Auxiliary tool and method for hoisting laminated plate

An auxiliary tool and a technology of laminated panels, which are applied in the directions of transportation, packaging, and load-hanging components, etc., can solve problems such as damage to laminated panels, delay in construction period, and rework, and achieve the effects of simple processing, improved installation efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

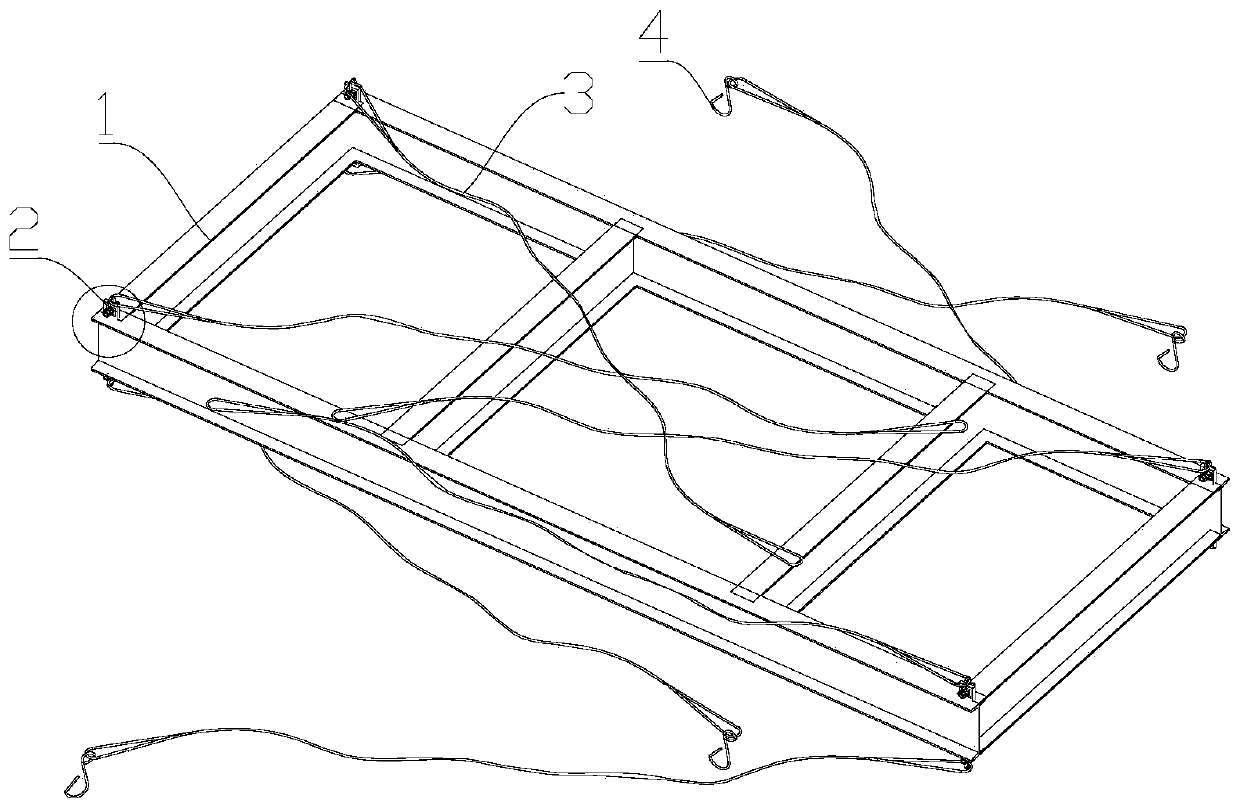

[0053] Such as figure 1 As shown, an auxiliary tool for hoisting a laminated plate, including a support frame 1, a connecting structure 2 and a sling;

[0054] Support frame 1: used to support the laminated board;

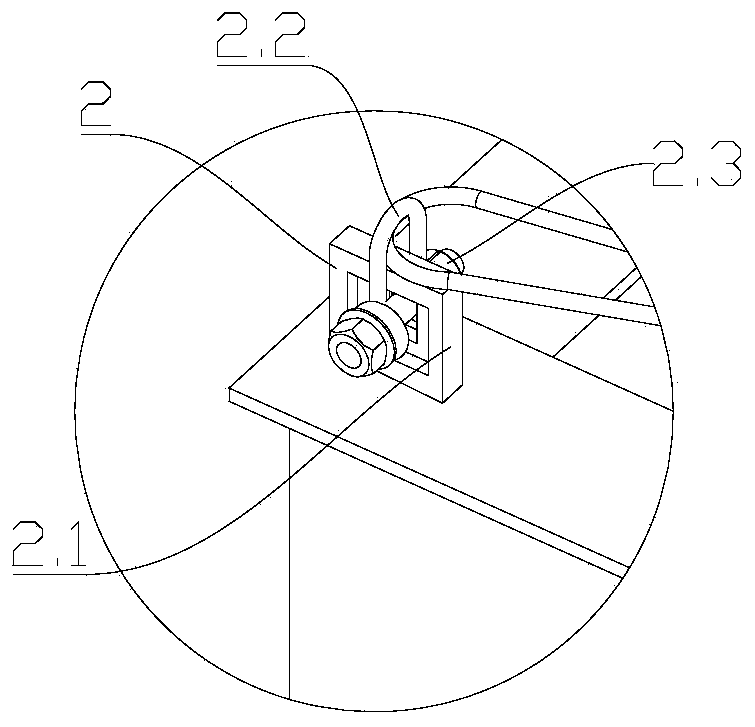

[0055] Connection structure 2: for connecting the support frame 1 and the suspension rope;

[0056] Sling: used for hoisting the support frame 1 during hoisting;

[0057] The support surface of the support frame 1 is a plane, and before hoisting, the laminated board needs to be placed flatly on the support plane of the support frame 1;

[0058] During the hoisting process, the inclination angle of the support surface is guaranteed to be no greater than 10° through the action of the connection structure 2 and the sling; further, during the hoisting process, the support surface of the support frame 1 remains horizontal.

[0059] The supporting frame 1 is provided with hanging point positions, and the connecting structure 2 is fixed at the hanging point positions. ...

Embodiment 2

[0071] An auxiliary hoisting method for hoisting laminated panels, including the aforementioned auxiliary tools;

[0072] Specifically include the following steps:

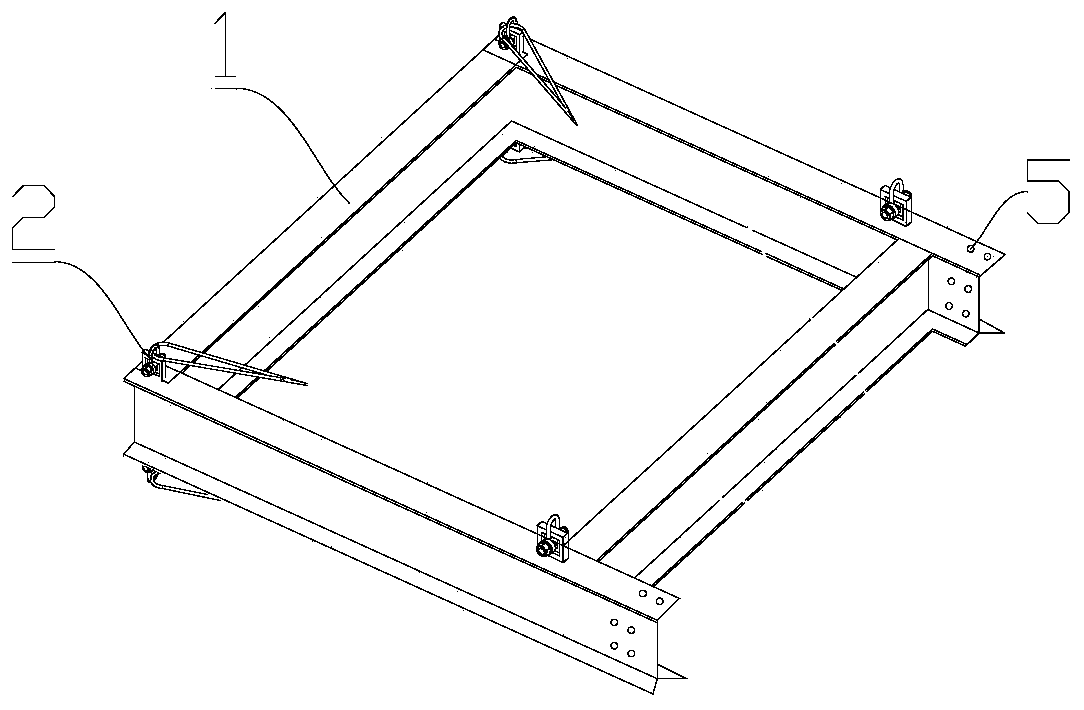

[0073] Steps for preparation of the support frame 1: first determine the size of the support frame 1 according to the size of the laminated board; select the existing support frame 1 or make the support frame 1 according to the size of the support frame 1;

[0074] The sub-steps of making support frame 1:

[0075] If the support frame 1 is an integral support: cut the I-beam according to the size of the hoisting tool, and weld it into a whole with electric welding after cutting;

[0076] If the support frame 1 is an assembled support: determine the number of assembly units required according to the size (note that the size of the assembly units can be made inconsistent, which is convenient for flexible assembly), and the assembly units (including connecting hinges and / or connecting plates 6 ) assembled into a br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com