Honeycomb amplification type fiber push-out device and working method thereof

A push-out, honeycomb-type technology, applied in measurement devices, piezoelectric/electrostrictive or magnetostrictive motors, instruments, etc., can solve the problems of easy instability, low precision, fiber damage, etc. Inertia effect, large output force and displacement, uniform force distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

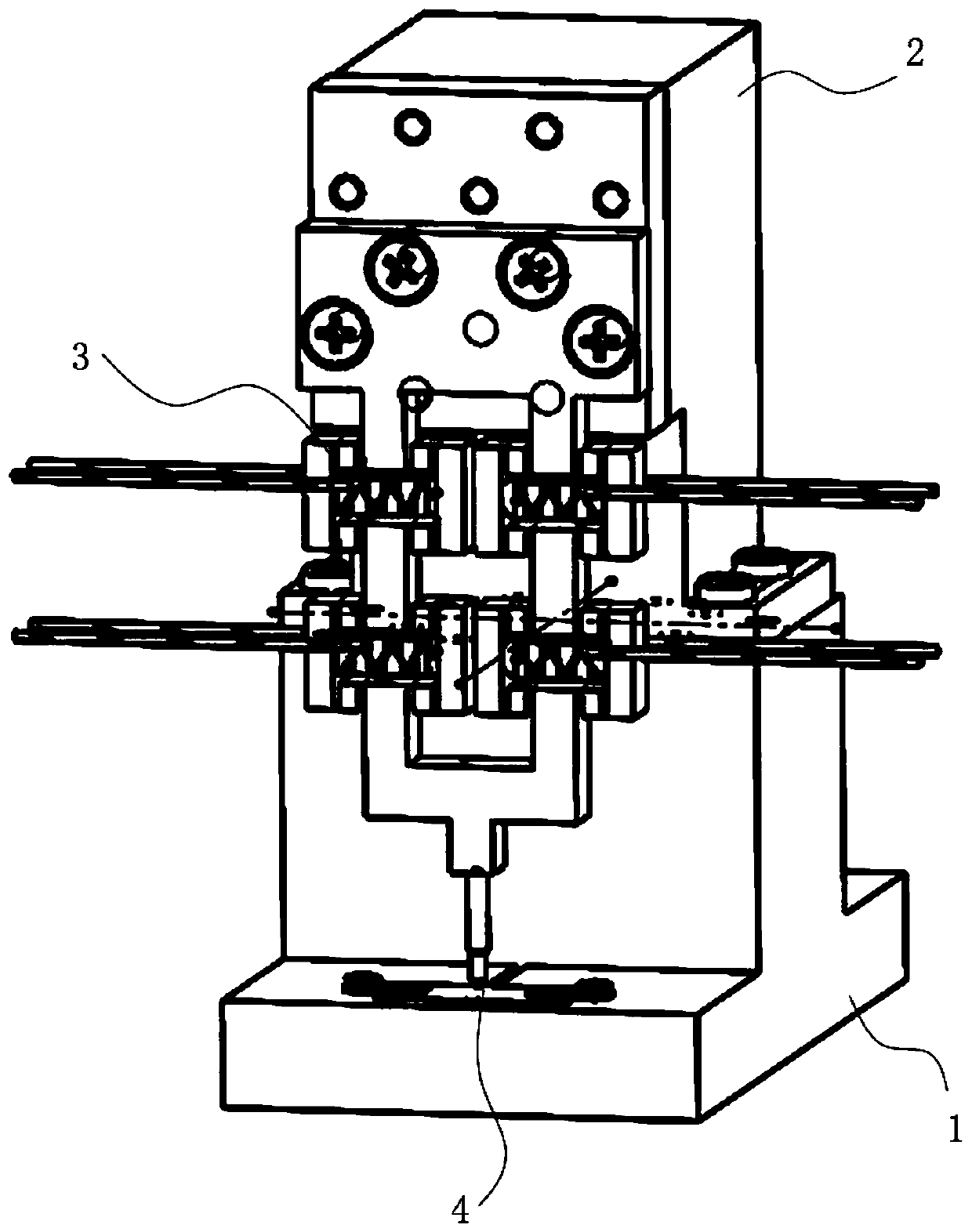

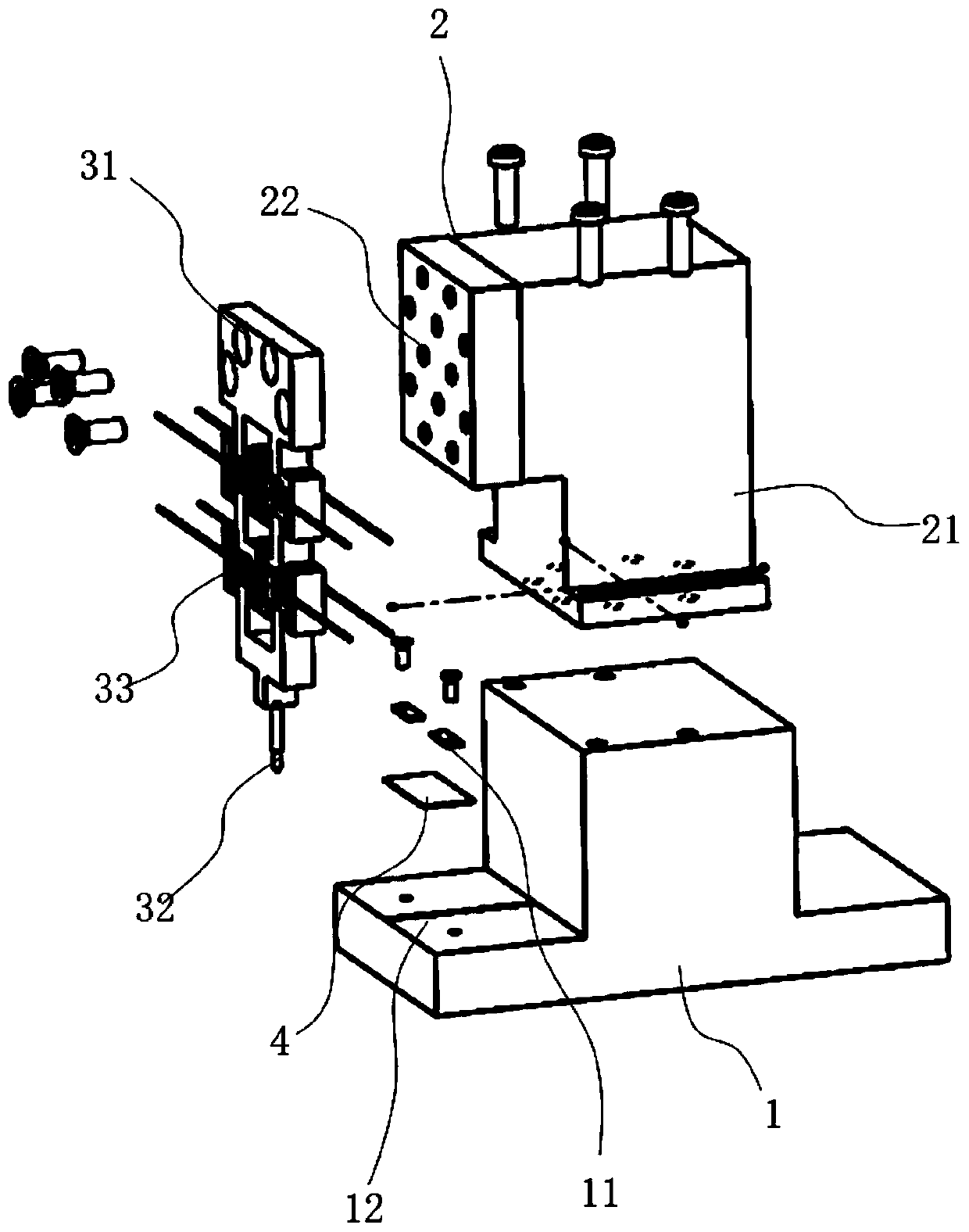

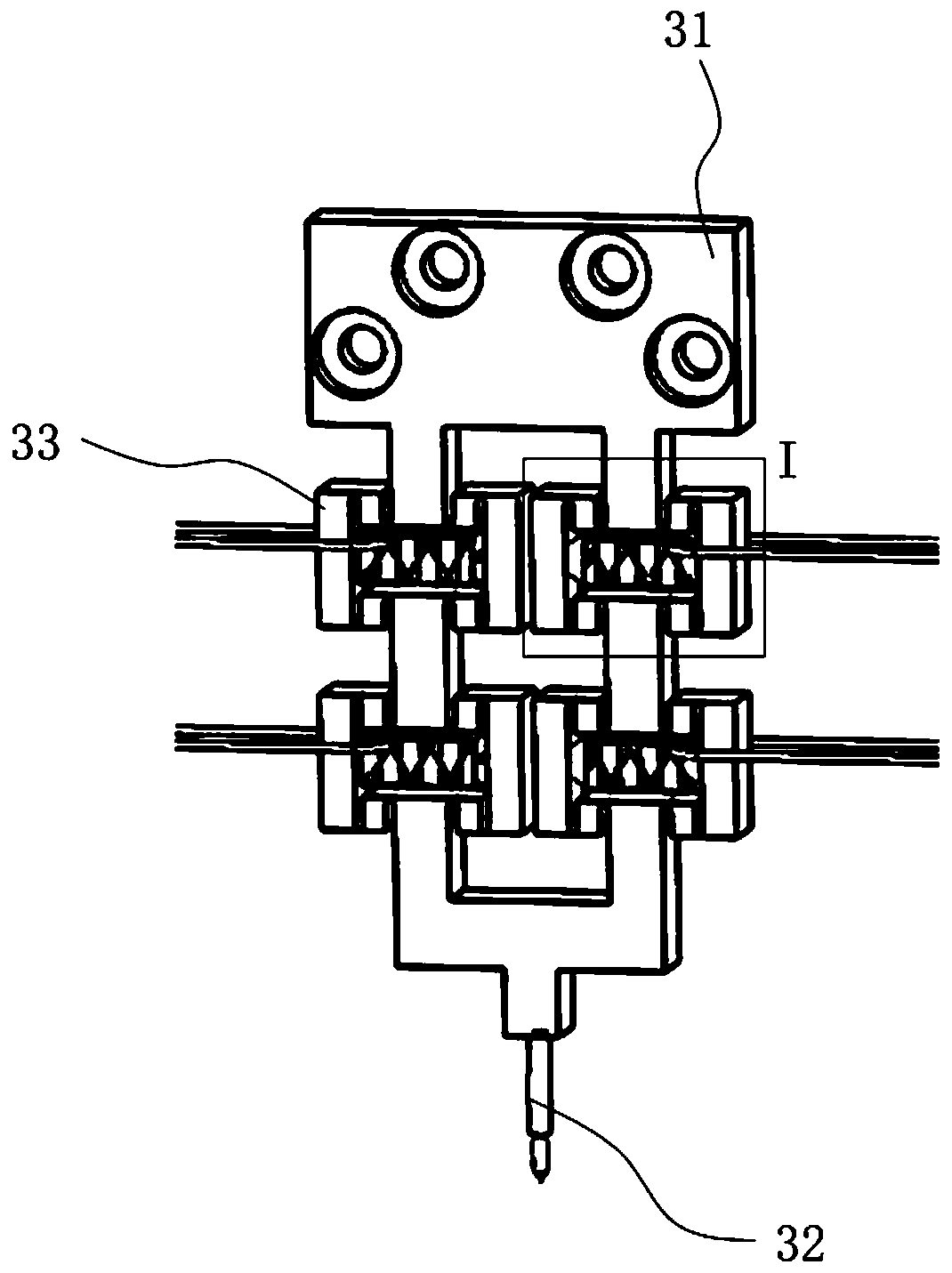

[0037] Such as figure 1 and 2 As shown, the present invention provides a honeycomb amplified fiber pushing device, which includes a workbench 1 , a manual adjustment micro-motion platform 2 and a honeycomb displacement output mechanism 3 .

[0038] The manual adjustment micro-motion platform 2 is fixed on the workbench 1, and the cellular displacement output mechanism 3 is fixed on the front side of the manual adjustment micro-motion platform 2. By adjusting the manual adjustment micro-motion platform 2, the cellular displacement output mechanism 3 is driven to move up and down.

[0039] Specifically, the workbench 1 has a front-rear symmetrical structure, the vertical section in the front-rear direction is an inverted T shape, and the surface of the middle part is higher than the surfaces of the front part and the rear part. The manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com