Active starting circuit of Boost full-bridge isolation converter and method

A technology of isolating converters and starting circuits, which is applied in the direction of converting DC power input to DC power output, instruments, electrical components, etc., can solve the problems of large inrush current of input inductance, inability to release inductive energy, and breakdown of power switch tubes, etc. Achieve the effect of reducing current impact, reducing flyback winding design, and smooth start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

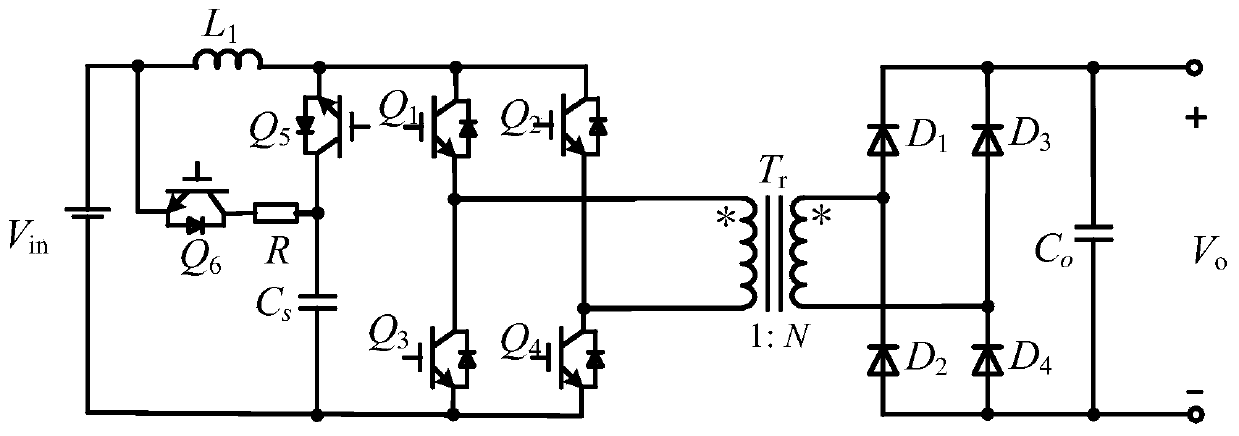

[0022] Such as figure 1 As shown, the present invention consists of an active switch Q6 and a resistor R to form a low-loss active start-up circuit; the present invention consists of a switching device Q5 and a clamping capacitor Cs to form an active clamping circuit, which is directly connected in parallel to the DC bus; the switching device Q1- Q4 forms a full-bridge power circuit, inductor L acts as a boost inductor, rectifier diodes D1-D4 form a high-frequency full-bridge rectifier circuit, and Co is an output filter capacitor.

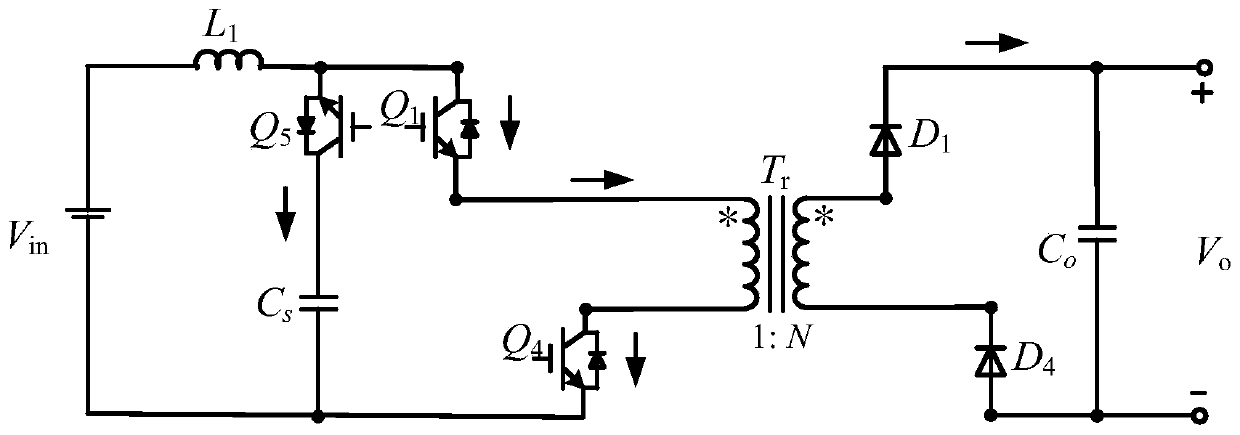

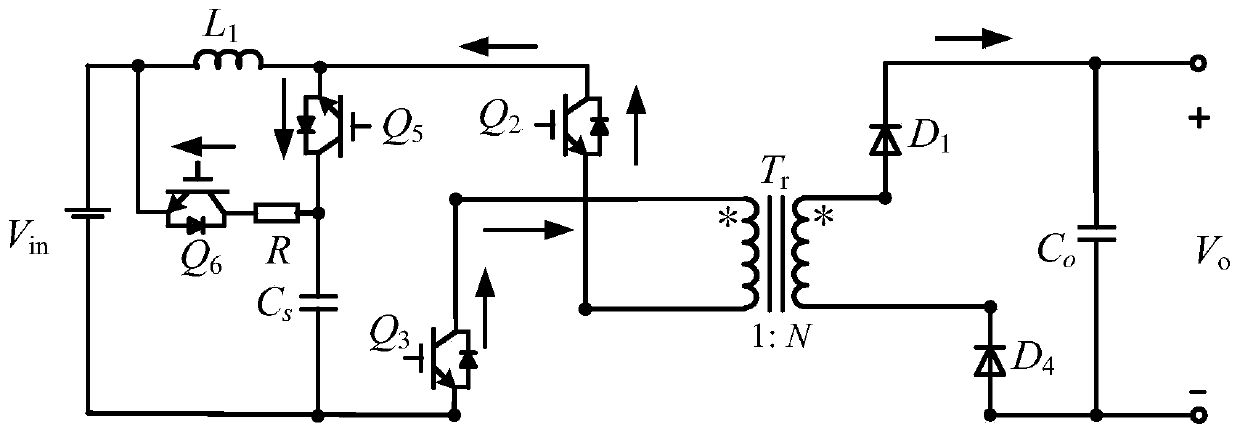

[0023] Such as Figure 4 As shown, the start-up process of the present invention has two working modes. Working mode 0 is that the switching devices Q1 and Q4 of the converter are turned on or Q2 and Q3 are turned on, and Q6 and Q5 are turned off. In this mode, the converter transmits to the secondary side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com