Method for processing concrete cast-in-place pile bottom sediment

A cast-in-place pile and concrete technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as increasing pile body settlement displacement, reducing single pile bearing capacity, and affecting pile foundation quality, so as to ensure construction quality, The effect of short construction time, reduced cost and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The connection structure of the present invention will be described in detail below with reference to the drawings and embodiments.

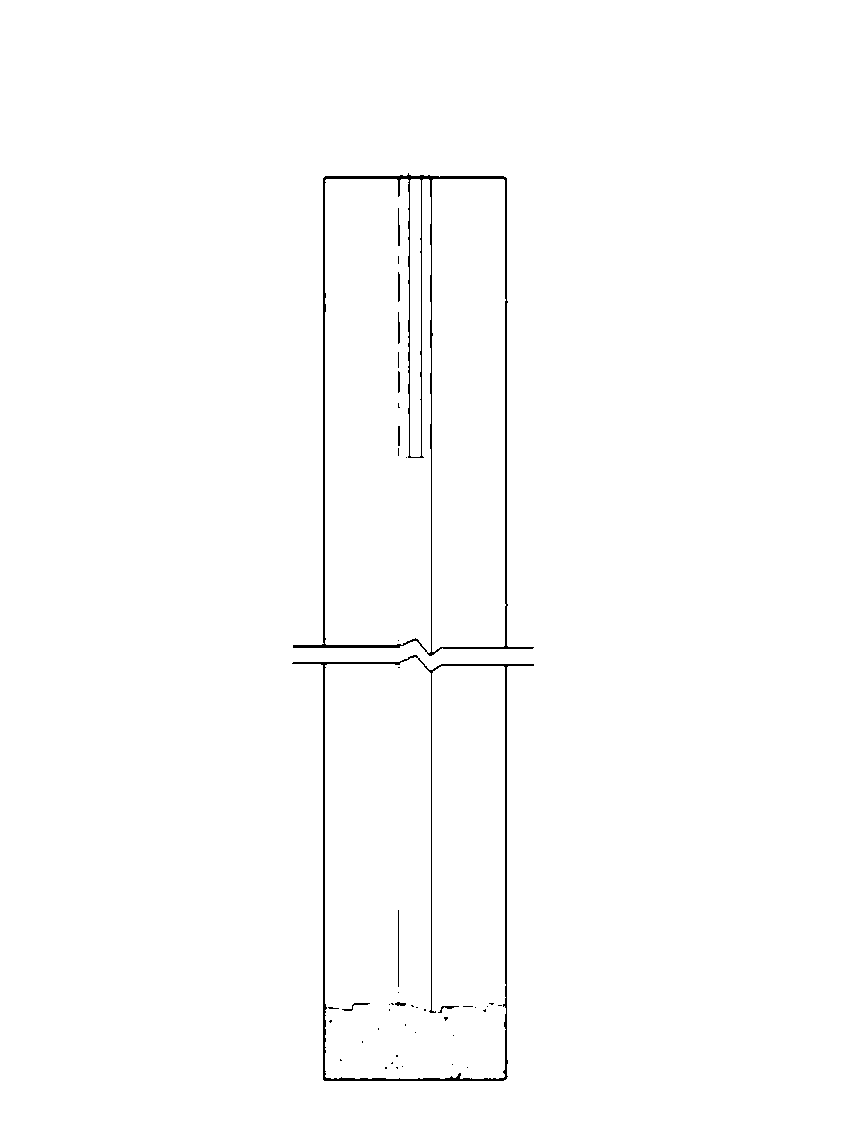

[0026] See attached figure 1 Shown, a kind of method of processing concrete pouring pile bottom sediment of the present invention comprises the following steps:

[0027] 1) Drill holes at the top of the concrete pouring pile (2)

[0028] At the center position of the top of the concrete pouring pile (2), avoid the reinforcement cage inside the concrete pouring pile (2), and drill holes from the top of the pile to the bottom of the pile through drilling equipment to form a pile core borehole (4). (4) Aperture 100mm ~ 150mm;

[0029] 2) Install a grouting hole sealer (3) on the top of the pile core borehole (4)

[0030] Install a grouting hole sealer (3) on the top of the pile core borehole (4), and pressurize the grouting hole sealer (3) to make it seal the top of the pile core hole (4) tightly, leaving only the grout The grouting port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com