System and method for positioning fatigue crack in plate like structure based on ipsilateral ultrasonic mixing wavelet

A technology of fatigue cracks and frequency mixing, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and processing detection response signals. It can solve problems such as undiscovered patent documents and achieve Good for reference, improve utilization rate, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

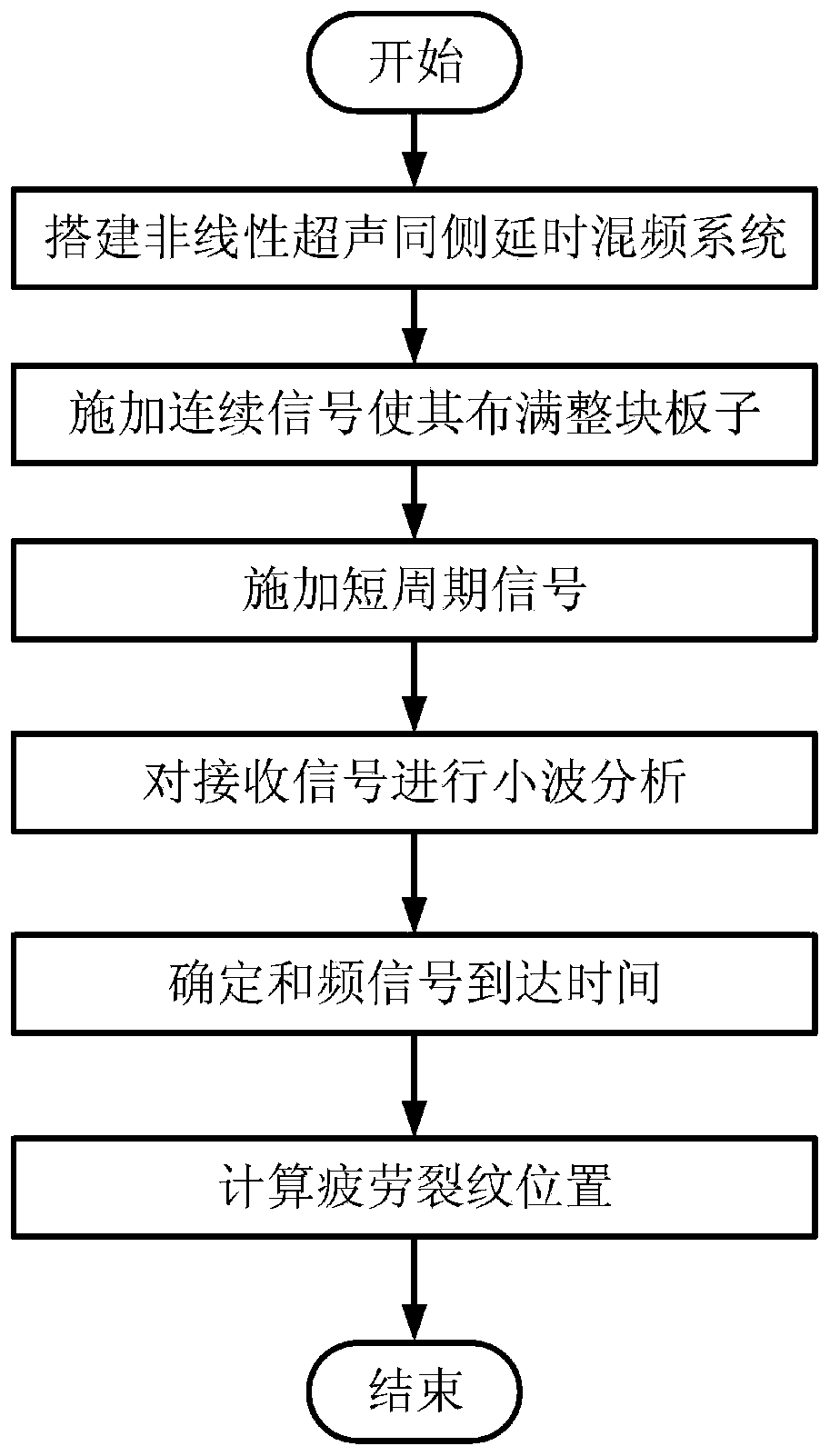

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

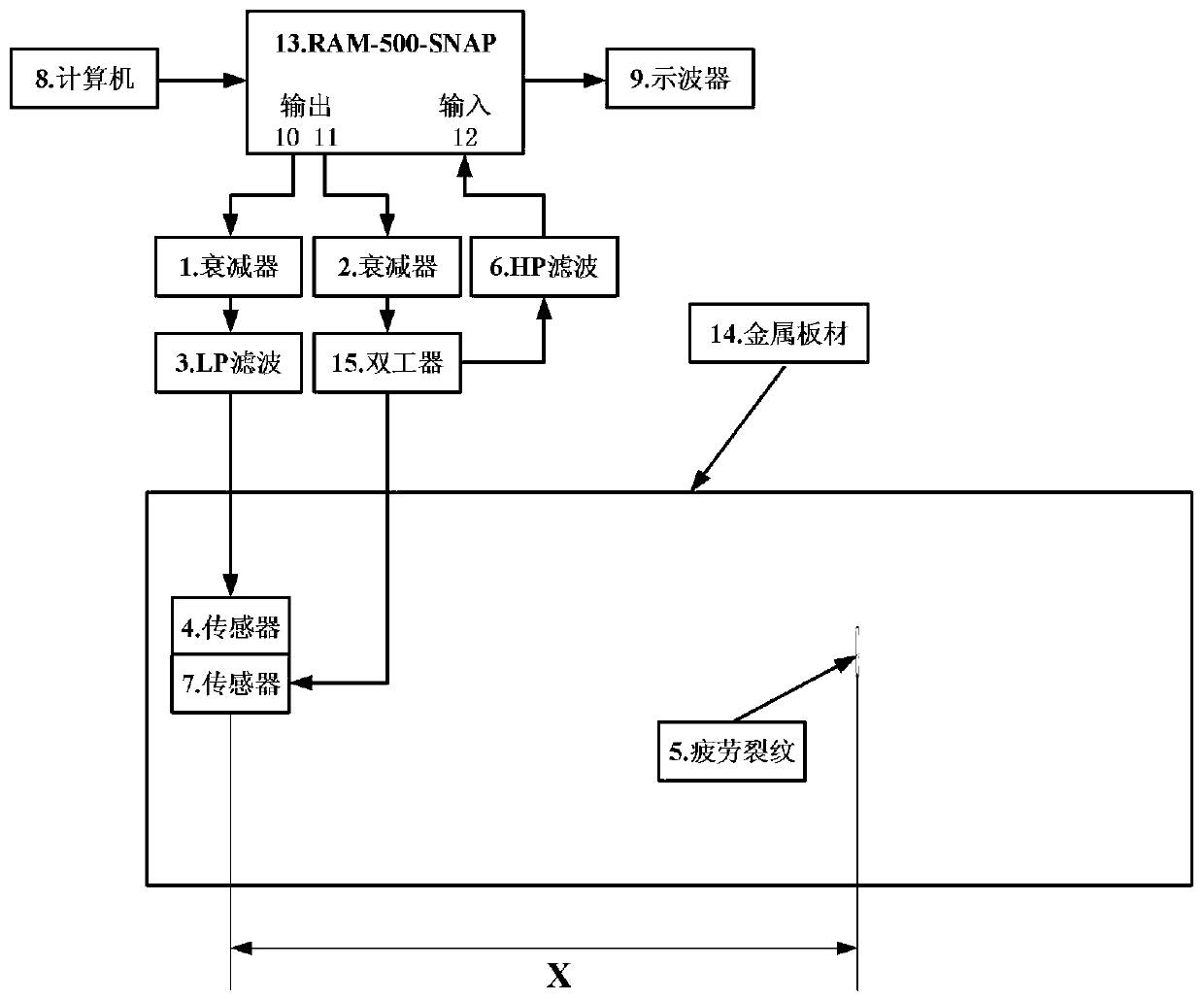

[0031] A system for locating fatigue cracks in plate structures based on the same-side ultrasonic mixing wavelet. 14, a duplexer 15, a high-pass filter 6 and an oscilloscope 9, the computer is connected to the nonlinear ultrasonic instrument, the nonlinear ultrasonic instrument is provided with two radio frequency output terminals and one radio frequency input terminal 12, and the two radio frequency output terminals include the first The radio frequency output terminal 10 and the second radio frequency output terminal 11, the first radio frequency output terminal and the second radio frequency output terminal are respectively connected with a left side attenuator 1 and a right side attenuator 2, and the left side attenuator and the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com