Steel for air chamber of drilling pump and production method of steel

A production method and air bag technology, which is applied in the field of metallurgical iron and steel materials, can solve the problems of not being able to meet the requirements of strength and toughness, long production cycle, and high cost, and achieve the effects of increasing brand effect, reliable quality, and reducing heat treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

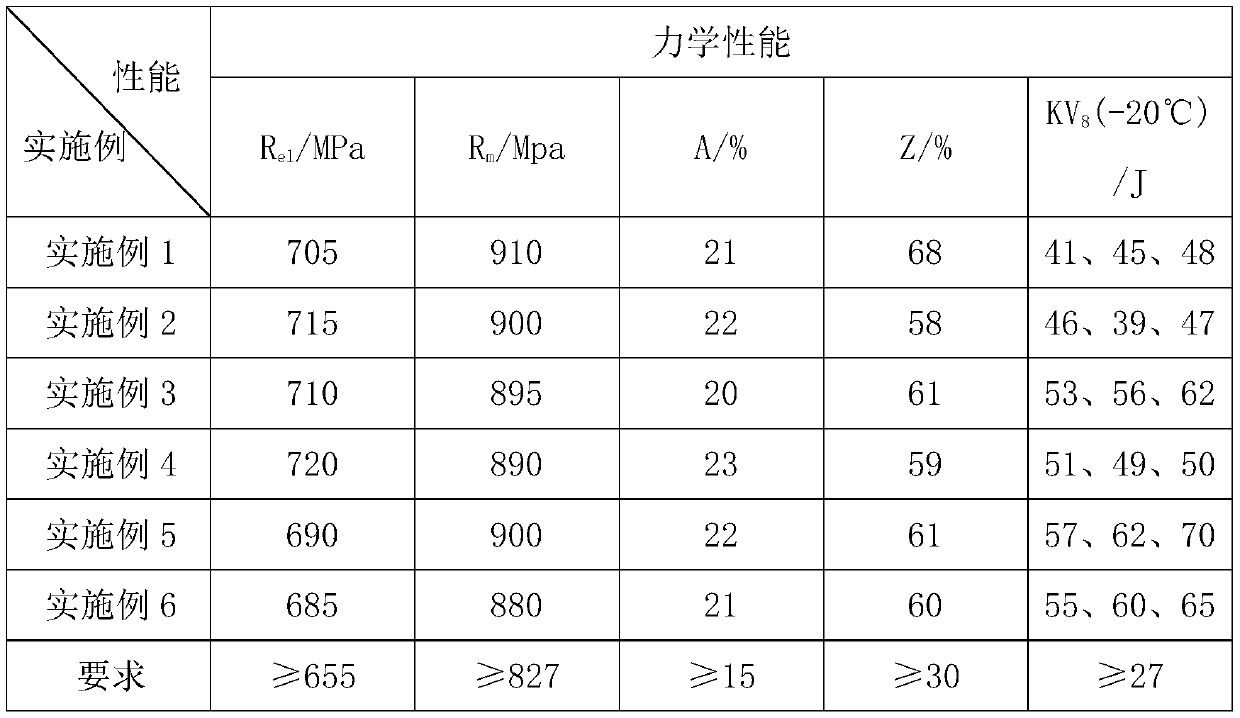

Examples

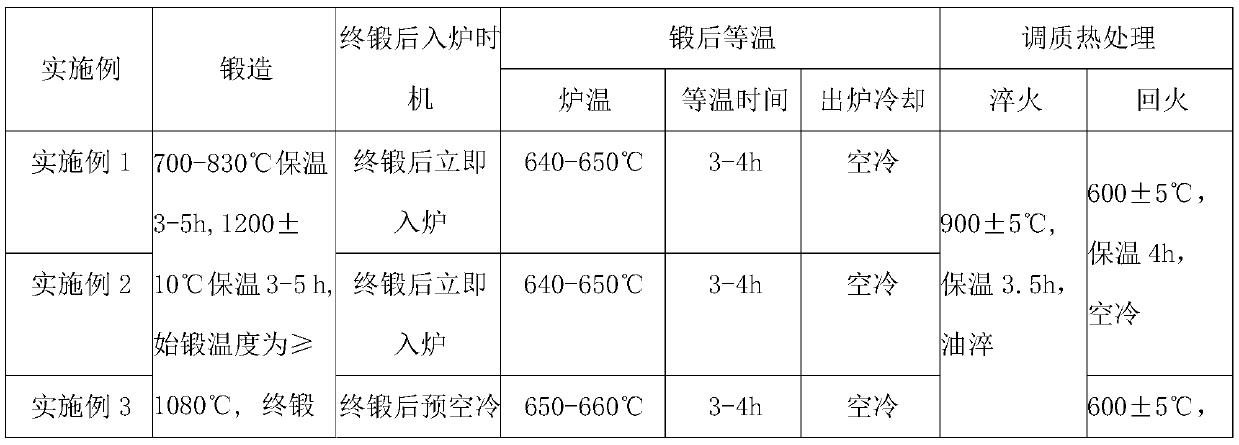

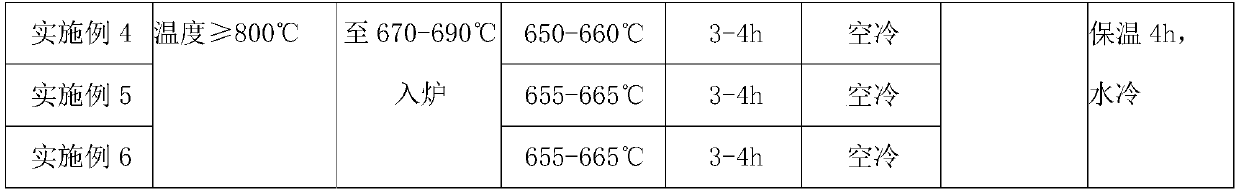

Embodiment 1- Embodiment 6

[0032] A kind of steel for the air bag of the drilling pump, the steel for the air bag of the drilling pump contains the following chemical composition (smelting analysis) in the weight percentage: see the following table 1.

[0033] Table 1 The chemical composition wt% of Example 1-Example 6, the rest is iron and unavoidable impurity elements.

[0034] Example C Si mn P S Cr Ni Mo V Nb N Al Example 1 0.30 0.19 0.52 0.010 0.003 0.98 0.20 0.21 0.012 0.021 0.0065 0.021 Example 2 0.32 0.21 0.55 0.009 0.002 1.03 0.21 0.22 0.015 0.017 0.0070 0.022 Example 3 0.31 0.22 0.57 0.008 0.002 1.05 0.21 0.23 0.018 0.022 0.0073 0.025 Example 4 0.33 0.21 0.56 0.007 0.001 1.07 0.22 0.24 0.021 0.024 0.0078 0.023 Example 5 0.31 0.23 0.58 0.006 0.004 1.04 0.21 0.22 0.019 0.028 0.0085 0.026 Example 6 0.31 0.22 0.56 0.007 0.003 1.05 0.22 0.21 0.023 0.020 0.0090 0.025

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com