Intelligent low-temperature gas cooling safe monitoring temperature-regulating circulation system

A low-temperature gas, safety monitoring technology, used in control/regulation systems, temperature control, non-electric variable control, etc., can solve problems such as energy waste, environmental pollution, and frostbite for processing equipment operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in combination with specific embodiments.

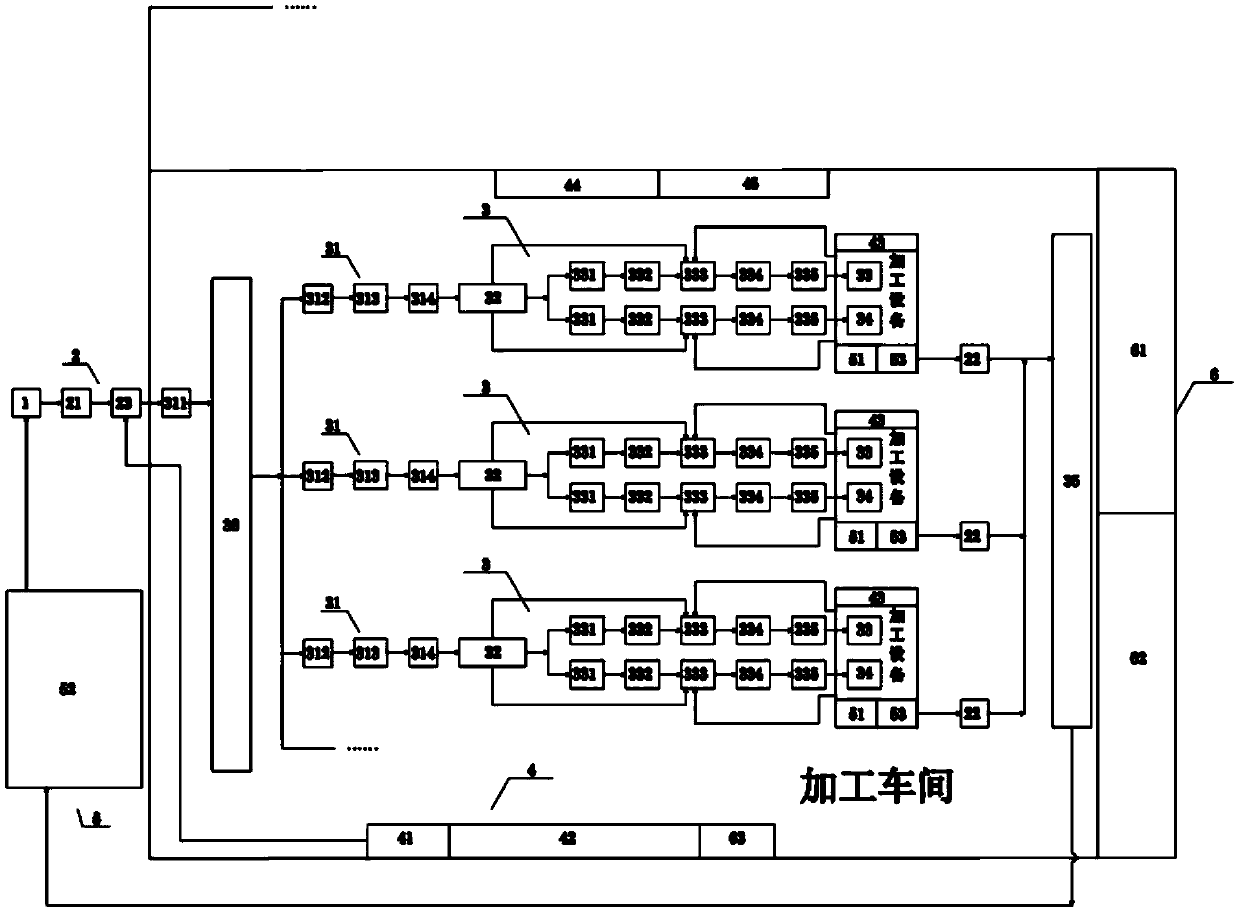

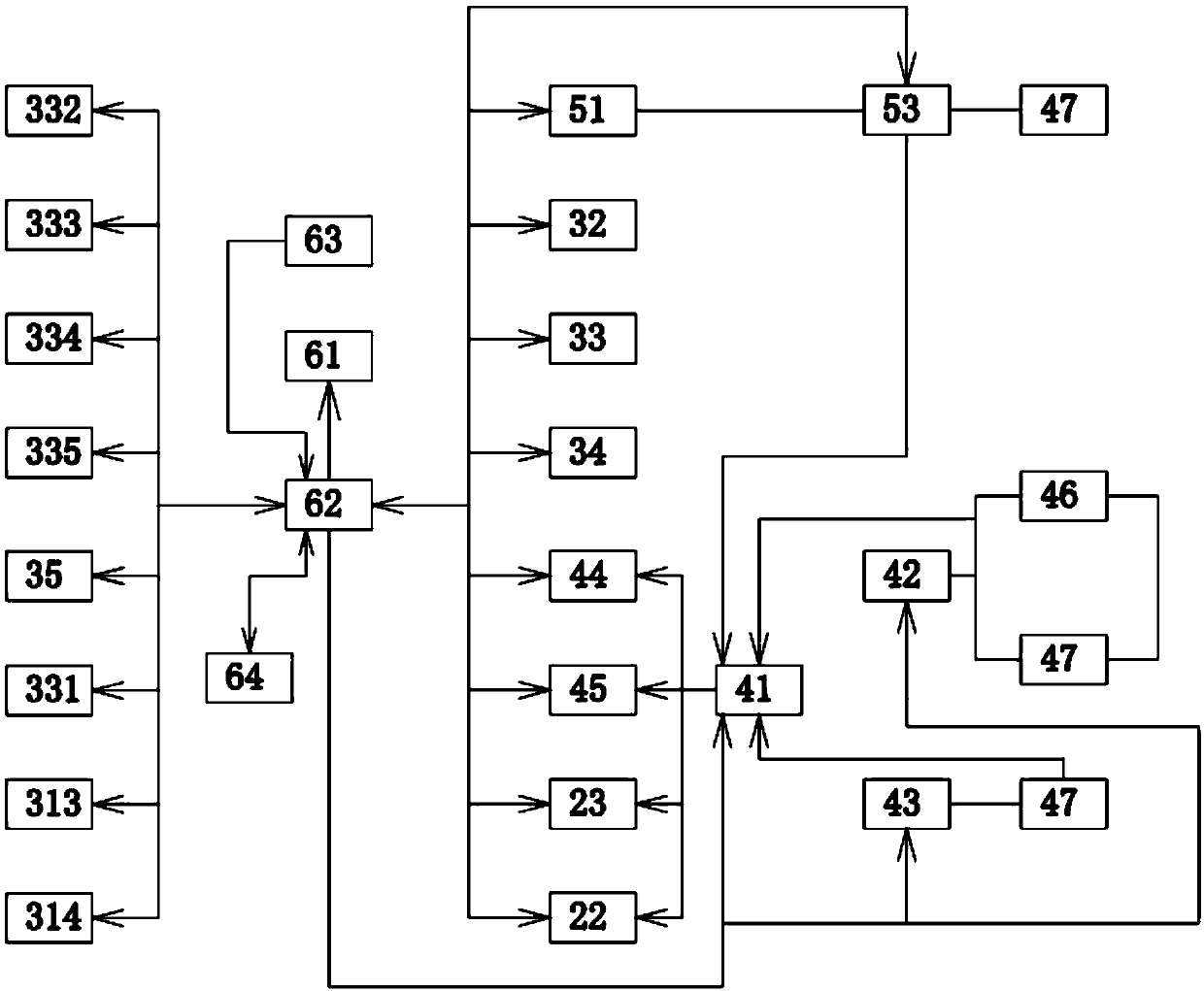

[0042] Such as figure 1 As shown, an intelligent low-temperature gas cooling safety monitoring and temperature-adjusting cycle system according to the present invention includes a low-temperature gas storage station 1, a first control device 2, several cooling systems 3, a safety monitoring device 4, a recycling device 5 and an intelligent low-temperature gas The safety monitoring side control system 6, the first control device 2, the safety monitoring device 4 are located in the cooling system 3 and control the first control device 2, the recycling recovery device 5 is connected to the cooling system 3, and the recycling recovery device 5 includes a cooling system located in the cooling system 3 The gas collection device 51 inside and the low-temperature gas gas production station 52 arranged outside the cooling system 3 , the low-temperature gas gas production station 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com