Underground pipe gallery pipeline made from low-cost composite material

A technology of composite materials and underground pipe gallery, which is applied in the fields of drainage, gas composite material pipes, heating and water supply, can solve the problems of long demolition and reconstruction period, economic loss, short service life, etc., to improve the efficiency of normal use, The effect of prolonging the service life and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

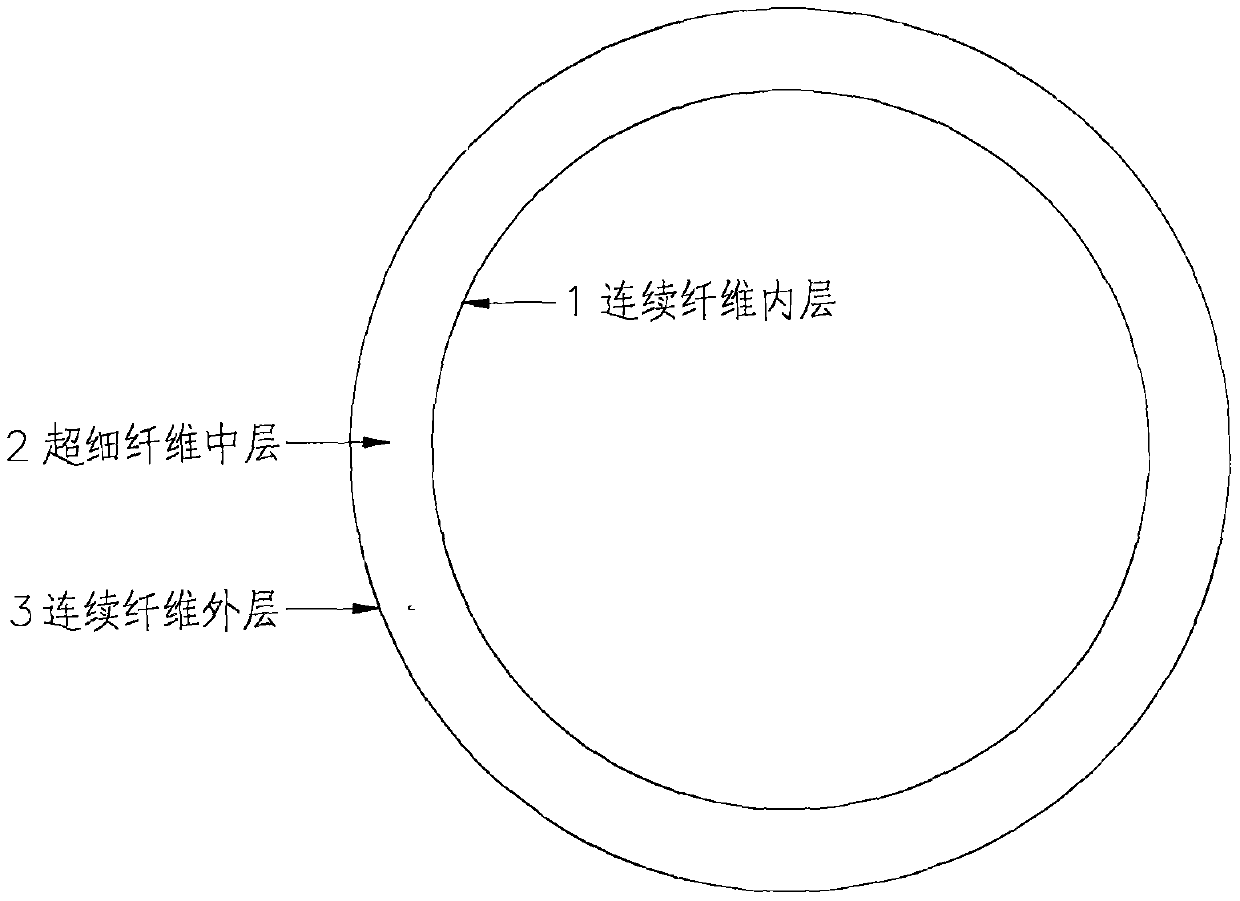

[0012] Referring to the accompanying drawings, the present invention is further described: the ultra-low-cost composite material underground pipe gallery pipeline, the inner layer (1) of the pipeline is formed by winding continuous basalt fibers through the inner mold, and the pipeline is formed by coating a large amount of ultrafine basalt fibers on the outside of the inner layer In the middle layer (2), the outer layer (3) of the pipe is completed by rewinding the continuous basalt fiber outside the middle layer, and the formed pipe enters the outer mold for pressurization, heat preservation and shaping to complete the pipe manufacture.

[0013] The pipeline of the pipe gallery is characterized in that: large-diameter pipes for water supply, reclaimed water, drainage, heat supply, and gas in the underground pipe gallery are all made of continuous and ultrafine basalt fiber composite materials.

[0014] Further, the pipeline of the pipe gallery is characterized in that: the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com