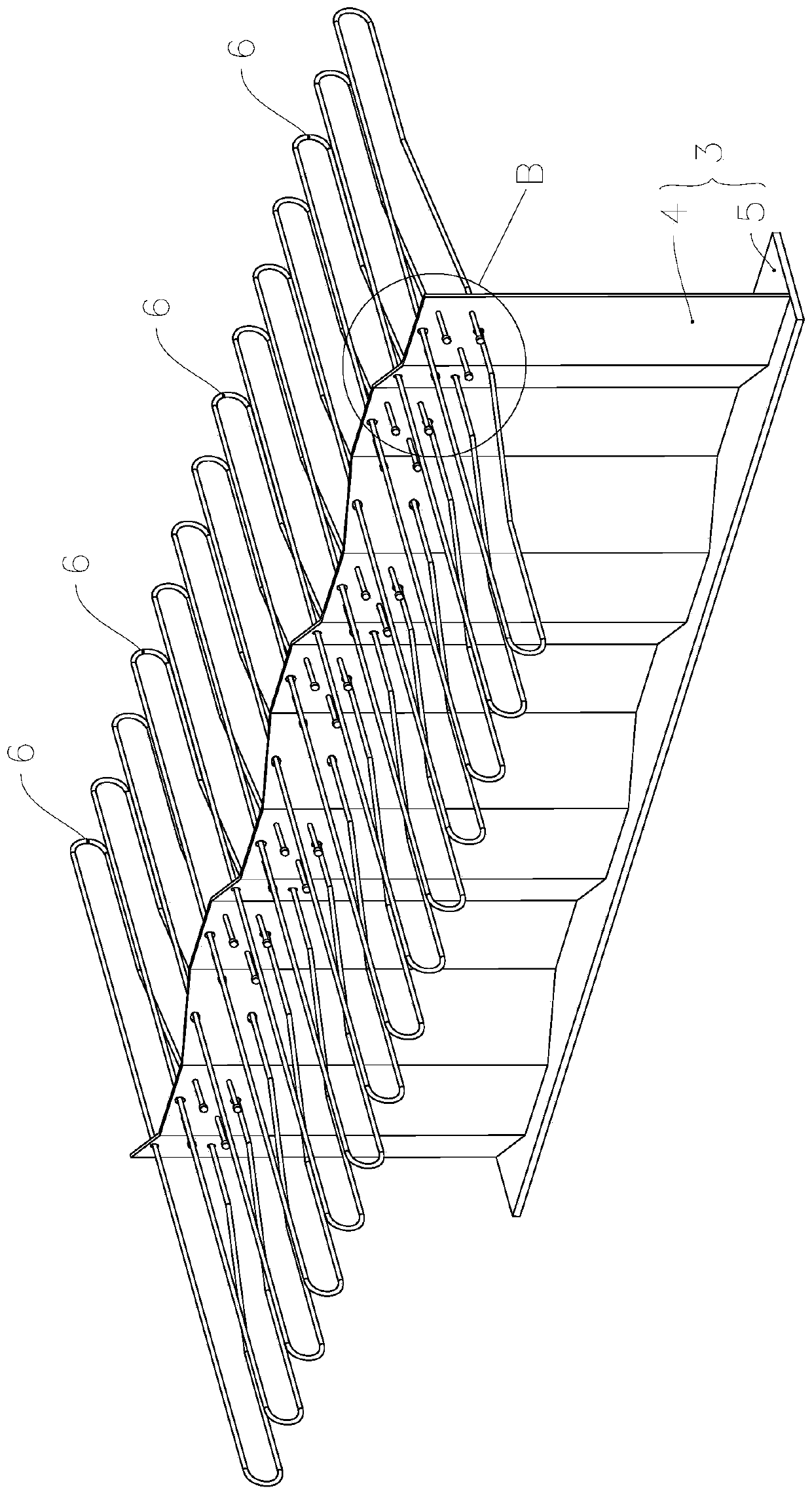

[0031] see Figure 1 to Figure 6 , the corrugated steel plate composite girder 1 of the present invention has no upper flange plate structure, and specifically includes a prefabricated steel girder 3 and a concrete bridge deck 2 fixedly connected with the prefabricated steel girder 3 .

[0032] The prefabricated steel girder 3 includes a web 4 and a bottom plate 5; wherein, the web 4 is a corrugated steel plate arranged vertically along the groove length direction, the bottom plate 5 is a strip-shaped straight steel plate, and the lower edge of the web 4 is connected to the upper surface of the bottom plate 5 Welding is fixed, and the welding trace extends along the length direction of the web 4 to cover the joint surface of the two, so that the web 4 and the bottom plate 5 firmly form an inverted T-shaped structure. In addition, the web 4 and the bottom plate 5 may also be fixedly connected by bolting.

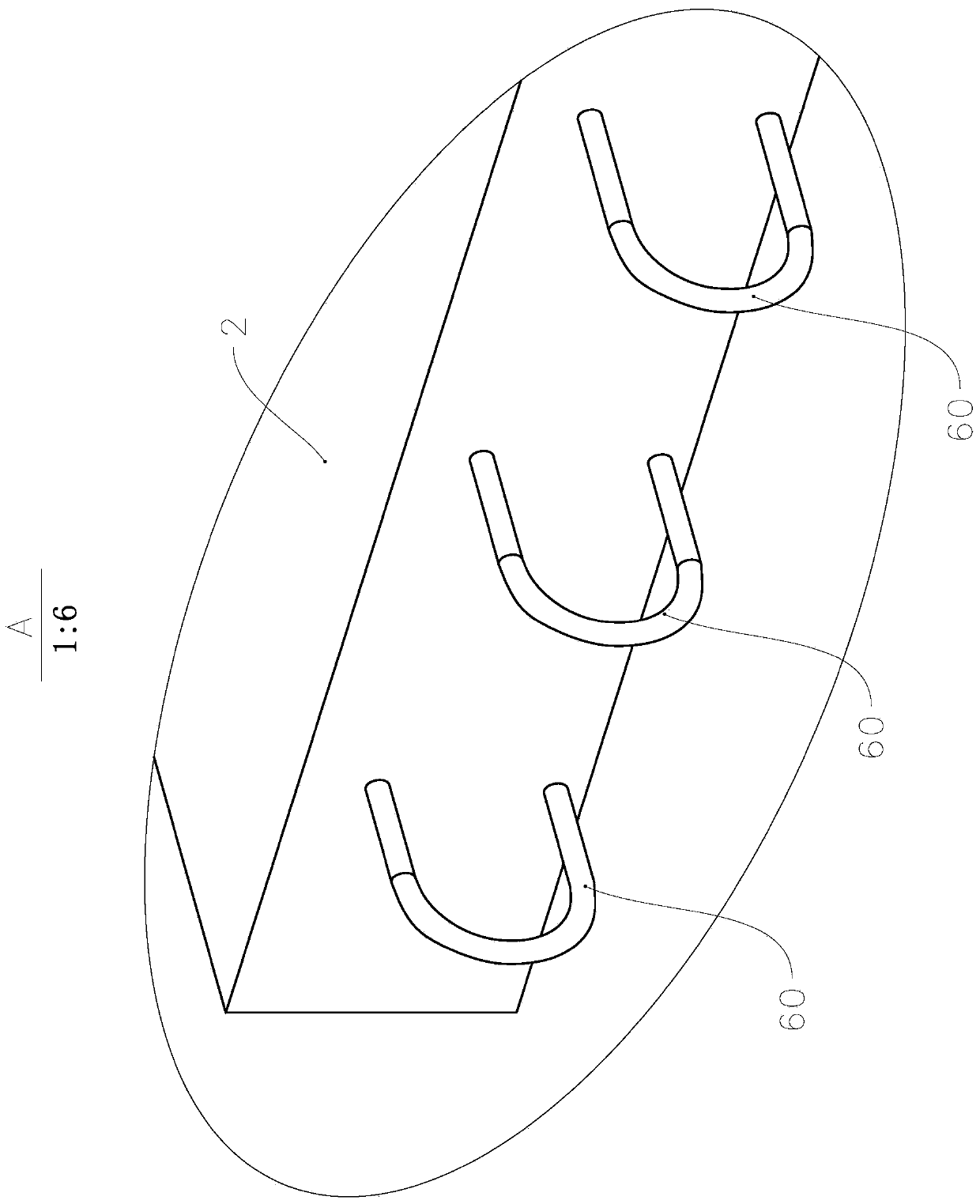

[0033] On the upper end of the web 4, there are a plurality of steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com