Mounting rack for large boring row, and quick installation method thereof

A mounting frame and boring row technology, applied in the field of mechanical processing, can solve the problems of fixed circular boring row safety hazards, equipment accidents and safety accident hazards, machine tool overload accidents, etc., so as to shorten auxiliary time, avoid equipment accidents, reduce Effects of equipment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The installation frame and quick installation method for a large boring row according to the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

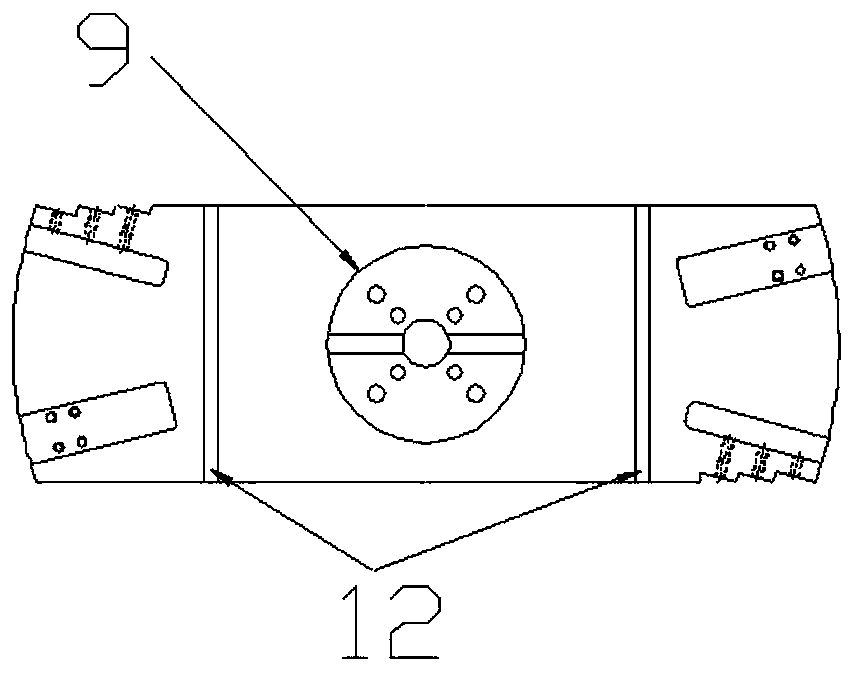

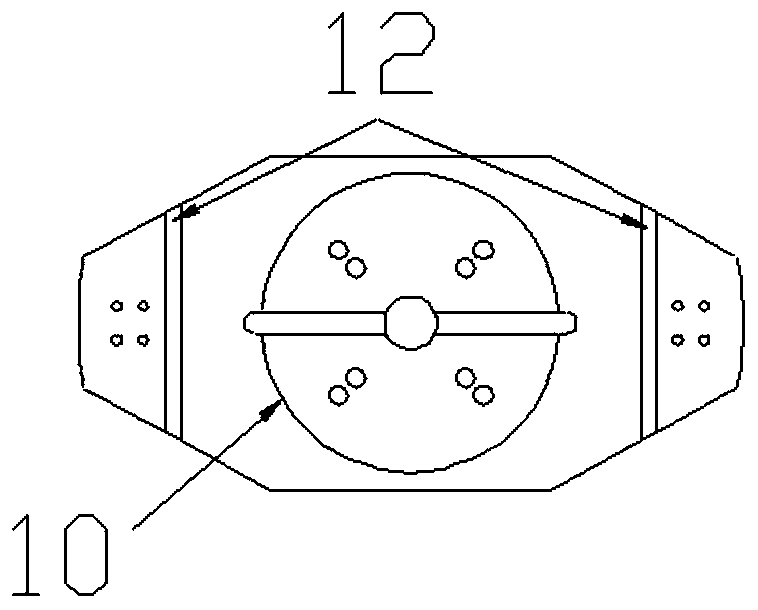

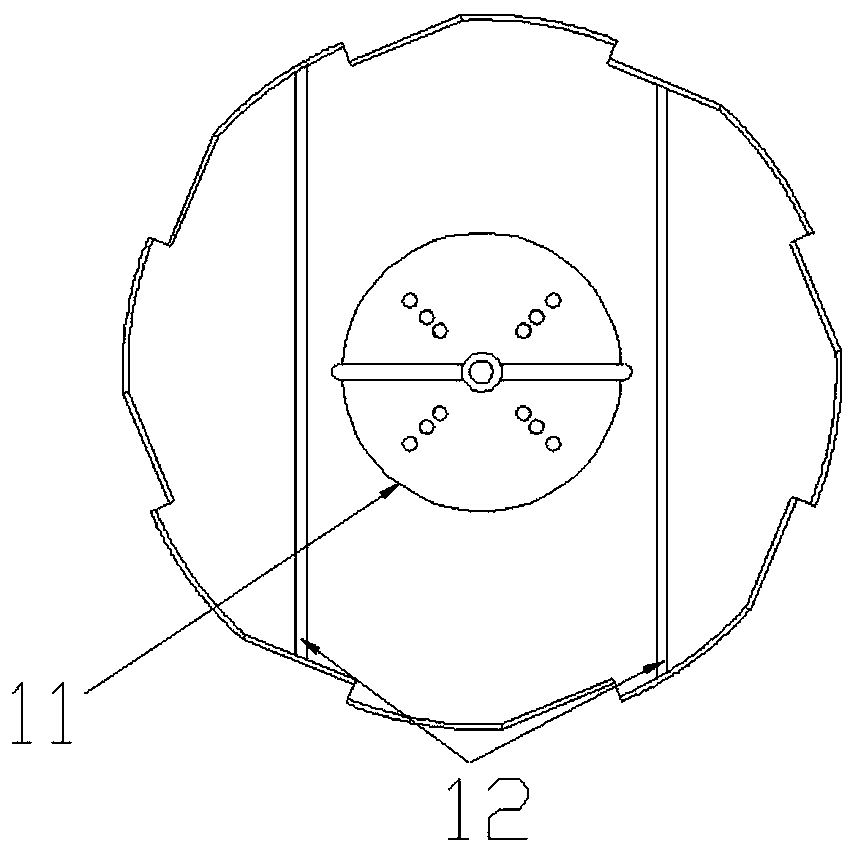

[0076] Please refer to Figure 4 , Figure 5 and Figure 6 , the installation frame of the present invention is fixed on the machine tool table, and mainly includes a base 1, a base 2, a left frame 3, a right frame 4, a top column assembly 5, two adjustable positioning support assemblies 6, and two rotating blocks Assembly 7 and a plurality of protective positioning support assemblies 8 .

[0077] The base 1 is fixed on the machine table; the base 2 rests on the base 1 . The left bracket 3, the right bracket 4, the top column assembly 5 and the two adjustable positioning support components 6 are fixed on the upper plane of the base 2, and the left bracket 3 and the right bracket 4 are respectively arranged on On both sides of the front part of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com