1180MPa-grade high-plasticity bainite complex phase steel plate for automobile and preparation method for 1180MPa-grade high-plasticity bainite complex phase steel plate

A high plasticity, bainite technology, applied in the field of automotive steel manufacturing, can solve the problems of difficult body structural parts, resistance spot welding performance decline, high alloy cost, etc., achieve stable production process, reduce alloy cost, and simplify production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a 1180MPa grade high-plasticity bainite composite steel plate for automobiles, specifically comprising the following steps:

[0045] 1) Converter smelting

[0046] Smelting through a converter to obtain molten steel that meets the following composition requirements in terms of weight percentage, C: 0.03% to 0.25%, Si: 0.05% to 0.5%, Mn: 0.5% to 4.5%, P≤0.10%, S≤ 0.05%, Nb: 0.01% to 0.04%, Ti: 0.01% to 0.04%, V: 0.01% to 0.15%, and alternative components (by weight percentage) include: Cr: 0.5% to 2.0%, Mo: 0.01 to 0.05%, Al: 0.05% ~ 1.50%, Cu: 0.05% ~ 2.0%, the balance is Fe and unavoidable impurities, and the molten steel temperature is between 1500 ~ 1650 ℃.

[0047] 2) Medium and thin slab continuous casting

[0048] The casting temperature is 1400-1530°C, and the thickness of the continuous casting slab is between 120-180mm.

[0049] 3) Hot continuous rolling

[0050] The furnace temperature of casting slab is between 400-750°C, the heatin...

Embodiment 1

[0061] Table 1-Table 5 respectively list the chemical composition of the steel in Example 1, the continuous casting and hot rolling process parameters of the steel, the process parameters of the cold rolling and continuous annealing of the steel, the mechanical properties of the steel and the proportions of each phase.

[0062] The chemical composition wt (%) of table 1 embodiment steel

[0063] Example C mn Si P S Al Nb V Ti Cr Mo Cu 1 0.18 2.0 1.5 0.001 0.005 0.15 0.01 0.13 0.01 0.2 - -

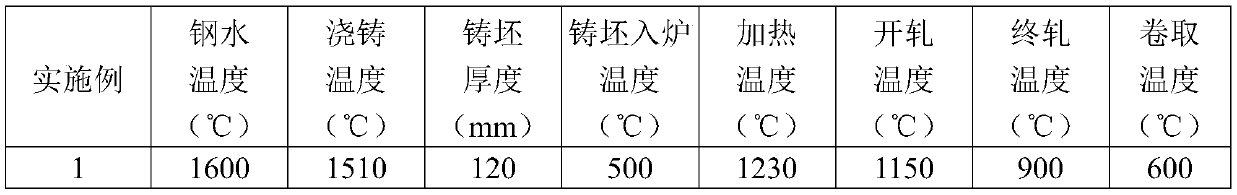

[0064] Continuous casting and hot rolling process of table 2 embodiment steel

[0065]

[0066] The cold rolling annealing process of table 3 embodiment steel

[0067]

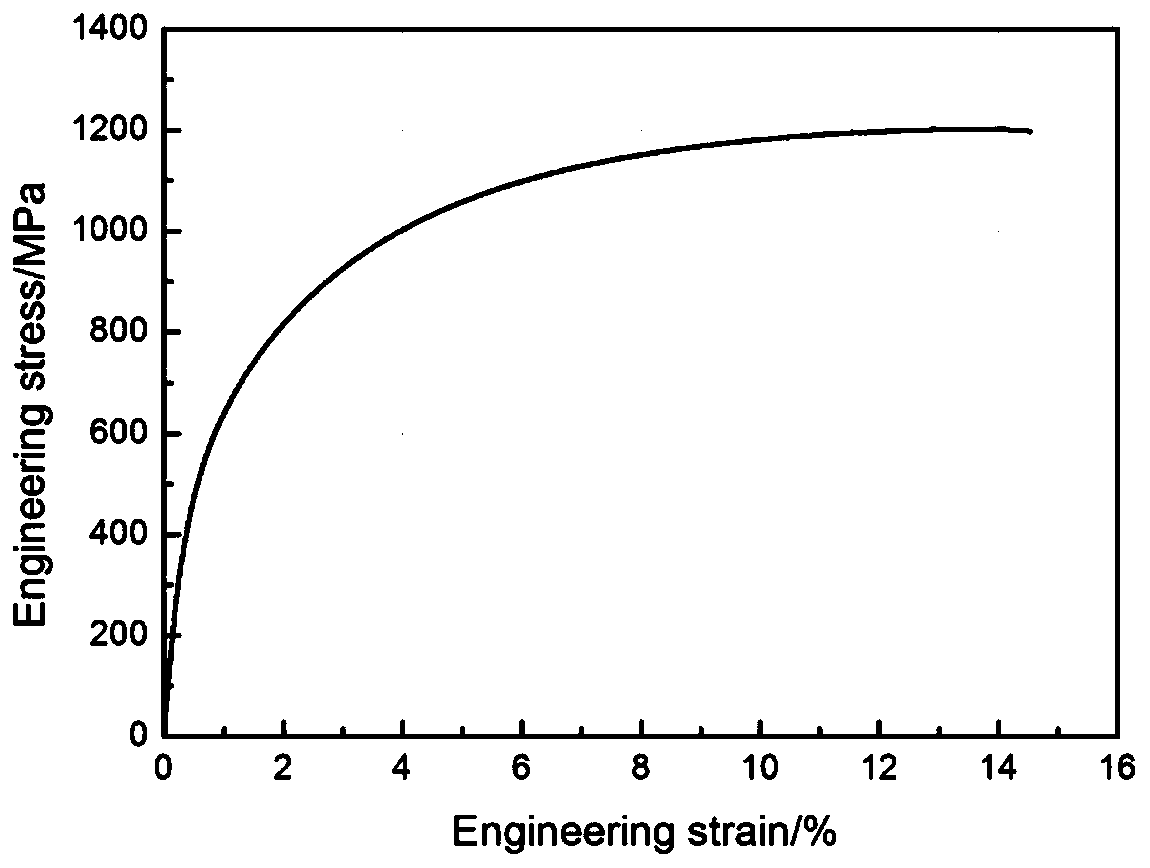

[0068] The mechanical property of table 4 embodiment steel

[0069] Example Rp 0.2 (MPa)

Rm(MPa) A 50 (%)

λ(%) 1 650 1181 16.2 30%

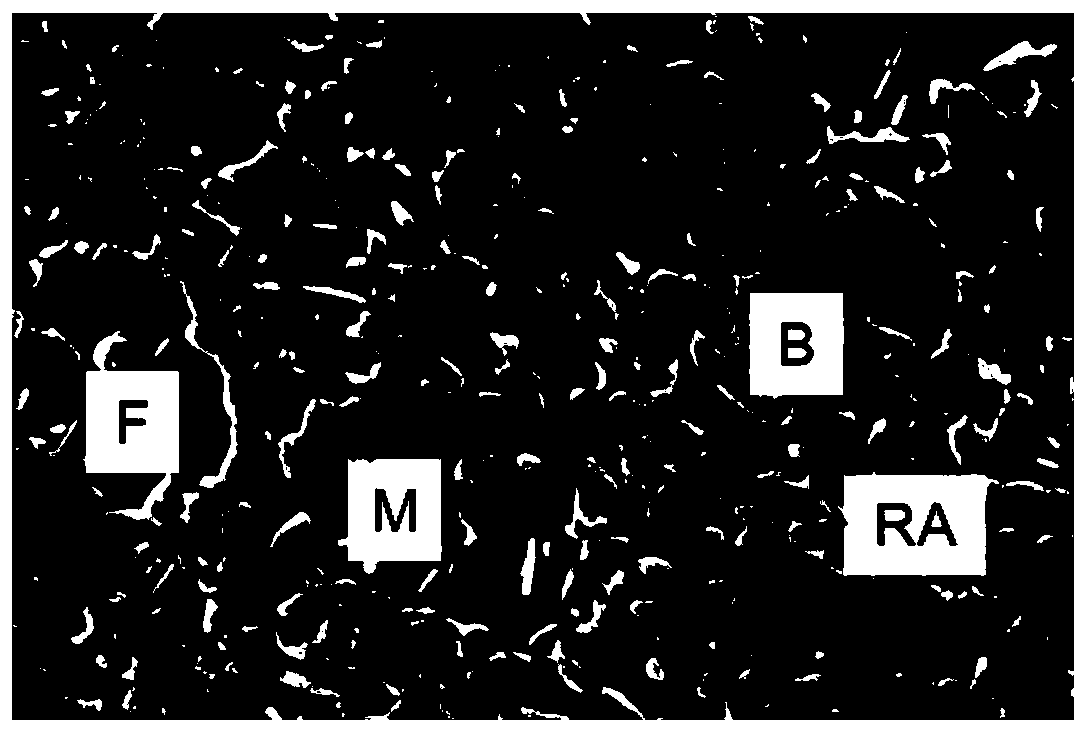

[0070] Each phase percentage vol.% of table 5 embodiment steel

[0071] Example ferrite...

Embodiment 2

[0073] Table 6-Table 10 respectively list the chemical composition of the steel in Example 2, the continuous casting and hot rolling process parameters of the steel, the process parameters of the cold rolling and continuous annealing of the steel, the mechanical properties of the steel and the proportions of each phase.

[0074] The chemical composition wt (%) of table 6 embodiment steel

[0075] Example C mn Si P S Al Nb V Ti Cr Mo Cu 2 0.17 2.1 1.3 0.002 0.005 0.30 0.01 0.10 0.02 0.1 - -

[0076] Continuous casting and hot rolling process of table 7 embodiment steel

[0077]

[0078] The cold rolling annealing process of table 8 embodiment steel

[0079]

[0080] The mechanical property of table 9 embodiment steel

[0081] Example Rp 0.2 (MPa)

Rm(MPa) A 50 (%)

λ(%) 2 702 1230 14.5 32%

[0082] Each phase percentage vol.% of steel of table 10 embodiment

[0083] Example fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com