Gas turbine blade comprising V rib-pit composite cooling structures

A composite cooling and gas turbine technology, applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problem of air volume reduction and achieve the effects of reducing blocking ratio, enhancing disturbance, and enhancing cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

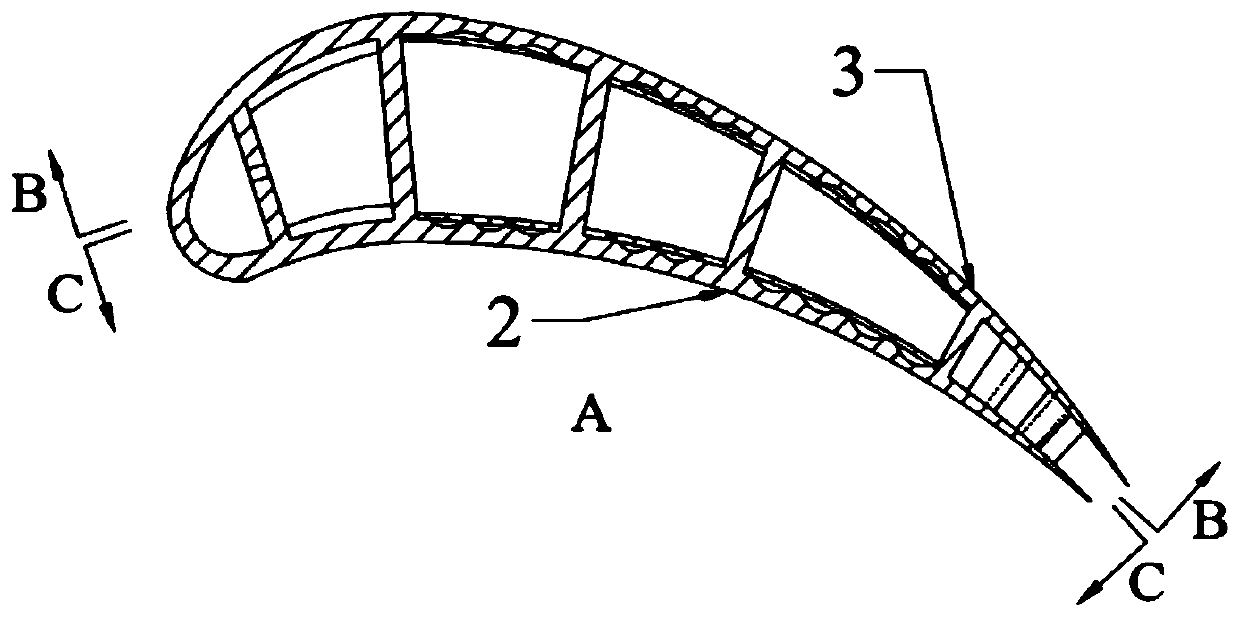

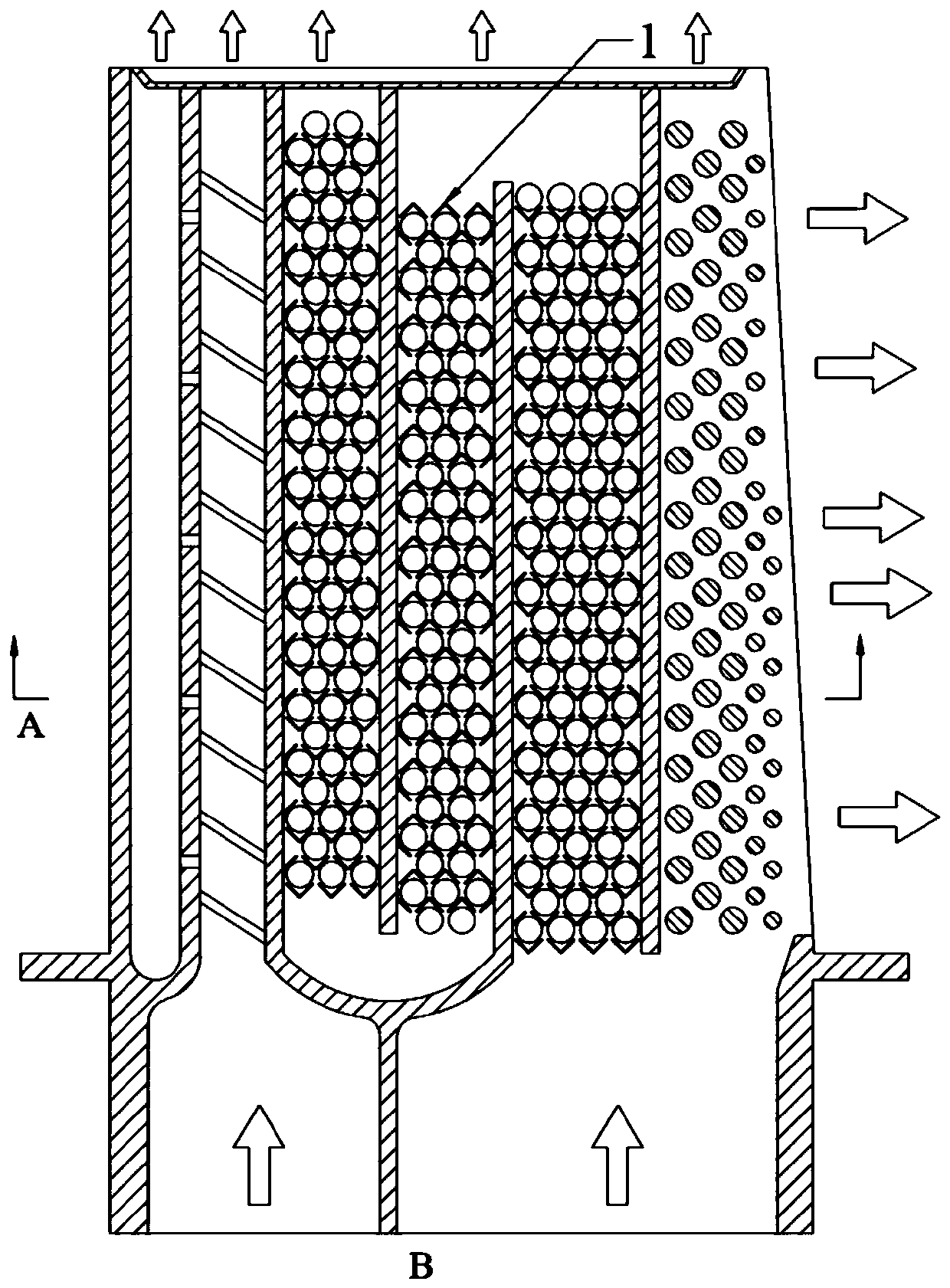

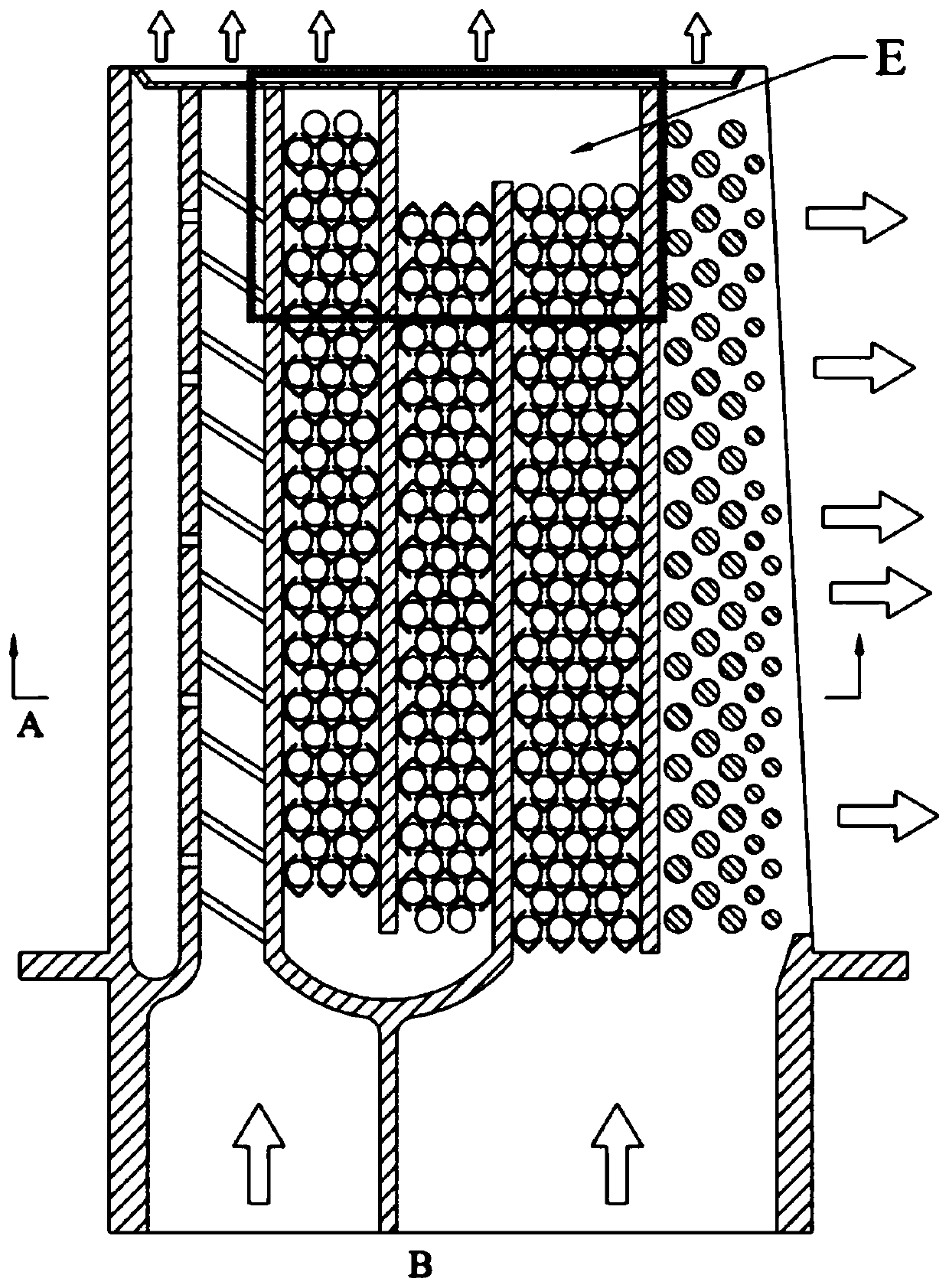

[0021] combine Figure 1-4b , figure 1 It shows a schematic cross-sectional view at A (transverse) of the present invention. The V-rib-dimple composite structure 1 in the present invention is inside the upper wall surface 3 and the lower wall surface 2 in the serpentine cooling channel in the middle of the blade. The diagonal rib cooling structure and internal impingement cooling structure of the leading edge of the blade and the cylindrical rib cooling structure of the trailing edge of the blade are similar to the interior of the conventional blade.

[0022] figure 2 A schematic diagram of the longitudinal section at B of the present invention is shown, which is a section view of the inner side of the upper wall of the blade. The cooling air flows in from the root of the blade, and part of the gas enters the cooling channel at the leading edge of the blade. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com