Mechanical and electromagnetic response synchronous test system and method for dynamic fracture of brittle material

A brittle material and synchronous testing technology, applied in the direction of analyzing materials, electromagnetic field characteristics, measuring devices, etc., can solve the problems of limited testing accuracy and inability to accurately study the characteristics of brittle materials, and achieve the effect of solving triggers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

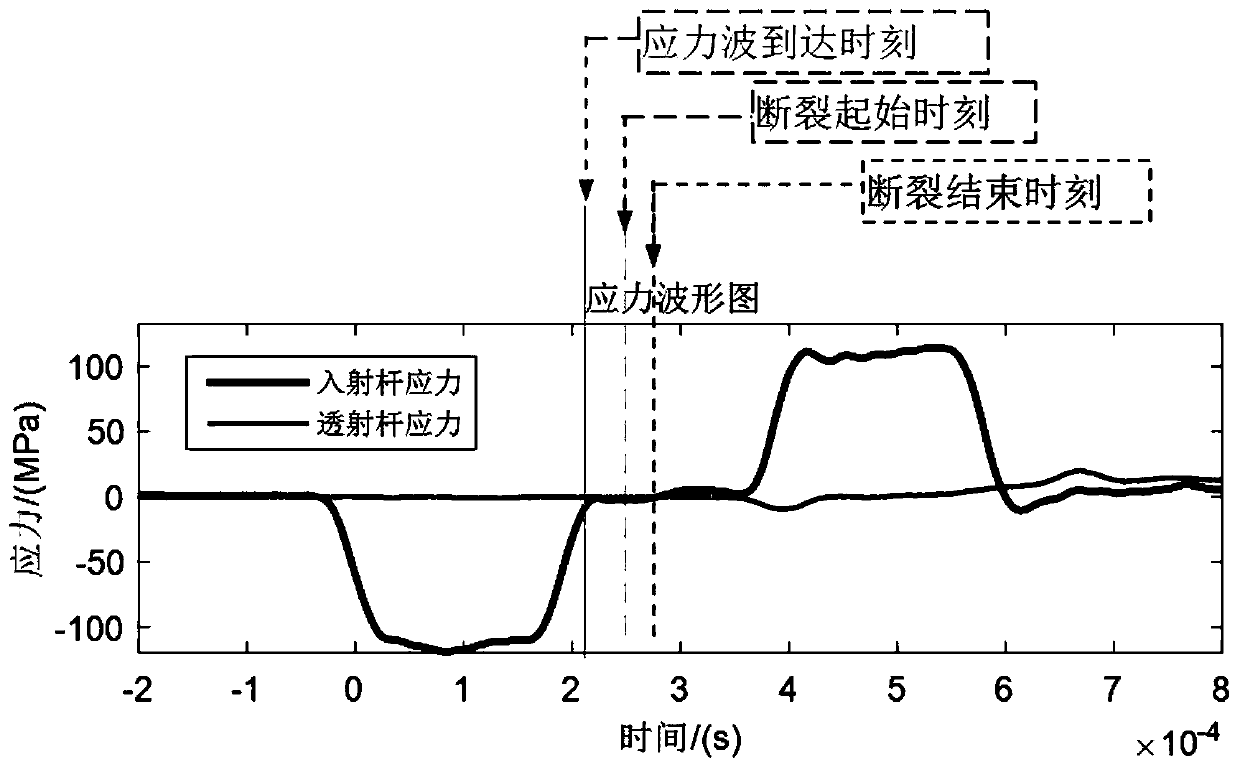

[0039] Specifically taking the dynamic Brazilian disc experiment of granite as an example, the present invention will be further described in conjunction with the accompanying drawings.

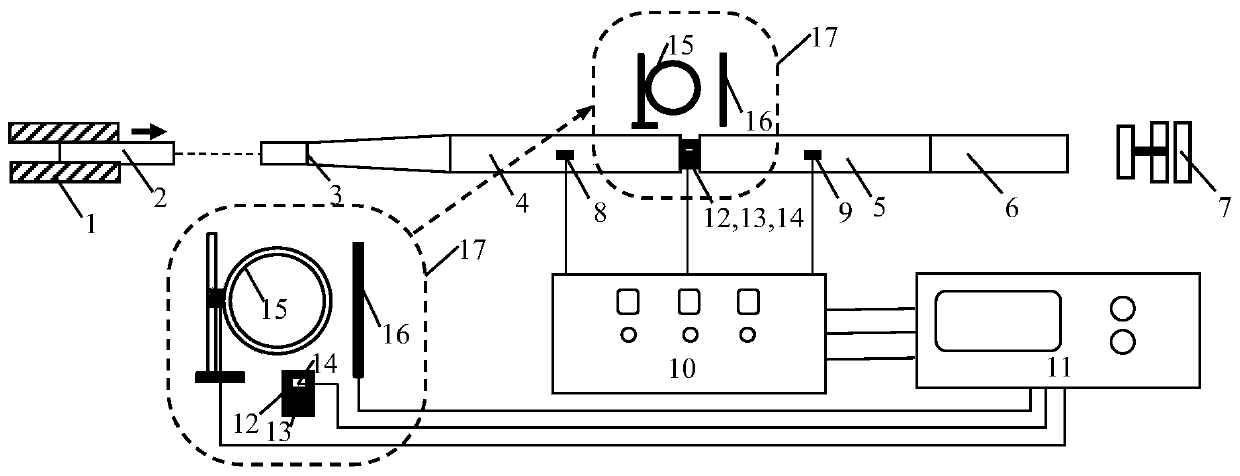

[0040] Such as figure 1 As shown, a simultaneous testing system of mechanical and electromagnetic responses for dynamic fracture of brittle materials, including a Hopkinson rod loading subsystem, a load displacement testing subsystem, a sample subsystem, an antenna testing subsystem and an electromagnetic shielding subsystem;

[0041] The Hopkinson rod loading subsystem includes a barrel body 1, an impact rod 2, a variable section rod 3, an incident rod 4, a transmission rod 5, an absorption rod 6 and a damper 7 arranged concentrically from left to right;

[0042] The load displacement testing subsystem includes an incident rod strain gauge 8, a transmission rod strain gauge 9, an ultra-dynamic strain gauge 10 and a high-performance oscilloscope 11;

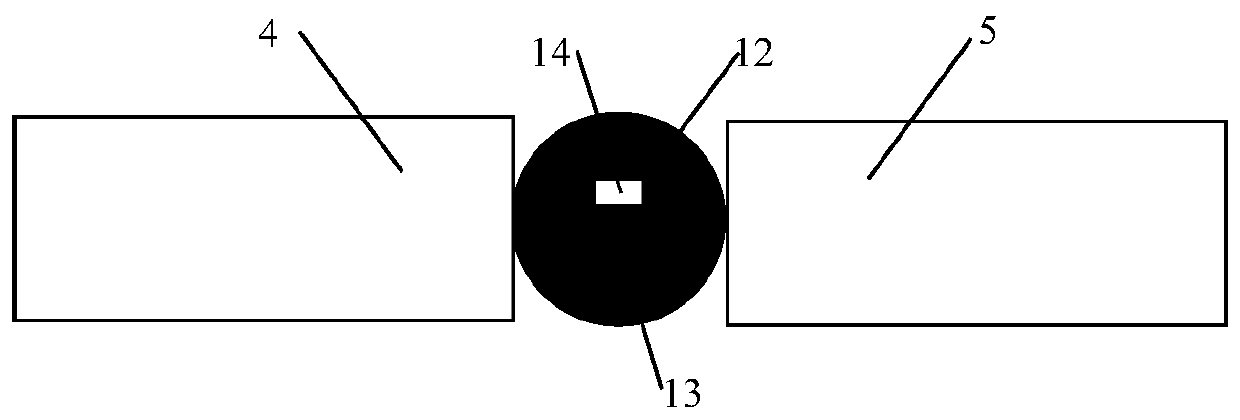

[0043] The sample subsystem includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com