A heating control device and method for a paper-making reconstituted tobacco drying box

A technology for reconstituted tobacco leaves and heating control, which is applied in the fields of tobacco, tobacco processing, application, etc. It can solve problems such as unstable control, unsafe operation of steam pipe accessories and post-stage equipment, and unstable product quality control, so as to save manpower. , Avoid long response time, reduce the effect of operating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

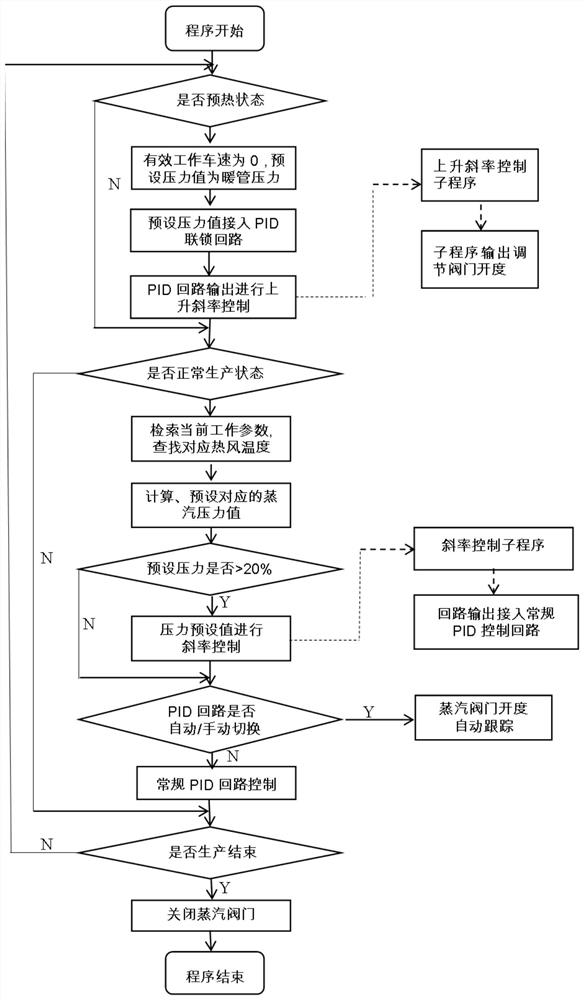

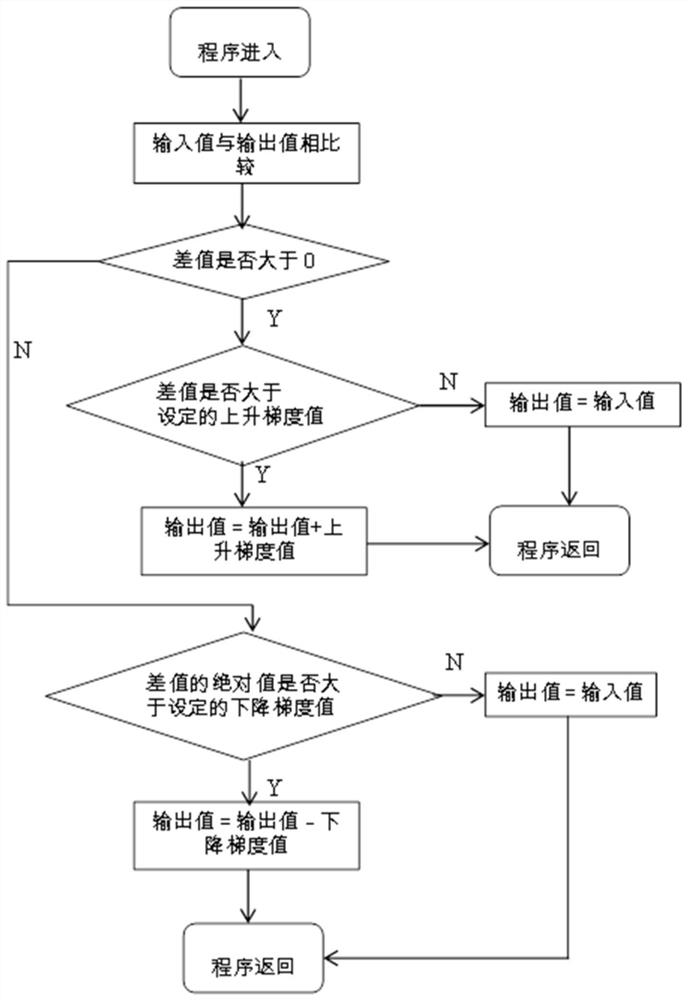

[0041] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

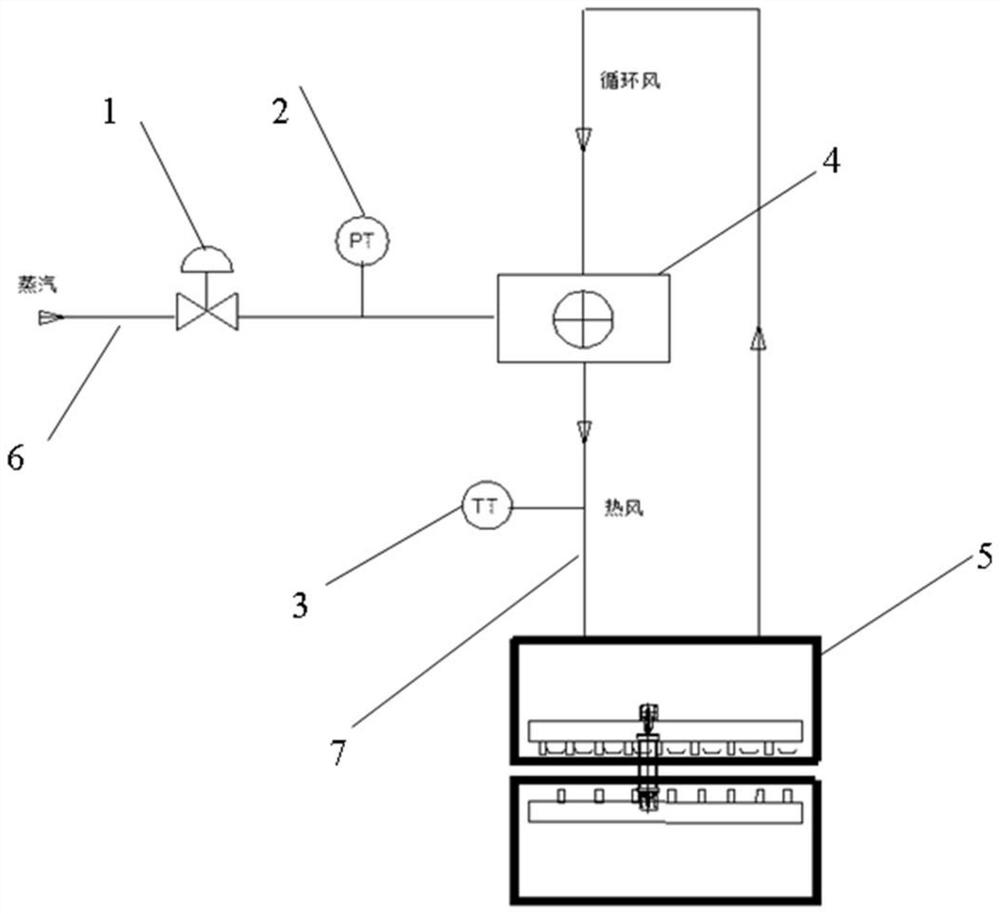

[0042] like figure 1 As shown, the heating control device of the papermaking method reconstituted tobacco leaf drying box provided by the present application includes a heat exchanger 4, a steam valve 1, a pressure gauge 2, a hot air drying box 5, a temperature gauge 3, a steam pipeline 6 and a hot blast pipeline 7, and the heat The heating side of the exchanger is a steam pipeline. One end of the steam pipeline is connected to fresh saturated steam, and the other end is connected to the heating side inlet of the heat exchanger. Steam valves and pressure gauges are installed on the steam pipeline before entering the heat exchanger. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com