A method and product for extracting al-ce tubular intermetallic compound from magnesium alloy

A technology of intermetallic compounds and magnesium alloys, which is applied in the field of extraction of Al-Ce tubular intermetallic compounds, can solve the problems of low superconducting transition temperature, complex cooling equipment, inability to guarantee the morphology and purity of intermetallic compounds, and achieve extraction rate High and quick response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

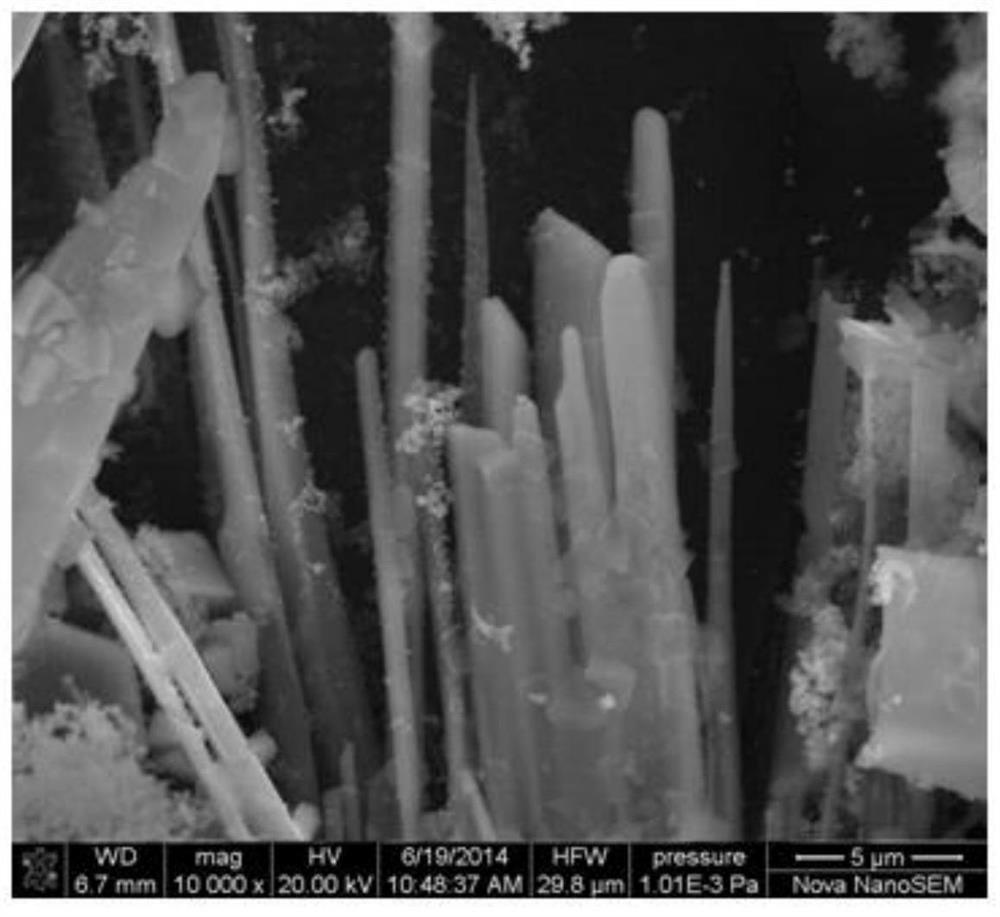

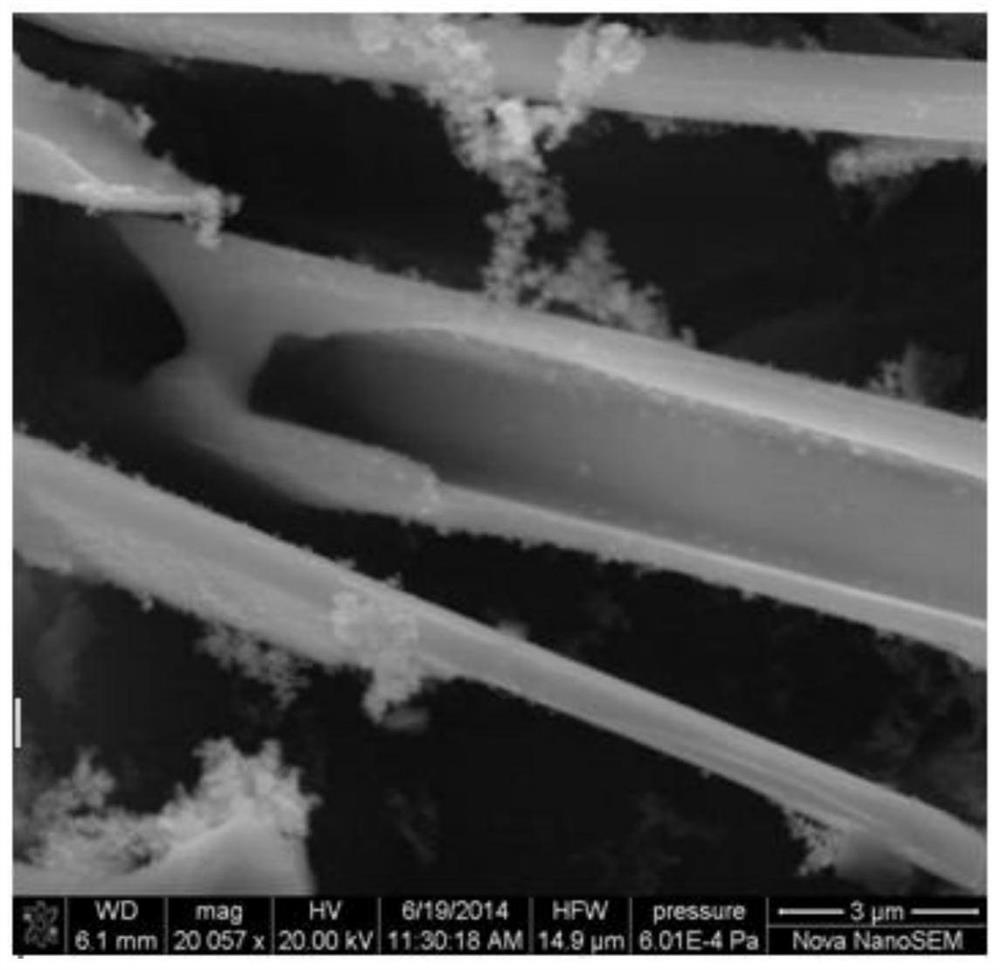

[0037] Extraction of Al-Ce Tubular Intermetallic Compounds

[0038] (1) Prepare a magnesium alloy containing Al-Ce tubular intermetallic compound, the magnesium alloy is composed of the following components in terms of mass percentage: Al: 7.9%, Zn: 0.6%, Mn: 0.5%, Sn: 2.0%, Ce: 2.0%, unavoidable impurities ≤ 0.1%, the balance is magnesium, the preparation method is as follows:

[0039] Using pure magnesium ingots, pure aluminum ingots, pure zinc ingots, pure tin ingots, Mg-5%Mn master alloys and Mg-20%Ce master alloys as raw materials, according to the above-mentioned composition of magnesium alloys containing Al-Ce tubular intermetallic compounds Calculate the batching by mass percentage, turn on the smelting furnace, and when the temperature of the furnace reaches 370°C, pass the protective gas (CO 2 +0.5% SF 6 ), then add pure magnesium ingots, pure aluminum ingots, Mg-Mn master alloys and Mg-Ce master alloys preheated to 150°C into the melting furnace, and heat up to 68...

Embodiment 2

[0045] Extraction of Al-Ce Tubular Intermetallic Compounds

[0046] (1) Prepare a magnesium alloy containing Al-Ce tubular intermetallic compound, the magnesium alloy is composed of the following components in terms of mass percentage: Al: 8.5%, Zn: 0.2%, Mn: 0.3%, Sn: 2.0%, Ce: 2.0%, unavoidable impurities ≤ 0.1%, the balance is magnesium, the preparation method is as follows:

[0047] Using pure magnesium ingots, pure aluminum ingots, pure zinc ingots, pure tin ingots, Mg-5%Mn master alloys and Mg-20%Ce master alloys as raw materials, according to the above-mentioned composition of magnesium alloys containing Al-Ce tubular intermetallic compounds Calculate the batching by mass percentage, turn on the melting furnace, and when the temperature of the furnace reaches 350°C, pass the protective gas (CO 2 +0.5% SF 6 ), then add pure magnesium ingots, pure aluminum ingots, Mg-Mn master alloys and Mg-Ce master alloys preheated to 155°C into the melting furnace, and heat up to 675...

Embodiment 3

[0053] Extraction of Al-Ce Tubular Intermetallic Compounds

[0054] (1) Prepare a magnesium alloy containing Al-Ce tubular intermetallic compound, which is composed of the following components in terms of mass percentage: Al: 9.2%, Zn: 0.8%, Mn: 0.15%, Sn: 2.0%, Ce: 2.0%, unavoidable impurities ≤ 0.1%, the balance is magnesium, the preparation method is as follows:

[0055] Using pure magnesium ingots, pure aluminum ingots, pure zinc ingots, pure tin ingots, Mg-5%Mn master alloys and Mg-20%Ce master alloys as raw materials, according to the above-mentioned composition of magnesium alloys containing Al-Ce tubular intermetallic compounds Calculate the batching by mass percentage, turn on the smelting furnace, and when the temperature of the furnace reaches 400°C, pass the protective gas (CO 2 +0.5% SF 6 ), then add pure magnesium ingots, pure aluminum ingots, Mg-Mn master alloys and Mg-Ce master alloys preheated to 145°C into the melting furnace, and heat up to 685°C until pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com