A road base construction method in high temperature season with cement-stabilized gravel mixture

A technology for cement-stabilized crushed stone and road base, which is applied to roads, roads, cement mixing devices, etc., can solve the problems of insufficient effective construction time of cement-stabilized crushed stone mixture, and achieve sufficient construction delay time, sufficient construction time, and guarantee. The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

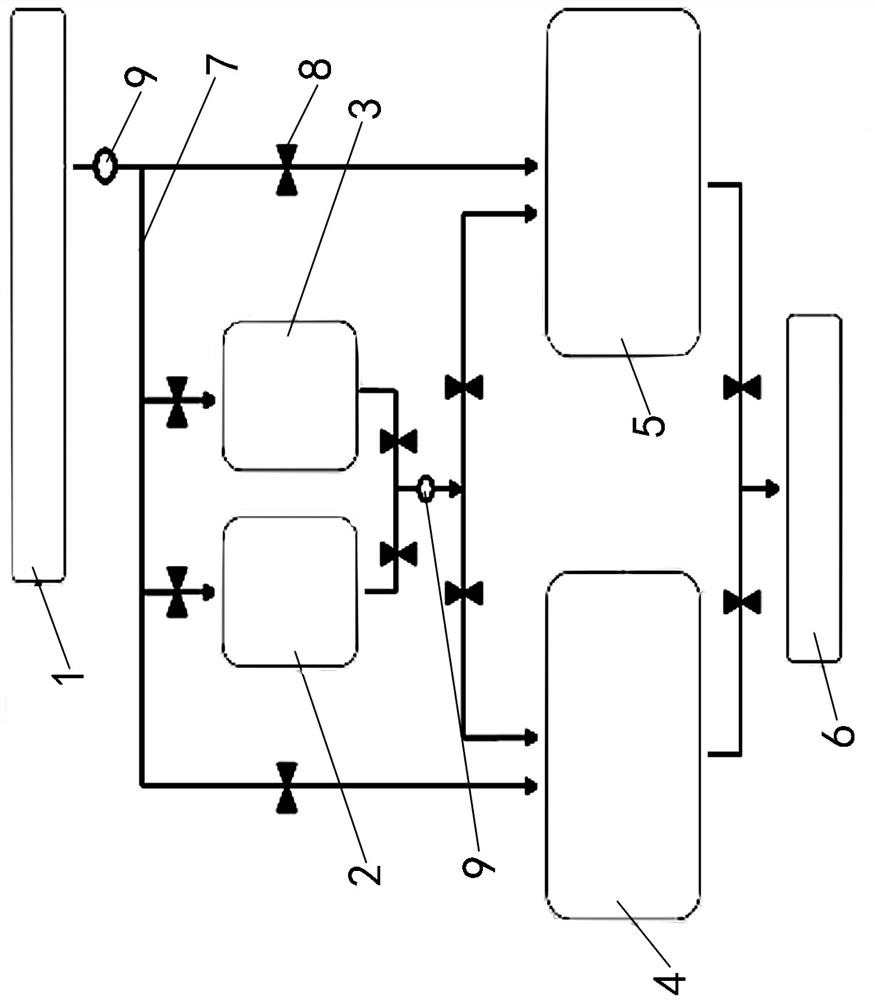

Image

Examples

Embodiment

[0053] A cement-stabilized crushed stone mixture comprising cement, sucrose solution, stabilized crushed stone coarse aggregate and fine aggregate,

[0054] Its component mass ratio is as follows:

[0055] Cement: 3%-5%;

[0056] Stabilized gravel coarse aggregate: 60%-65%;

[0057] Fine aggregate: 35%-40%;

[0058] The rest is sucrose solution.

[0059] This method of road base construction in high temperature season using cement-stabilized gravel mixture, the construction steps are as follows:

[0060] Step 1, mix ratio design of cement-stabilized gravel mixture:

[0061] Adjust according to the results of on-site sampling and screening, among which:

[0062] The gradation of the aggregate is close to the aggregate gradation curve of the indoor mix ratio design, and the deviation range of the sieve hole is controlled within ±3%;

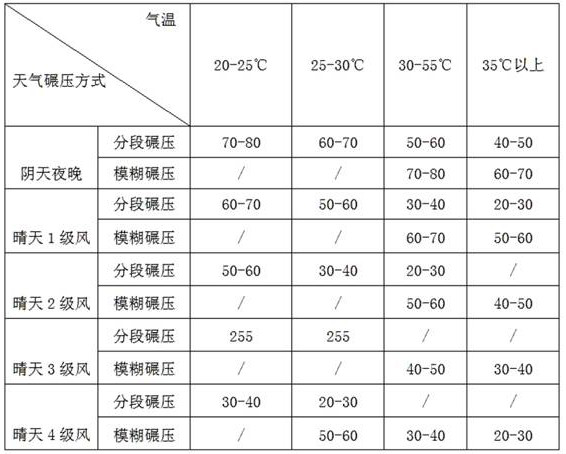

[0063] According to the on-site construction temperature, determine the cement quality, water quality and the amount of sucrose in the water t...

Embodiment 1

[0097] Embodiment 1: The cement stabilized crushed stone mixture is composed of the following mass percentage components, cement: 5%, sucrose: 0.1‰ (accounting for cement); stabilized crushed stone coarse aggregate: 60%-65%, fine aggregate: 35% -40%.

Embodiment 2

[0098] Embodiment 2: The cement stabilized crushed stone mixture is composed of the following mass percentage components, cement: 4.5%, sucrose: 0.2‰ (accounting for cement); stabilized crushed stone coarse aggregate: 60%-65%, fine aggregate: 35% -40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com