Electromagnetic heating electronic atomizer

An electronic atomizer and heater technology, applied in the field of electronic cigarettes, can solve the problems of large heat loss difference, short service life, poor heating effect, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

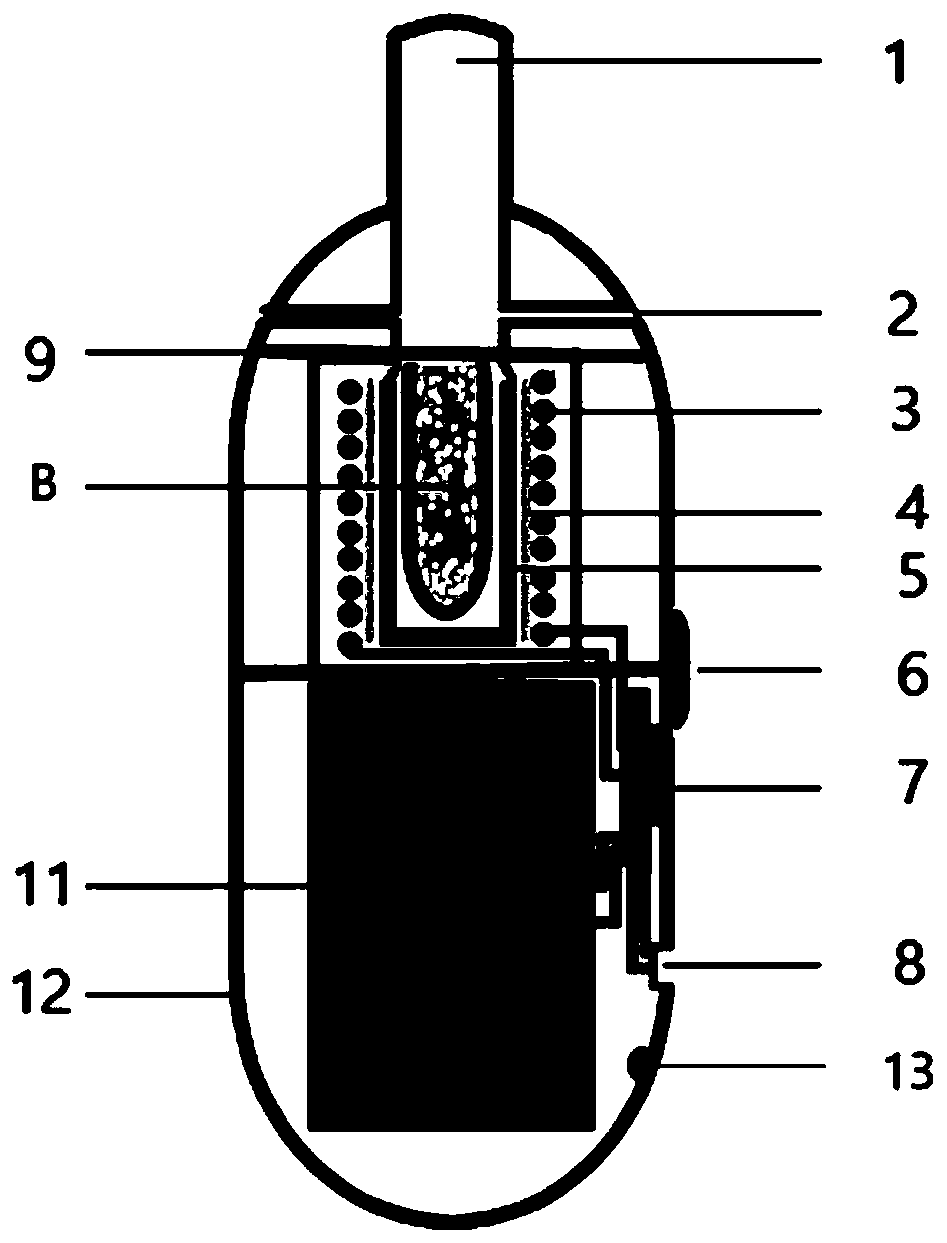

[0068] Embodiment 1: Magnetic heating electronic atomizer of the present invention

[0069] The implementation mode of this embodiment is as follows:

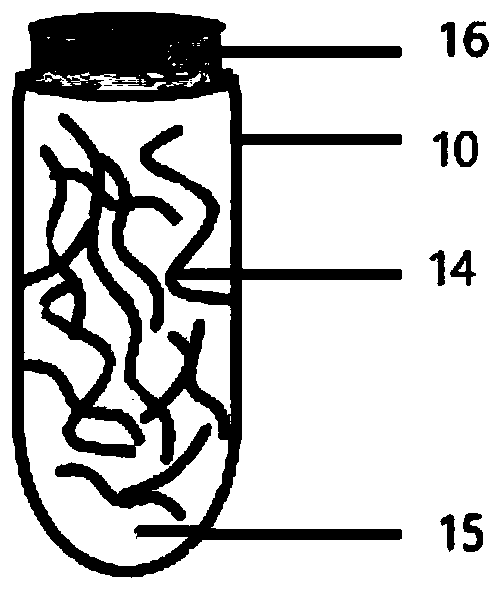

[0070]The magnetic heating electronic atomizer of the present invention is composed of a magnetic heater part A, a pod part B and an electronic atomizer shell 12;

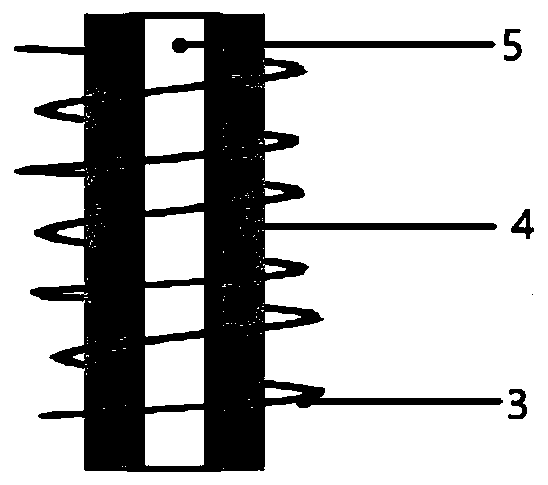

[0071] Magnetic heater part A consists of suction nozzle 1, flue gas channel 2, electromagnetic induction coil 3, heat insulation layer 4, heating chamber 5, electric switch 6, integrated circuit board 7, charging interface 8, medium and high frequency power supply 11 and indicator light 13 composition;

[0072] On the upper part of the electromagnetic heating electronic atomizer, the suction nozzle 1 communicates with the flue gas channel 2, and the suction nozzle 1 is connected to the top of the heating chamber 5 through the knob interface 9; a heat insulation layer 4 is arranged between the outer wall of the heating chamber 5 and the electromagnetic induction co...

Embodiment 2

[0083] Embodiment 2: Magnetic heating electronic atomizer of the present invention

[0084] The implementation of this embodiment is the same as that of Example 1, except that the electromagnetic induction coil 3 is a spiral copper coil sold by Shenzhen Xinhuiyuan Technology Co., Ltd. under the trade name open electromagnetic heating coil, and the resistivity is 1.75× 10 -8 Ω·m; the heating chamber 5 is made of materials sold by Shanghai Shuideng Industrial Co., Ltd. under the trade name of high-temperature and high-pressure special-shaped glass; two flue gas channels 2 with a diameter less than 2mm are arranged around the upper part of the heating chamber 5, and the heating chamber 5 The inner diameter of the glass is 5mm, the cavity wall thickness is 1mm, and the height is 10mm; it is made of a product sold by Shanghai Shuideng Industrial Co., Ltd. under the trade name high temperature and high pressure special-shaped glass. The heat insulation layer 4 is made of a product ...

Embodiment 3

[0087] Embodiment 3: Magnetic heating electronic atomizer of the present invention

[0088] The implementation of this embodiment is the same as that of Example 1, except that the electromagnetic induction coil 3 is two printed coils sold under the trade name High Precision PCB by Shenzhen Changdongxin Circuit Board Co., Ltd., and the resistivity is 1.45×10 -8 Ω·m, the magnetic field directions of these coils are all the same; the heating chamber 5 is made of ceramic materials sold by Dongguan Nuoyi Precision Ceramics Technology Co., Ltd. under the trade name zirconia ceramics; A flue gas channel 2 with a diameter less than 2mm; the inner diameter of the heating chamber 5 is 7mm, the thickness of the chamber wall is 4mm, and the height is 16mm; it is made of products sold by Dongguan Nuoyi Precision Ceramics Technology Co., Ltd. under the trade name zirconia ceramics . The heat insulation layer 4 is made of a product sold by Hebei Haowangda Thermal Insulation Building Materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com