Casting processing equipment and processing technology

A technology for processing equipment and castings, applied in the field of casting processing equipment and processing technology, can solve the problems of slow cooling speed of castings and reduced casting efficiency, and achieve the effects of improving cooling efficiency, ensuring cooling speed and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

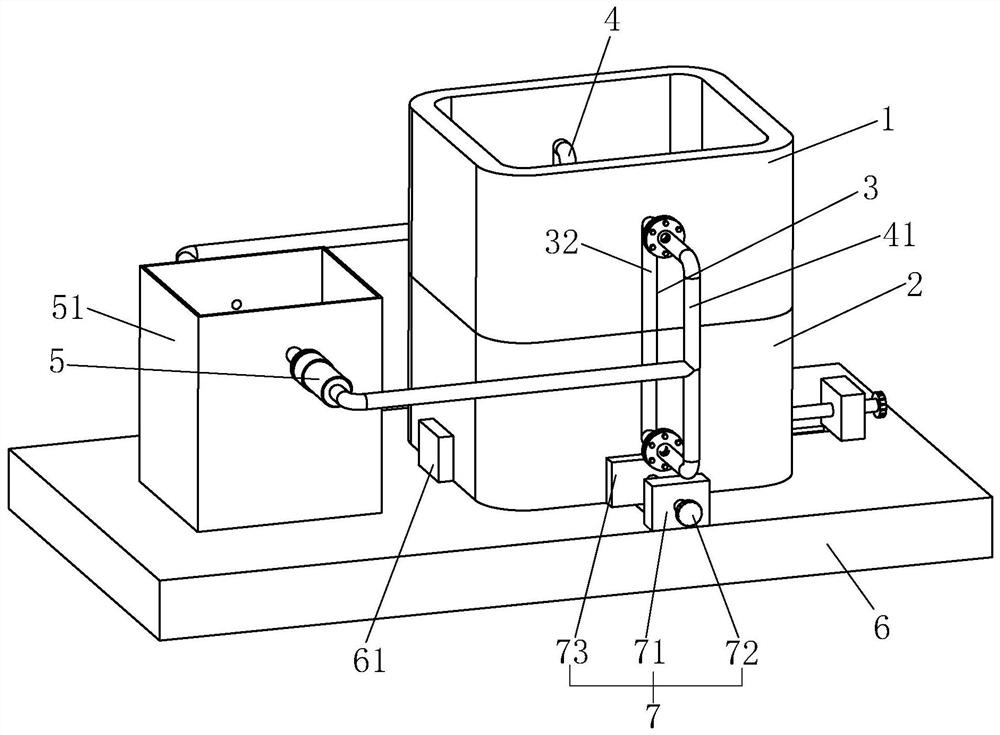

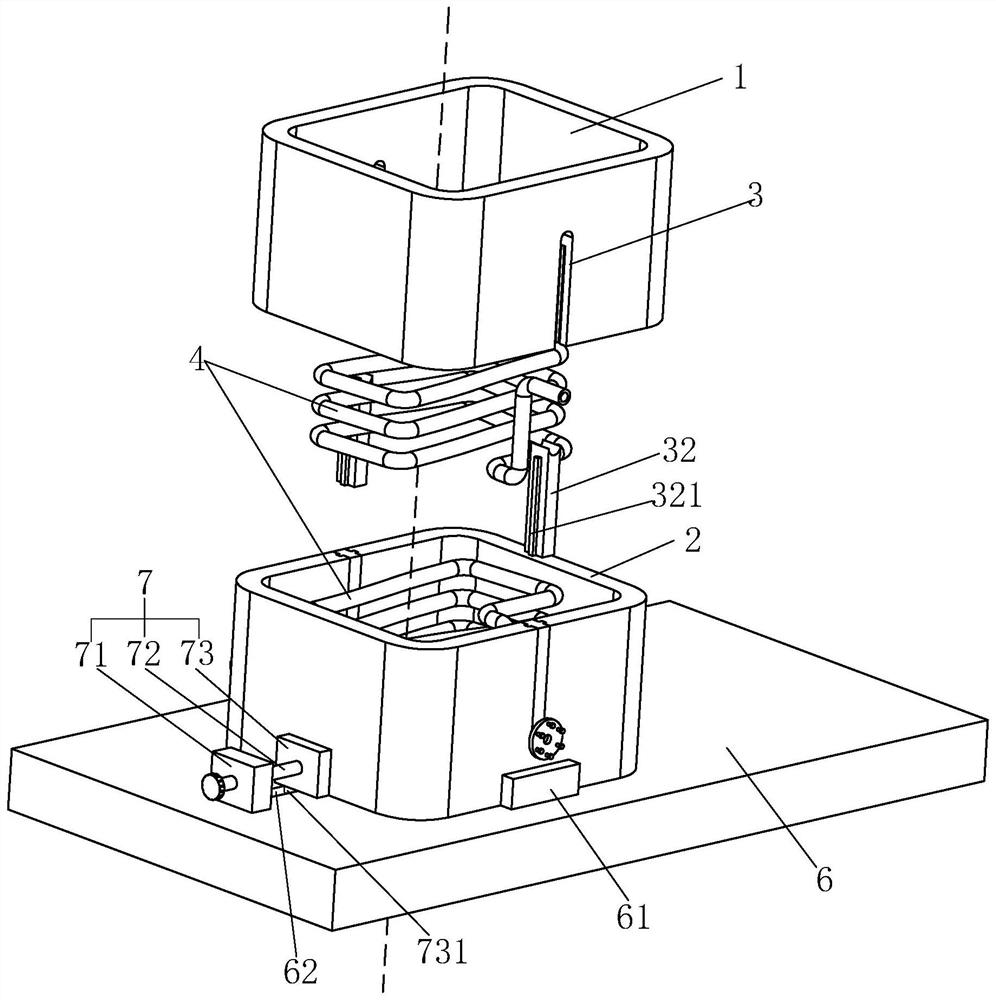

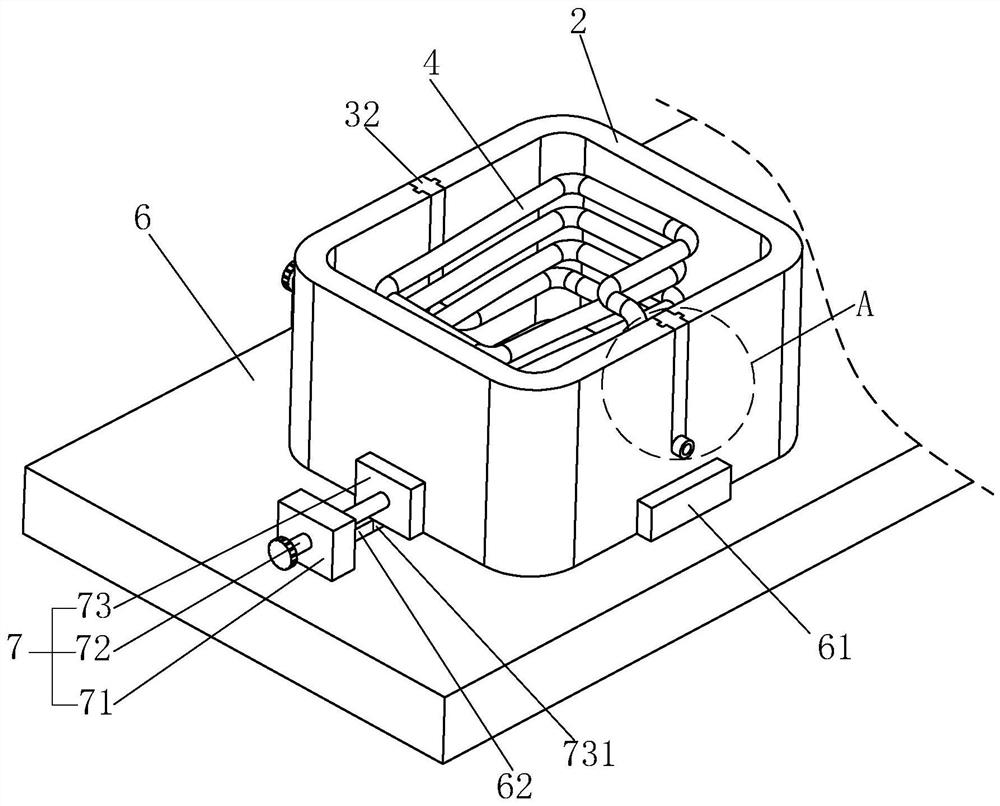

[0037] A casting processing equipment, such as figure 1As shown, including the upper shell type 1 and the lower shell type 2 stacked up and down, the upper shell type 1 and the lower shell type 2 are both vertically connected, and the bottom of the lower shell type 2 is placed with a horizontal bottom plate 6. During casting, Fill the area surrounded by the upper shell mold 1 and the lower shell mold 2 with the molding sand, and cover the mold with the molding sand. After compacting the molding sand, open the sprue and air passage on the top of the molding sand, and then separate the upper shell mold 1 and the lower shell Type 2, the mold cavity is formed after the mold is taken out, and the casting is cast by the runner to form the casting. The upper shell type 1 and the lower shell type 2 are equipped with cooling components around the cavity to accelerate the cooling of the casting, thereby improving the quality of the casting. manufacturing efficiency.

[0038] Such as ...

Embodiment 2

[0046] A casting process, comprising the steps of:

[0047] S1. Configure molding sand. The molding sand is made by mixing raw sand, clay, water, vegetable oil and sawdust, and the mixing ratios of raw sand, clay, water, vegetable oil and sawdust are 73%, 10%, 8%, 4%, and 5%, respectively. %;

[0048] S2. Install the lower shell type 2, contact the two sides of the lower shell type 2 with the reference plate 61, turn the lead screw 72, and the lead screw 72 drives the clamping plate 73 to abut against the outer surface of the lower shell type 2;

[0049] S3. Fill one-third of the molding sand into the lower shell type 2, then put the mold prefabricated in advance into the lower shell type 2, and put the cooling pipe 4 into the lower shell type 2, so that the mold is located in the cooling pipe 4 In the annular area of the shell, continue to fill the molding sand in the lower shell type 2 until it is filled;

[0050] S4. Stack the upper shell type 1 on the top of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com