Integrated treatment device and method for liquid garbage

A treatment device and garbage technology, applied in anaerobic digestion treatment, chemical instruments and methods, filtration treatment, etc., can solve the problems that liquid garbage cannot be recycled, secondary pollution, and increase the cost of liquid garbage treatment, etc., to achieve improved stability Performance and reliability, improvement of purification efficiency, and improvement of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

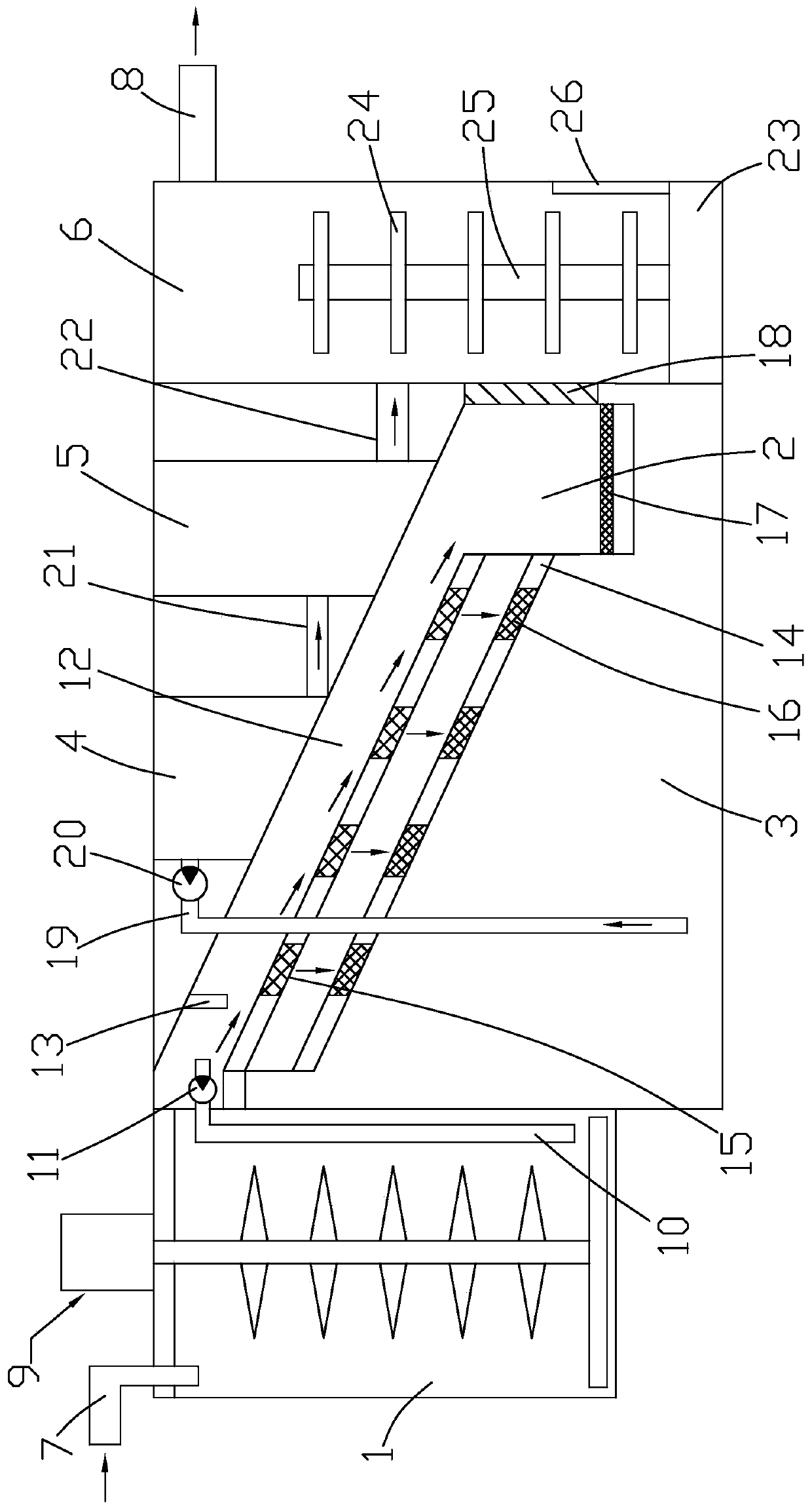

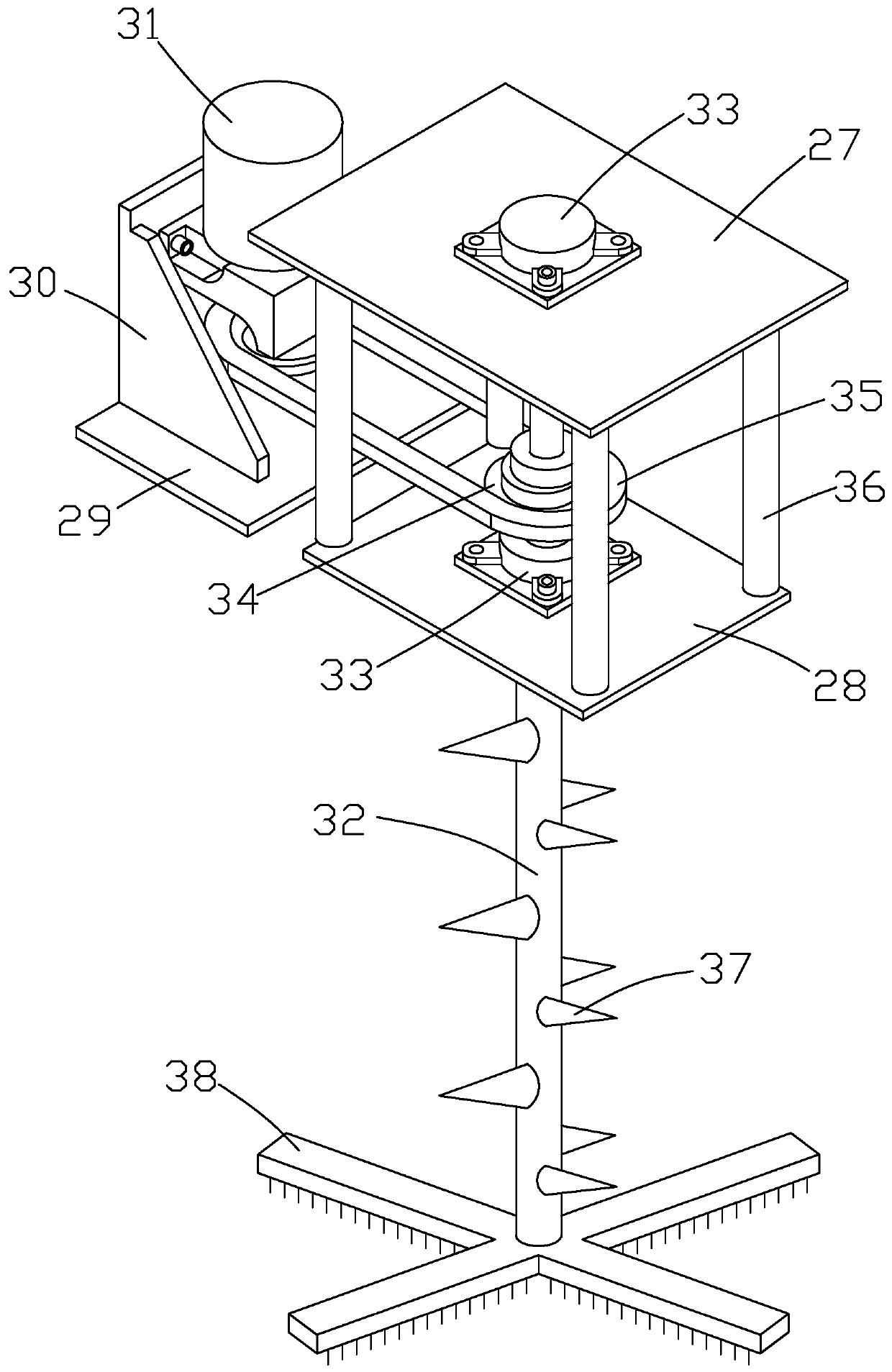

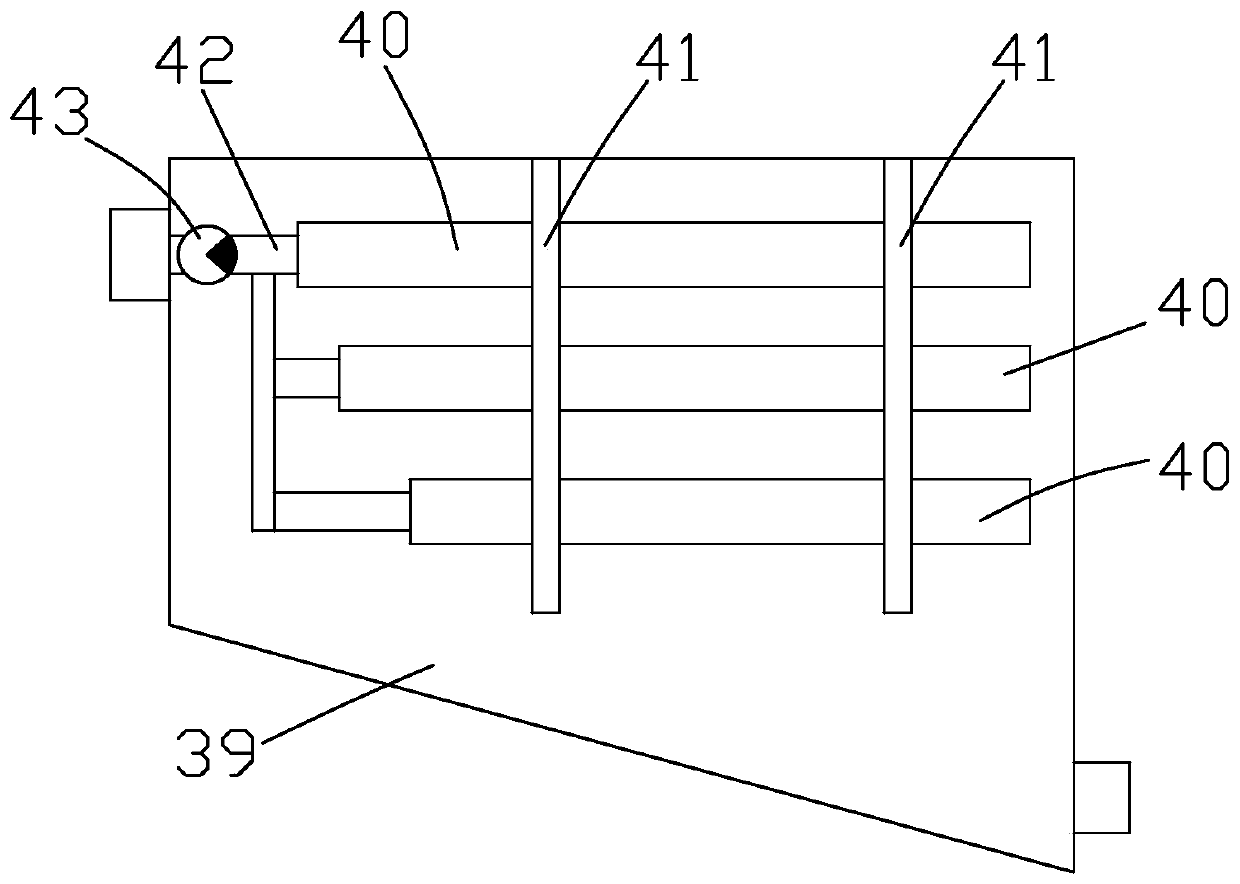

[0055] Such as Figure 1 to Figure 6 As shown, it is a kind of integrated treatment device for liquid garbage of the present invention, comprising a stirring tank 1, a filter tank 2, an anaerobic tank 3, an ultrafiltration device 4, a nanofiltration device 5 and an evaporation pond 6, and the stirring tank 1 is provided with an advanced Water pipe 7 and stirring device 9, stirring device 9 comprises motor 31, first positioning plate 27, second positioning plate 28 and rotating shaft 32, and motor 31 is fixedly connected on the inner side of U-shaped block 30, and U-shaped block 30 is fixedly connected on base plate 29 On the top surface of the top surface, the motor 31 is connected with a driving wheel, the second positioning plate 28 is fixedly connected to one side of the base plate 29, the first positioning plate 27 is fixedly connected to the top of the second positioning plate 28 through the support column 36, the first positioning plate Limiting blocks 33 are arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com