Fuel oil supply system

A technology for fuel supply and oil wells, applied in the direction of charging systems, liquid fuel feeders, engine components, etc., can solve the problems of increasing the cost of fuel supply systems, metal material products are not environmentally friendly, and metal materials are expensive, etc., to achieve simple structure , low cost, simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

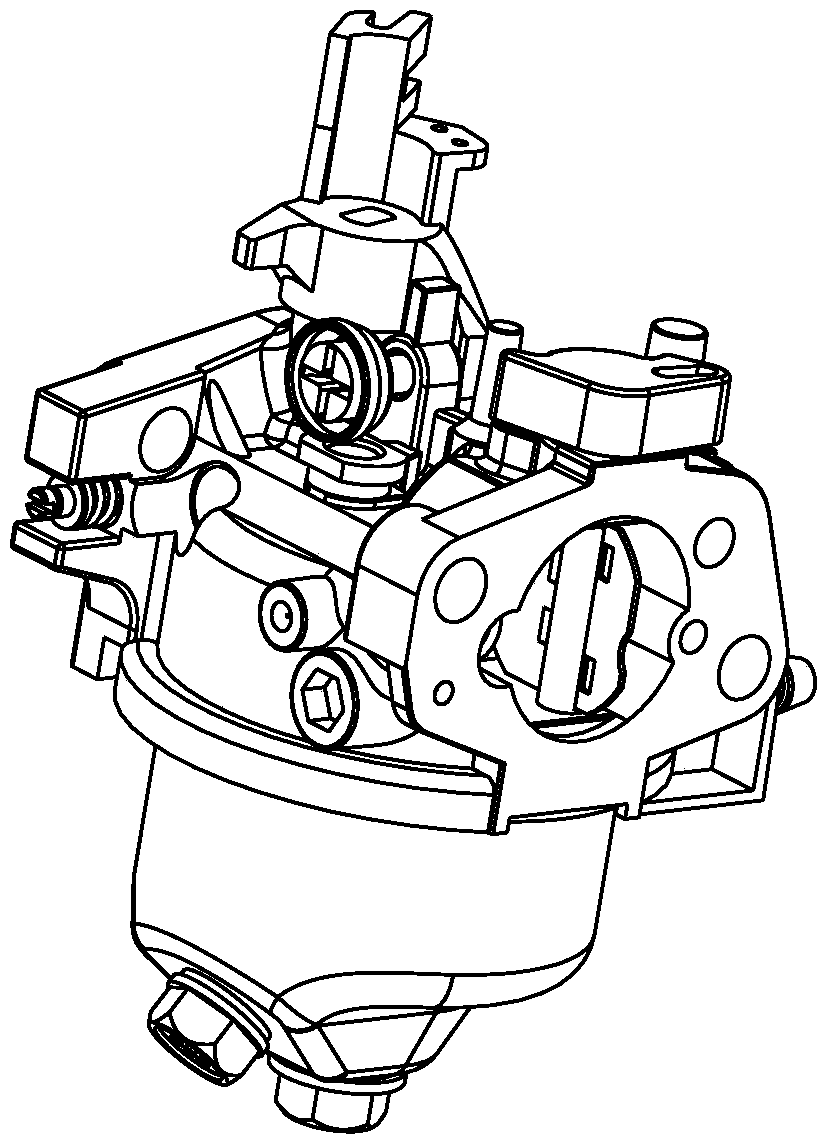

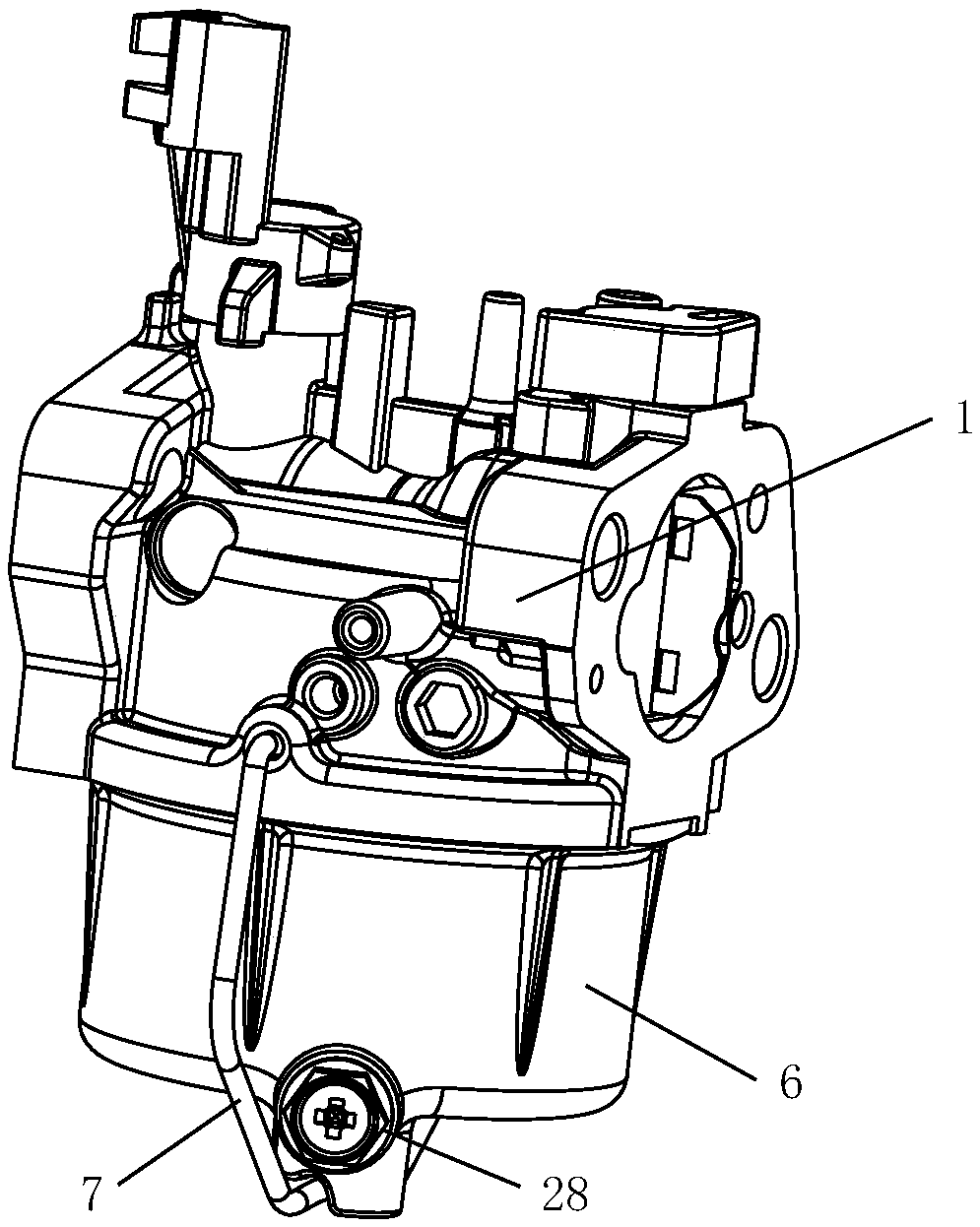

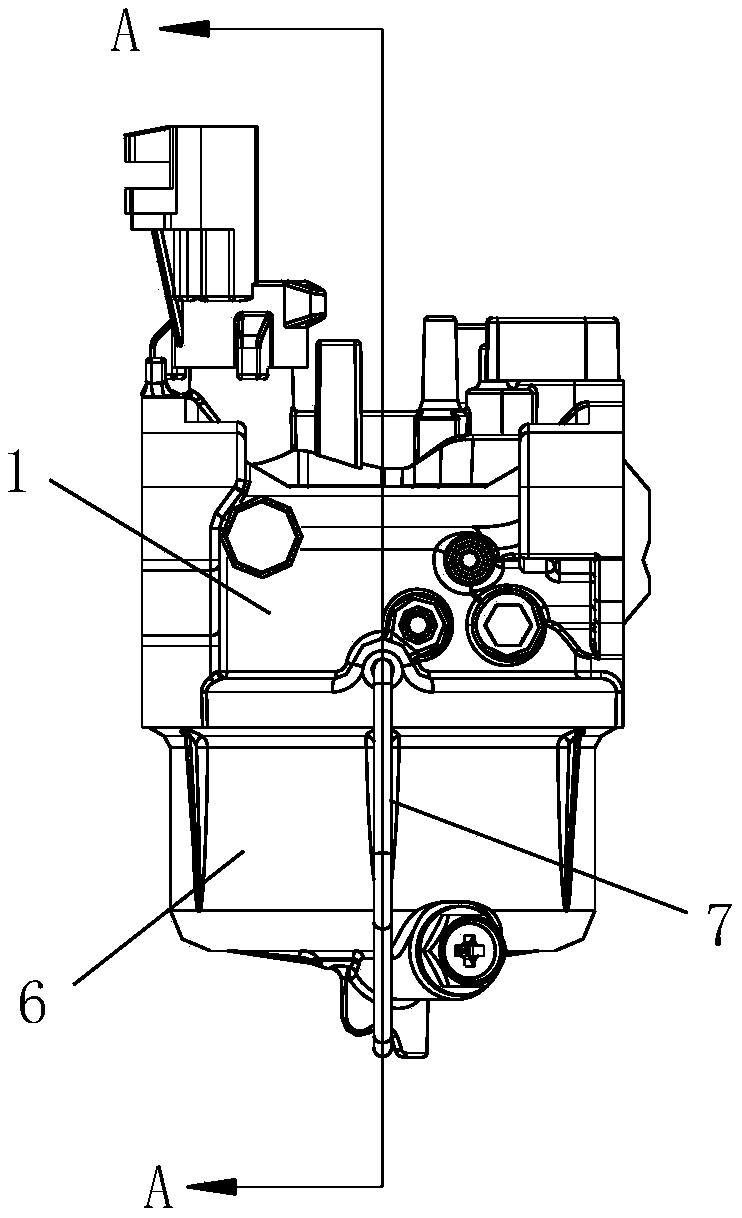

[0063] see Figure 2-Figure 7 , figure 2 It is a perspective view of a fuel supply system according to an embodiment of the present invention, image 3 for figure 2 front view of Figure 4 for image 3 left view of Figure 5 for image 3 The A-A section diagram, Figure 6 for Figure 4 The B-B section diagram, Figure 7 for Figure 4 The C-C section diagram. The fuel supply system of the present invention comprises a main body 1, a lower cover 6, a main oil well 3 and a main nozzle 2, the lower cover 6 is sealed and connected to the main body 1 through a lower cover connector 7, and the lower cover 6 is connected to the main body 1 A body sealing ring 4 is installed at the joint, and a float 5 is arranged in a closed space formed by the lower cover 6 and the body 1 , and the float 5 is connected with the main oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com