Hippurate anti-corrosion ionic liquid and its preparation method and application

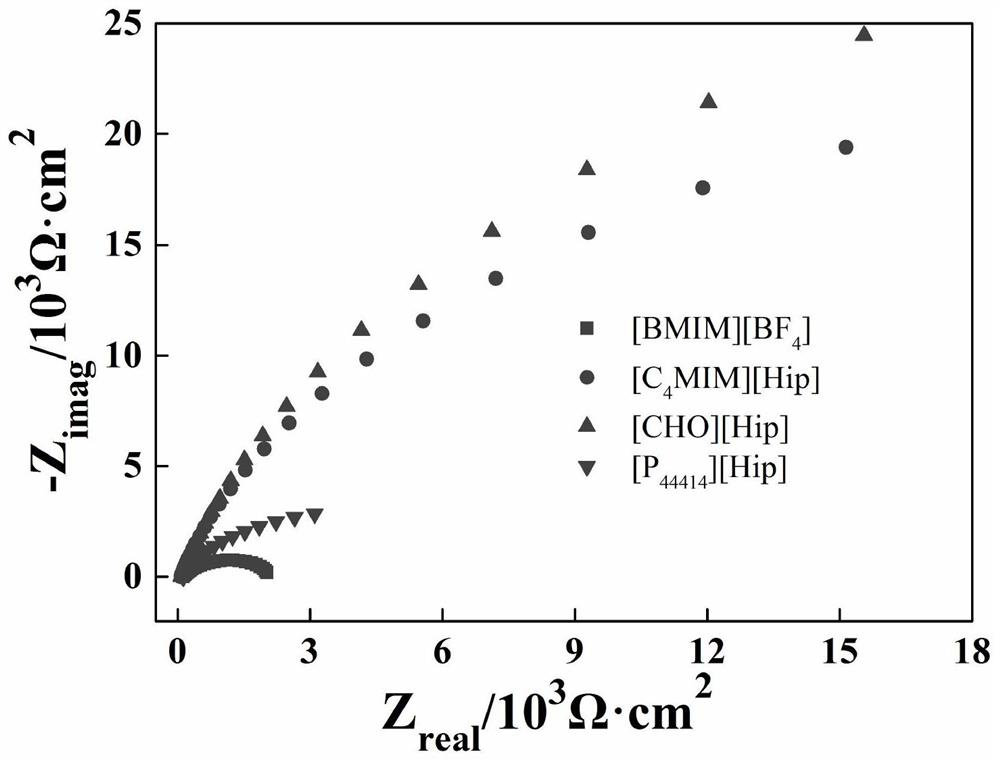

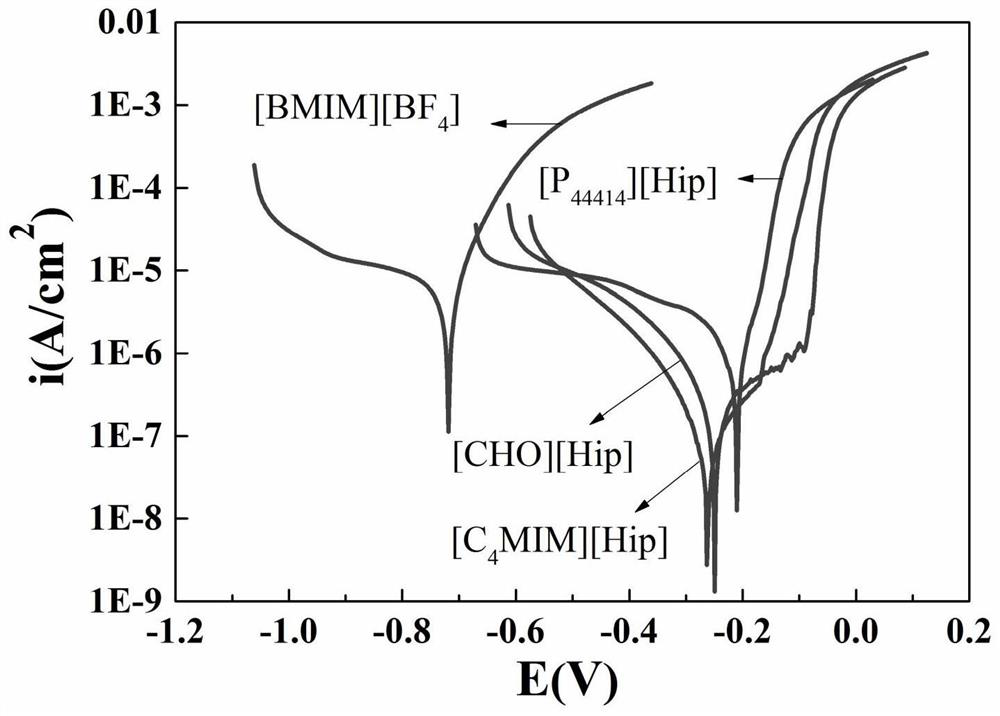

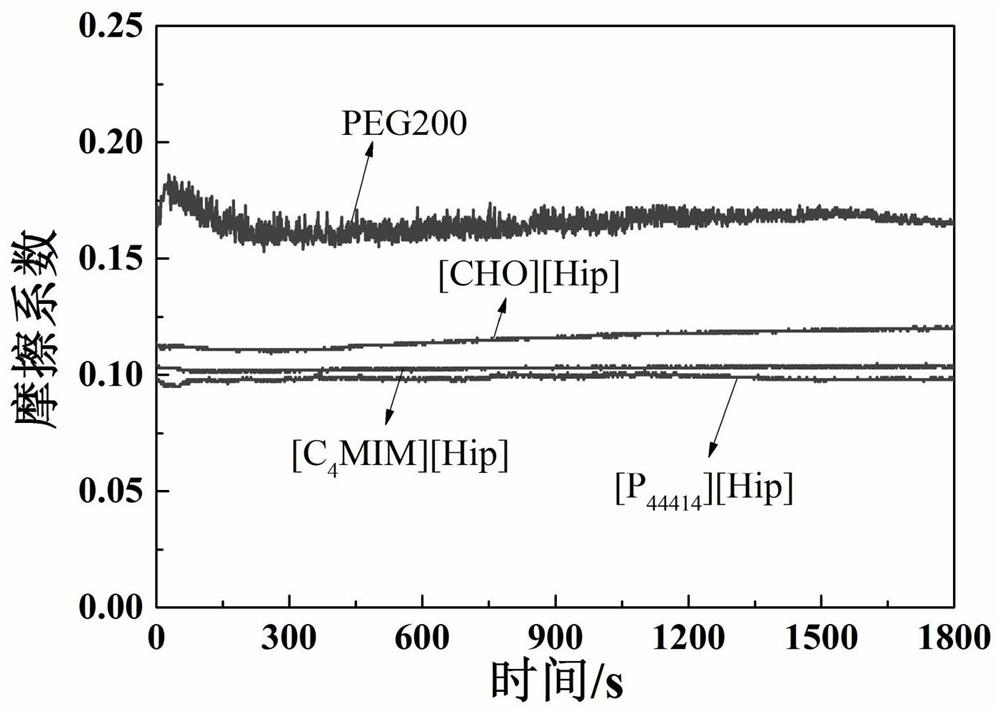

A technology of hippurate and corrosion resistance, which is applied in the field of hippurate anti-corrosion ionic liquid and its preparation, can solve problems such as strong corrosion, and achieve the effect of good corrosion resistance and excellent lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 24.14g sodium hippurate and 20.38g silver nitrate into 50mL distilled water respectively to prepare sodium hippurate aqueous solution and silver nitrate aqueous solution, the mol ratio of sodium hippurate and silver nitrate is 1:1.0, utilize constant pressure funnel then Add dropwise into sodium hippurate aqueous solution, stir at room temperature for 30 minutes, then filter to collect the precipitate, and wash the precipitate with 150ml of 50% ethanol aqueous solution for 3 times to obtain silver hippurate solid. 14.66g of methyl ethyl imidazolium chloride ionic liquid was dissolved in distilled water to prepare aqueous chloride solution, wherein the mol ratio of methyl ethyl imidazolium chloride ionic liquid to silver hippurate was 1:1.2, and then added to the chloride solution Silver hippurate was solid, stirred and reacted at room temperature for 5 hours, filtered to remove the precipitate to obtain the filtrate, and the filtrate was rotary evaporated and th...

Embodiment 2

[0029] Dissolve 24.14g sodium hippurate and 20.38g silver nitrate into 50mL distilled water respectively to prepare sodium hippurate aqueous solution and silver nitrate aqueous solution, the mol ratio of sodium hippurate and silver nitrate is 1:1.0, utilize constant pressure funnel then Add dropwise into sodium hippurate aqueous solution, stir at room temperature for 30 minutes, then filter to collect the precipitate, and wash the precipitate with 150ml of 50% ethanol aqueous solution for 3 times to obtain silver hippurate solid. 17.47g methyl butyl imidazolium chloride ionic liquid was dissolved in distilled water to prepare aqueous chloride solution, the mol ratio of methyl butyl imidazole chloride to silver hippurate was 1:1.2, then hippuric acid was added to the aqueous chloride solution Silver solid, stirred and reacted at room temperature for 8 hours, filtered to remove the precipitate to obtain the filtrate, and the filtrate was rotary evaporated and then dried in a vacu...

Embodiment 3

[0033] Dissolve 24.14g sodium hippurate and 20.38g silver nitrate into 50mL distilled water respectively to prepare sodium hippurate aqueous solution and silver nitrate aqueous solution, the mol ratio of sodium hippurate and silver nitrate is 1:1.0, utilize constant pressure funnel then Add dropwise into sodium hippurate aqueous solution, stir at room temperature for 30 minutes, then filter to collect the precipitate, and wash the precipitate with 150ml of 50% ethanol aqueous solution for 3 times to obtain silver hippurate solid. 20.27g methylhexylimidazole chloride ionic liquid is dissolved in distilled water to obtain chloride solution, wherein the mol ratio of methylhexylimidazole chloride and silver hippurate is 1:1.2, and then silver hippurate is added in the chloride solution, Stir the reaction at room temperature for 10 hours, remove the precipitate by filtration to obtain the filtrate, and then dry the filtrate in a vacuum oven at 80°C for 36 hours to obtain a hippurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com