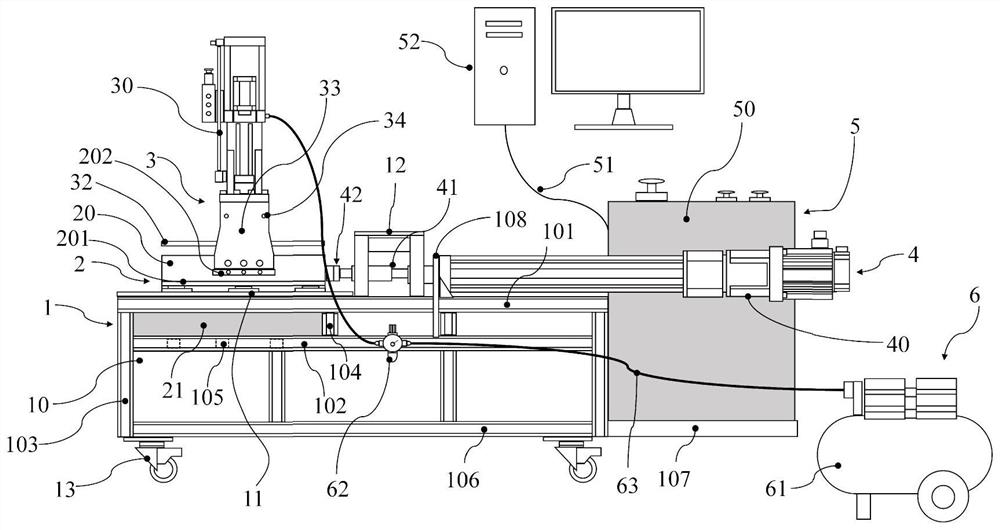

Large interface shearing equipment and implementation method thereof

A shearing equipment and interface technology, applied in the direction of using a stable shear force to test the strength of materials, using a stable tension/pressure test to test the strength of materials, and measuring devices, etc. Difficulty in accurate measurement of normal stress, compressive stress and normal pressure drop, etc., to achieve the effect of rich types, saving test time and reducing sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

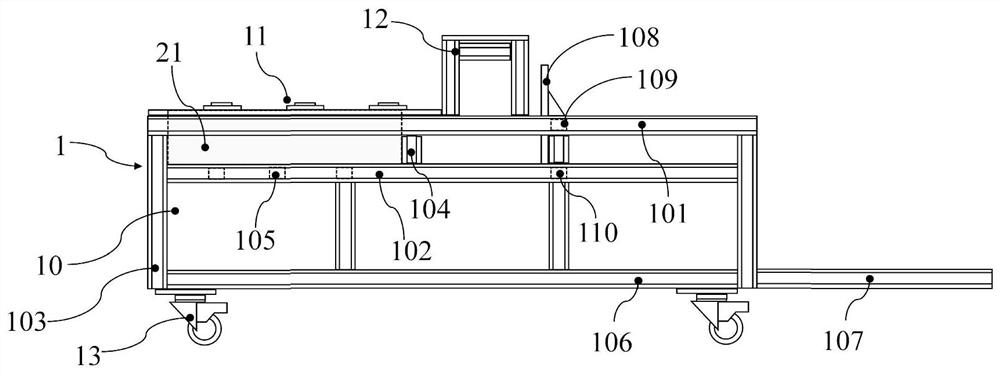

Method used

Image

Examples

Embodiment approach

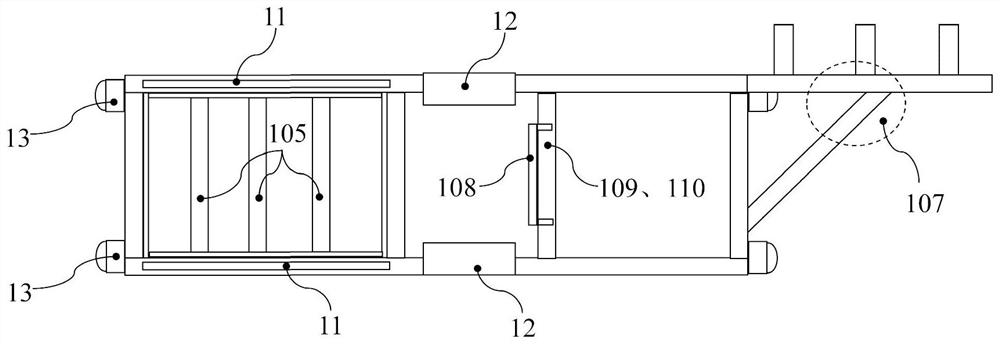

[0049] This embodiment also provides a method of implementing different material interface shear tests using the above-mentioned large interface shear equipment, including the following steps:

[0050] (1) The normal pressure loading device is transported to the bracket device through the lift bar;

[0051] (2) Place the material having a large strength in the interface shear test material into the lower shear box;

[0052] (3) Handle the normal pressure loading device from the carriage device by lifting the rod and placed on the positioning shelf, and is connected to the upper shear box;

[0053] (4) Put the material with weaker intensity in the interface shear test material into the upper shear box;

[0054] (5) Open the air compressor inputs compressed air to the air pressure booster cylinder, then the air pressure boost cylinder works and applies a pressure in the upper shear box by the pressure loading plate; during this process, the figures can be protected from the air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com