High-density wiring reset method

A reset method and high-density technology, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of sample failure, PAD pads can not be printed, deformation, etc., to improve the analysis speed and shorten the analysis. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

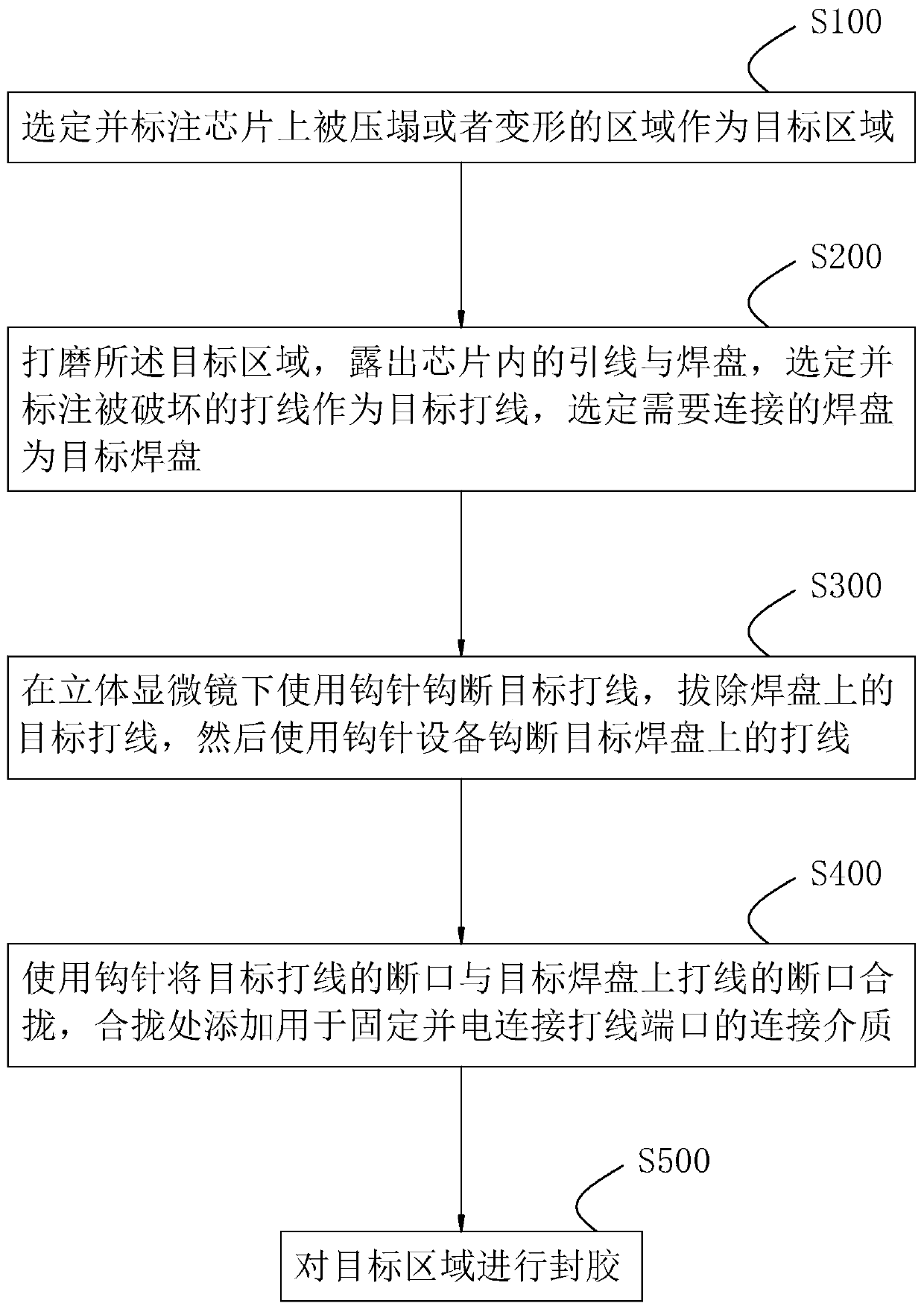

[0035] A high-density wiring reset method, such as figure 1 shown, including the following steps:

[0036] Step S100: Select and mark the crushed or deformed area on the chip as the target area. A pen can be used to draw a circle on the package of the chip.

[0037] Step S200: Polishing the target area to expose the leads and pads in the chip, selecting and marking the damaged bonding wires as the target bonding wires, and selecting the bonding pads to be connected as the target bonding pads. Use a grinder to grind the target area until the chip circuit in the package is exposed without damaging the internal circuit of the chip. Among them, the pads and wires are exposed. Target wires and target pads can be marked with a thin, colored pen.

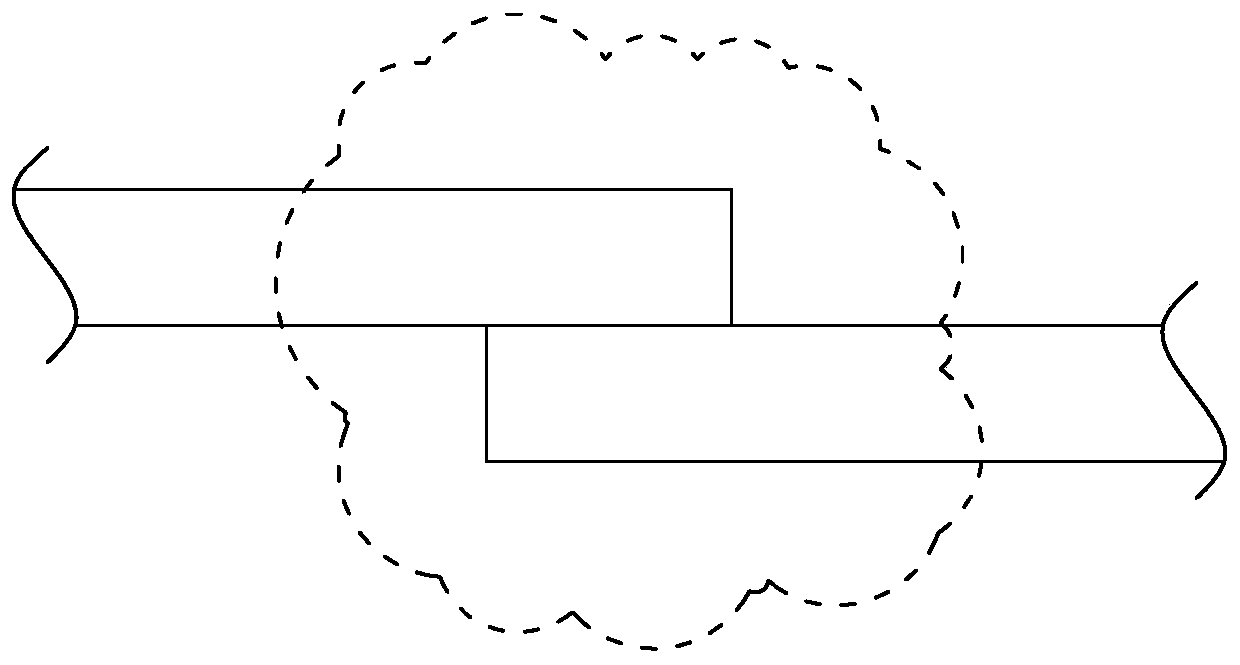

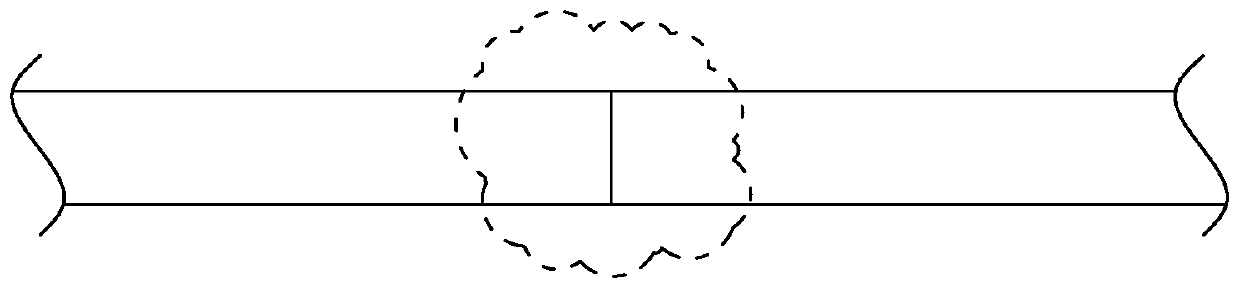

[0038] Step S300 : use a crochet hook to cut off the target bonding wire under a stereo microscope, pull out the target bonding wire on the pad, and then use a crochet device to hook off the target bonding wire on the pad. The inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com