Soft board structure, TO optical module and optical transmission device

An optical module and flexible board technology, applied in the field of optical communication, can solve the problems of small low-speed application of optical modules, deterioration of ultra-high-speed signal transmission, and inability to apply TO packaging, so as to improve impedance matching effect, reduce high-frequency noise, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

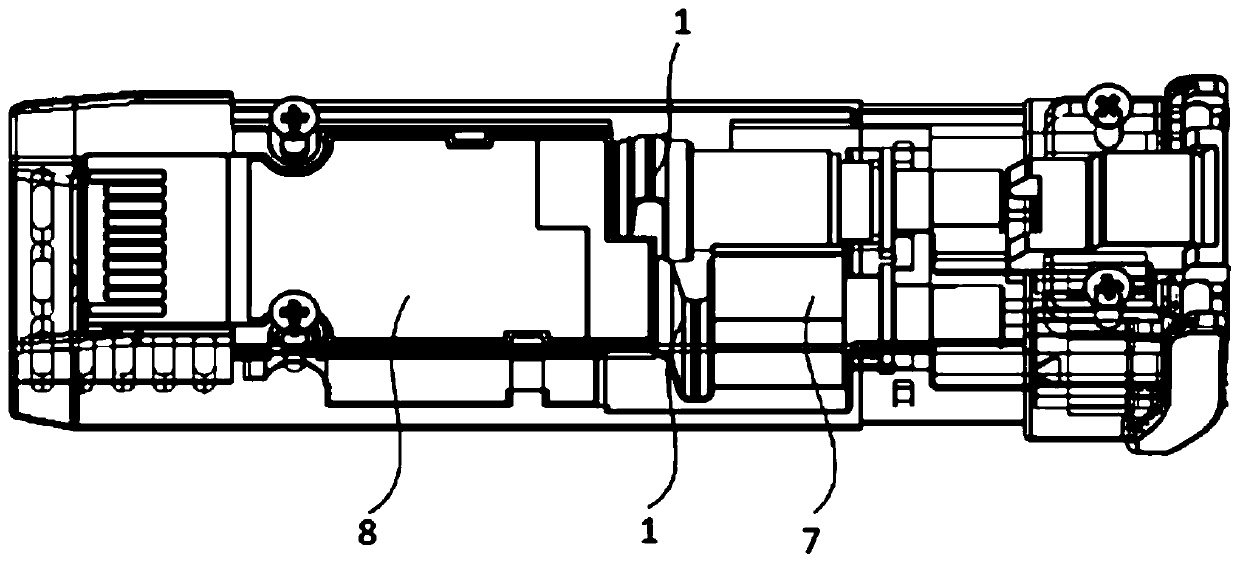

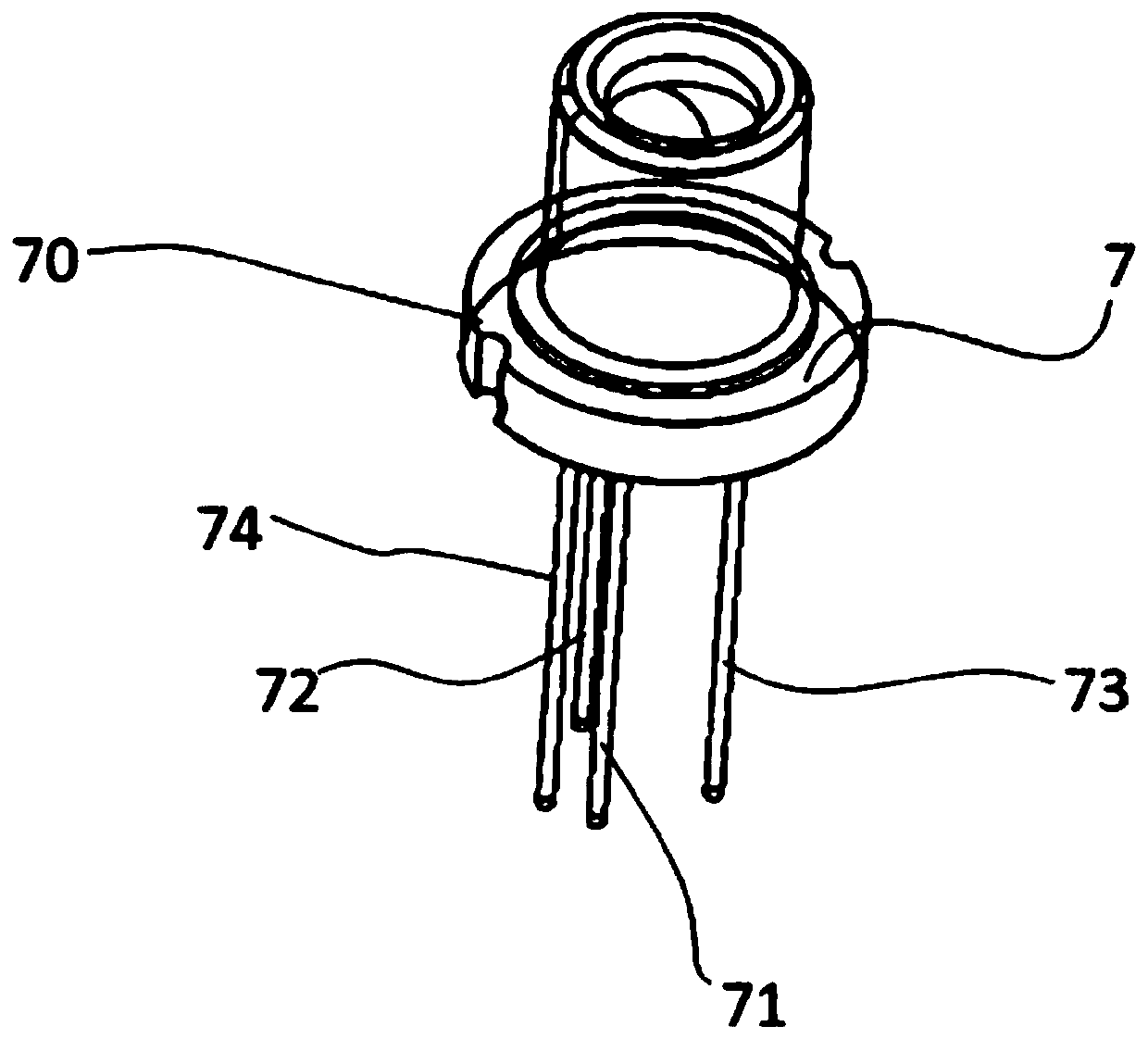

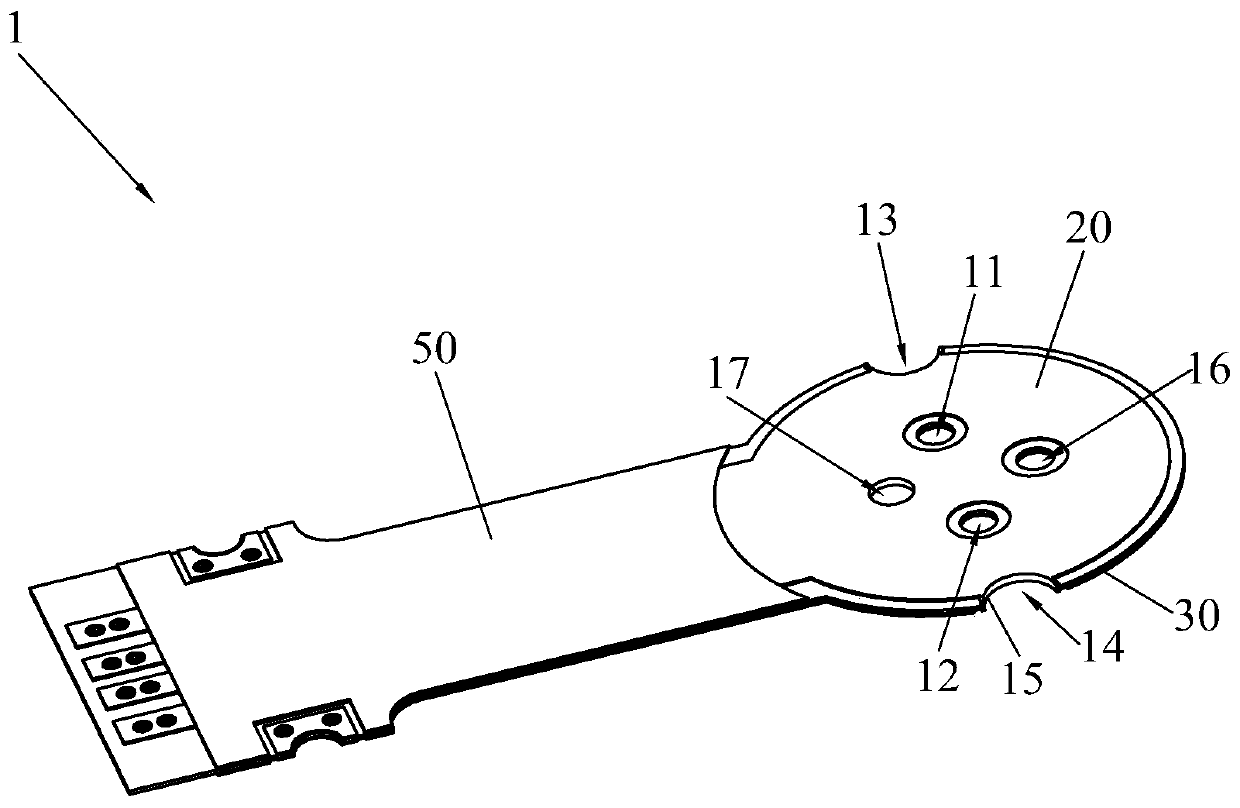

[0026] see Figure 1 to Figure 6 , the present invention discloses a flexible board structure 1 for connecting with a TO optical device 7. The flexible board structure 1 includes a first metal layer 20, a base material 30, and a second metal layer 40 stacked sequentially from bottom to top. The first The metal layer 20 is configured to provide a ground plane, the second metal layer 40 forms a high-speed signal link, and a first high-speed signal via hole 11 and a second high-speed signal via hole 12 are formed on the flexible board structure 1. A first port 13 and a second port 14 are respectively formed near the first high-speed signal via hole 11 and the second high-speed signal via hole 12, and the side walls of the first port 13 and the second port 14 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com