Battery box system with heating function

A battery box and functional technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve problems such as fire accidents, failure to realize heating functions, and unusable batteries, and achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

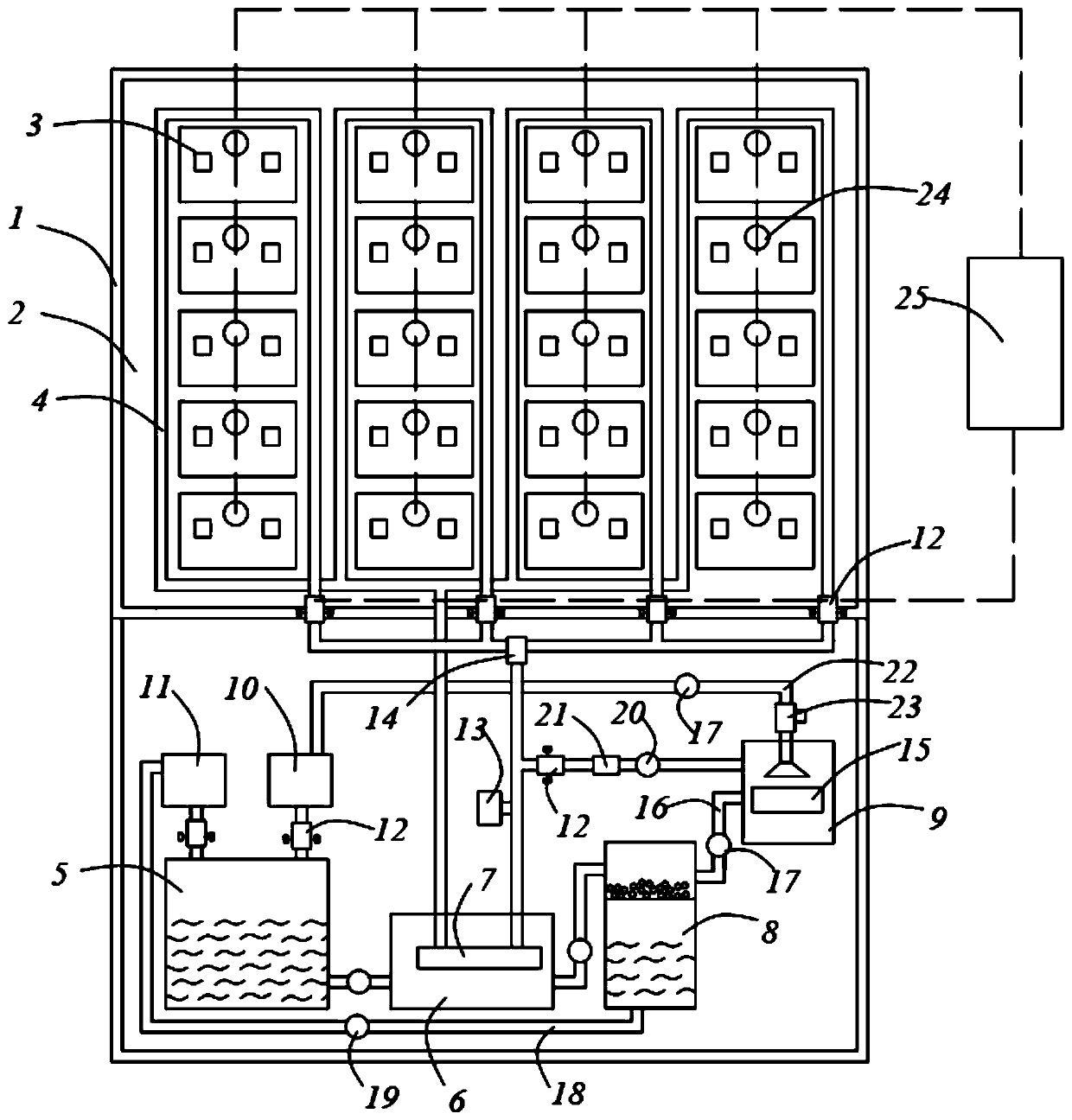

[0018] Such as figure 1 A battery box system with a heating function is shown, including a battery box 1, a battery holder 2 arranged in the battery box 1, and a plurality of cells 3 arranged on the battery holder 2. The battery 3 is divided into several battery packs, and a heating pipe 4 is arranged next to each of the battery packs, and multiple heating pipes 4 are connected in parallel to share the same inlet and outlet, and a heating reaction device is arranged next to the battery box 1, The function of the heating reaction device is to raise the temperature in the battery case 1 in a low temperature environment to ensure that the battery can be charged and discharged normally; the heating reaction device includes a mixing box 5, a condensation box 6, and a heat exchanger 7 , filter box 8, drying box 9, raw material box 10 and water tank 11, in the described ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com