Municipal sludge regeneration and resourceful treatment device

A technology for regenerating resources and treatment devices, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., which can solve the problem that organic energy is not well utilized and increase the input of sludge incineration heat. , the problem of difficult to completely remove the sludge gap, etc., to achieve the effect of reducing energy input, reducing heat, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

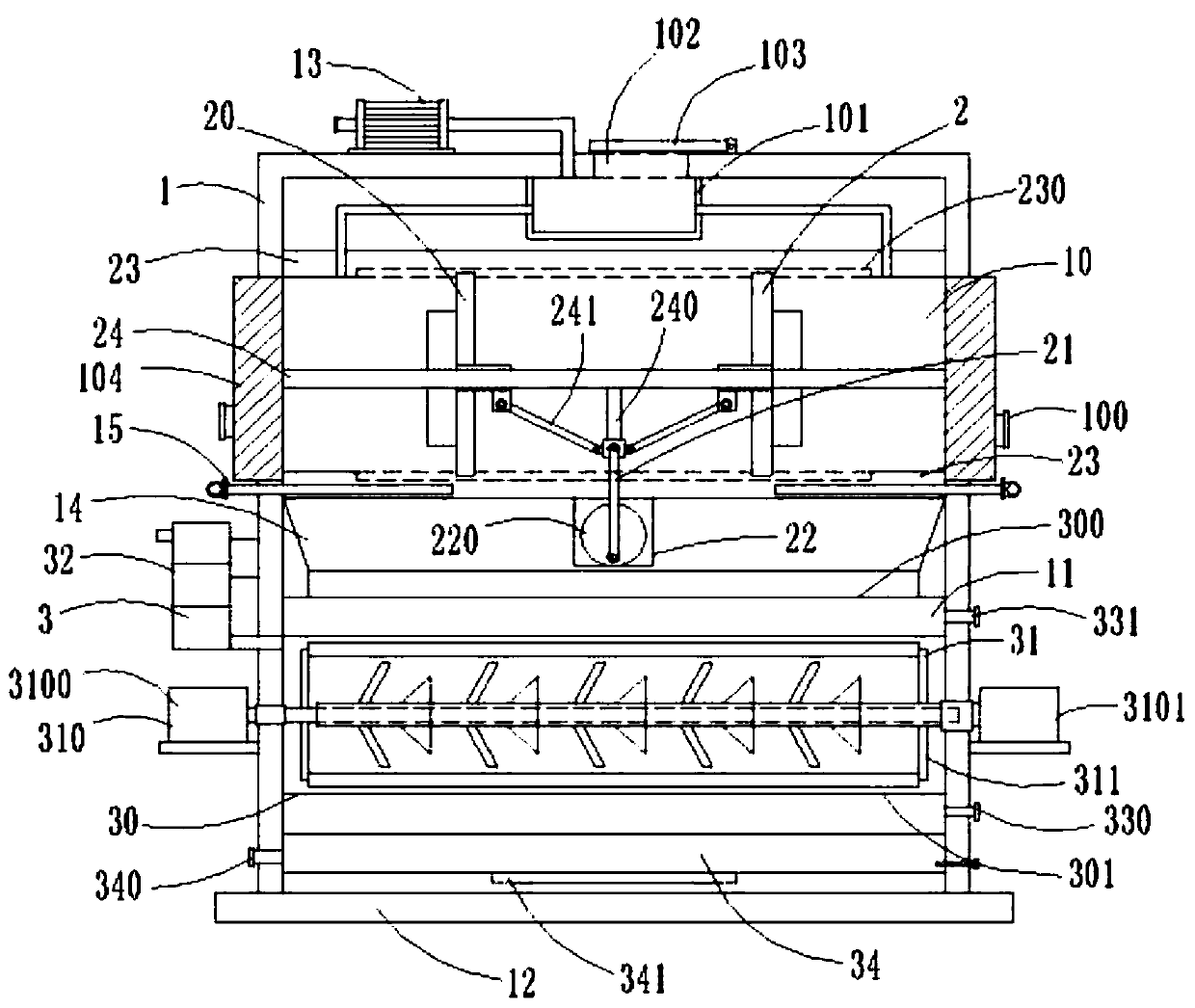

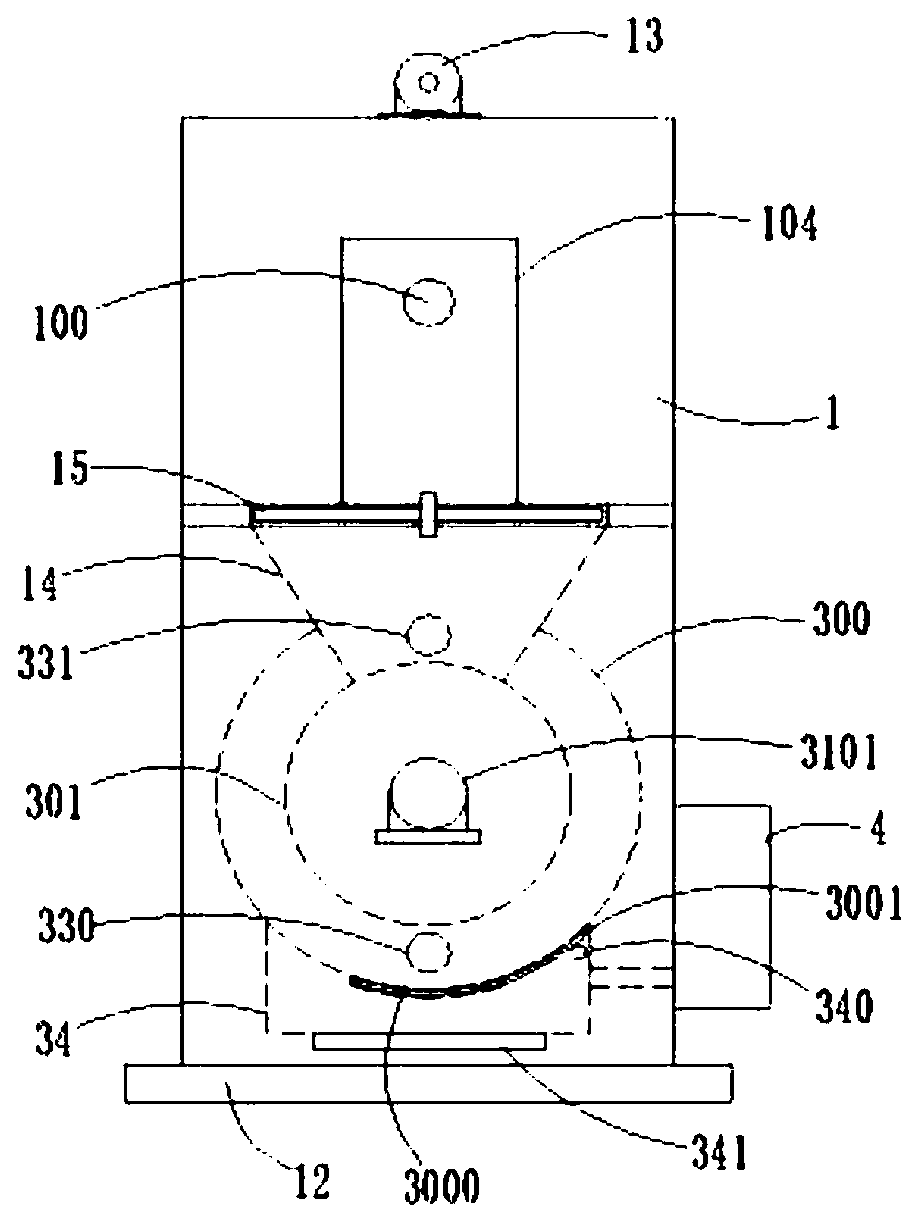

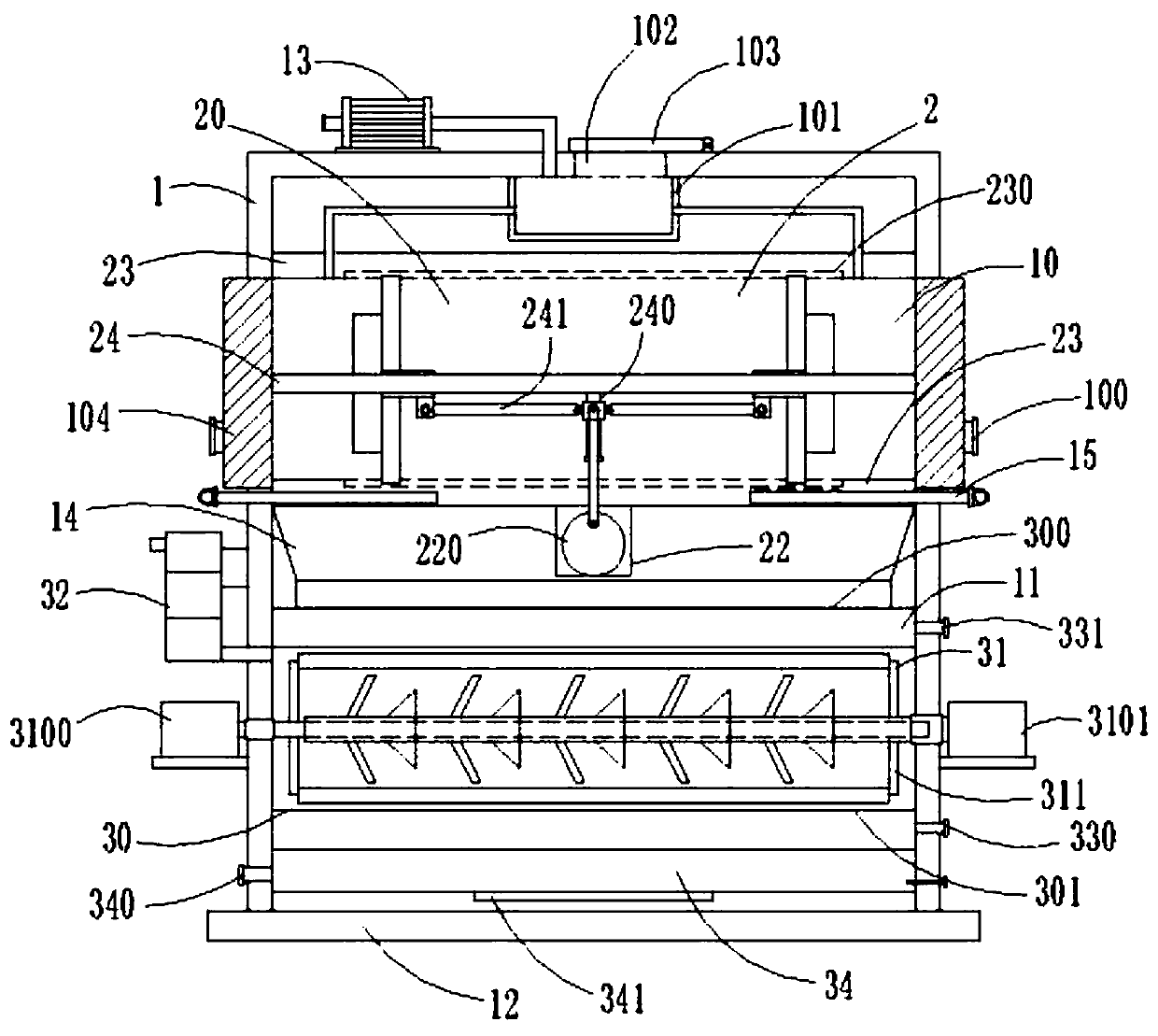

[0020] Example: such as figure 1 , 3 A municipal sludge recycling treatment device shown includes a device shell 1, a sludge dewatering component 2 and a pyrolysis component 3; a dehydration chamber 10 and a pyrolysis chamber 11 are sequentially arranged in the device shell 1 from top to bottom, A base 12 is provided at the bottom of the device housing 1, and a sludge pump 13 is provided on the device housing 1. The dehydration chamber 10 and the pyrolysis chamber 11 are connected by a mud guide bucket 14, and at the junction of the dehydration chamber 10 and the mud guide bucket 14 A movable plate 15 is provided, and a drain port 100 is provided at the lower side of the dehydration chamber 10. The dehydration chamber 10 is connected to the sludge pump 13 through a conduit; the upper end of the dehydration chamber 10 is provided with a sludge pretreatment frame 101, and the sludge pump 13 is connected to the sludge pretreatment frame 101 and then connected to the dehydration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com