A device for punching and forming materials by means of meshing and its application method

A stamping forming and meshing technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of many safety hazards, fast wear of extrusion dies, poor running stability, etc., and achieve low cost of use and low power consumption. Small, flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. In case of conflict, the definitions in this specification shall prevail. "Where a mass, concentration, density, temperature, time, or other value or parameter is expressed as a range, a preferred range, or a range bounded by a series of upper preferred values and lower preferred values, it is to be understood that it specifically discloses that any range upper limit or a preferred value with any pairing of any range lower limit or preferred value, whether or not that range is individually disclosed.

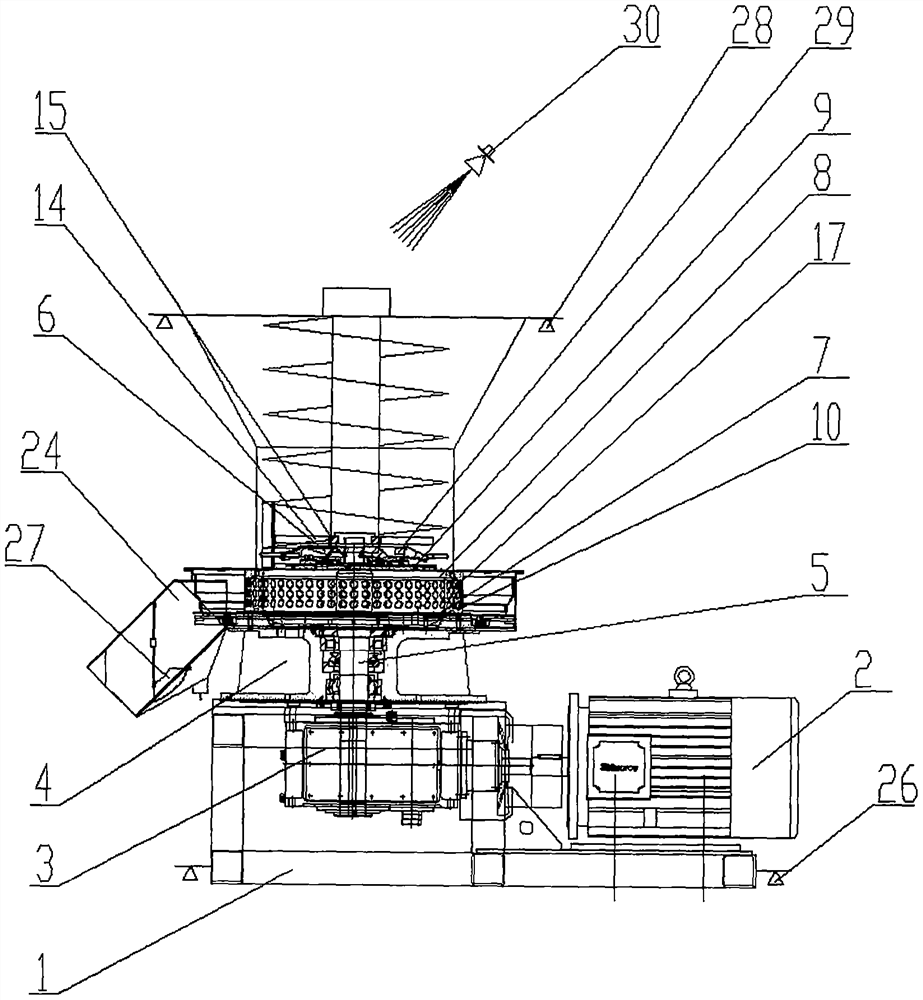

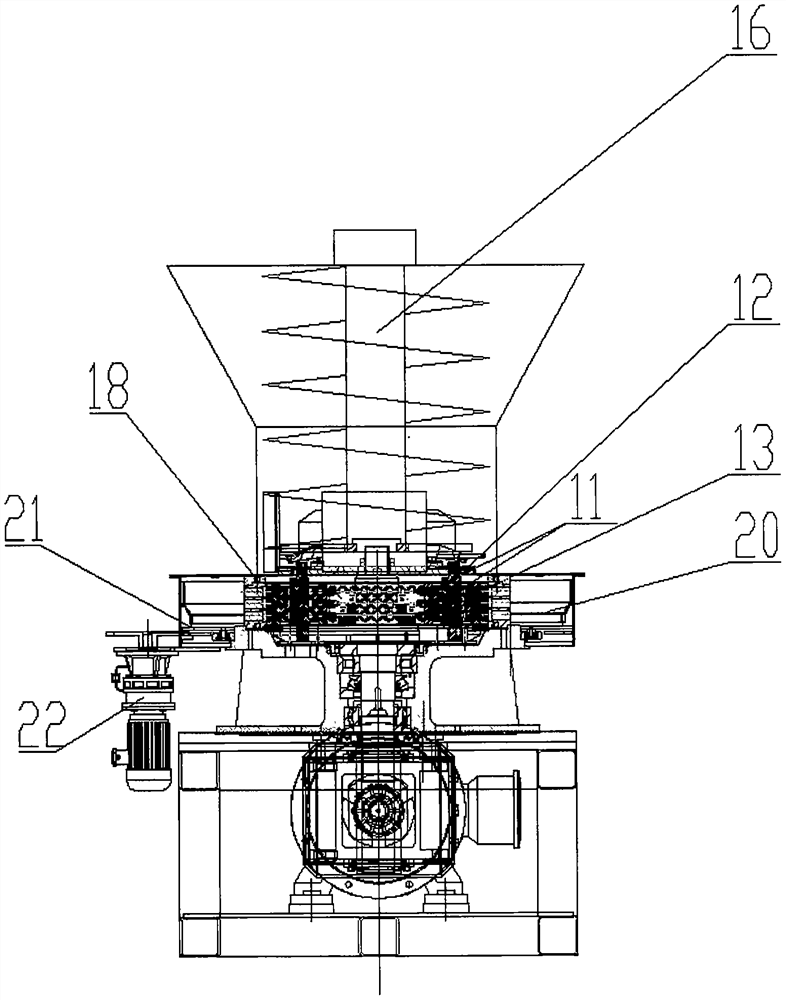

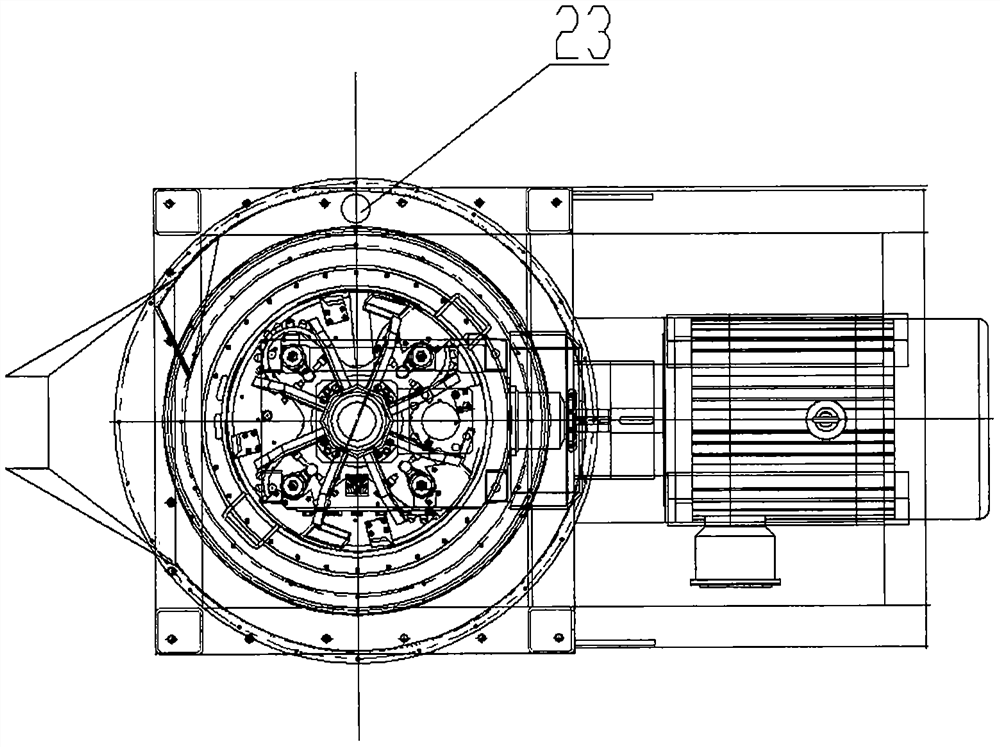

[0028] The embodiment of the present invention proposes a device for punching and forming materials by means of meshing, including a frame 1, a main drive motor 2 is installed on the right side of the frame 1, and a rainproof cover is provided on the top of the main drive motor 2, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com