Electroless nickel immersion gold surface treatment method for polyphenyl ether-containing printed circuit board

A printed circuit board, chemical nickel gold technology, applied in the field of chemical nickel gold surface treatment of polyphenylene ether-containing printed circuit boards, can solve the problems of chemical nickel gold whitening and degolding, reduce precipitates, and reduce gold staining effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

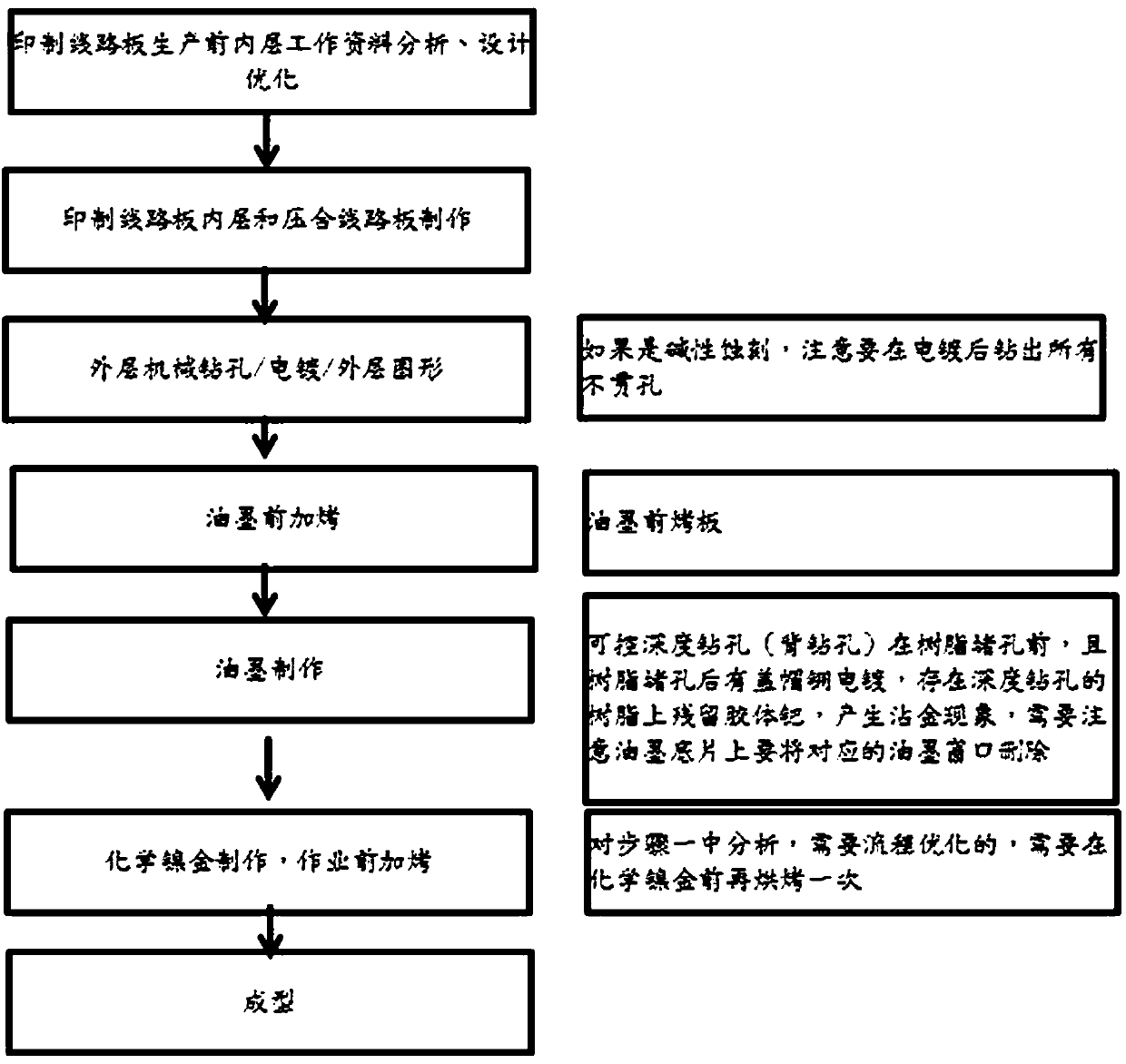

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0033] Such as figure 1 Shown, a kind of method that contains polyphenylene ether printed circuit board chemical nickel-gold surface treatment, comprises

[0034] a. Data analysis and optimization design of the inner layer of the circuit board;

[0035] b. Print the inner layer of the printed circuit board and press the circuit board;

[0036] c. Mechanical drilling of the outer layer of the circuit board, copper electroplating and outer graphic production;

[0037] d. Execute the baking process;

[0038] e. Ink production;

[0039] f. Execute the baking process;

[0040] g. Carry out chemical nickel-gold treatment.

[0041] Inner layer data analysis and design optimization before printed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com