A fast and selective method for reducing micropipe and dislocation density in SiC crystals

A selective, crystallographic technology, applied in the direction of chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems that the dislocation density cannot be reduced, there is no effective method, and the micropipe and dislocation density can be reduced to achieve shortening Optimize time, optimize single crystal quality, and reduce genetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

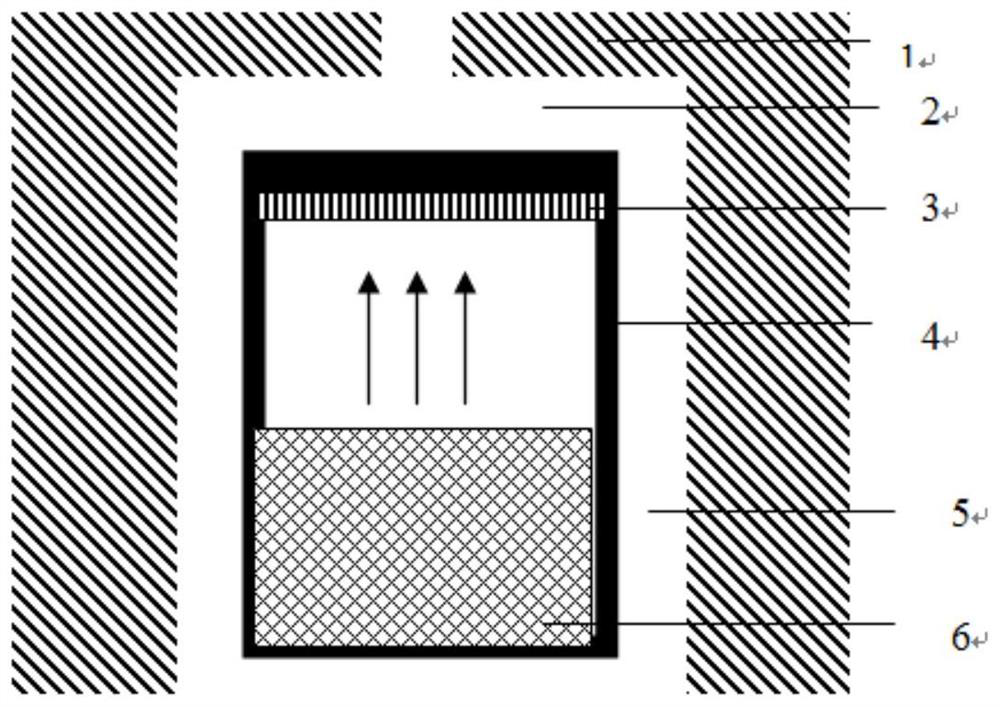

[0039] A method for rapidly and selectively reducing the density of micropipes and dislocations in SiC crystals, comprising the following steps:

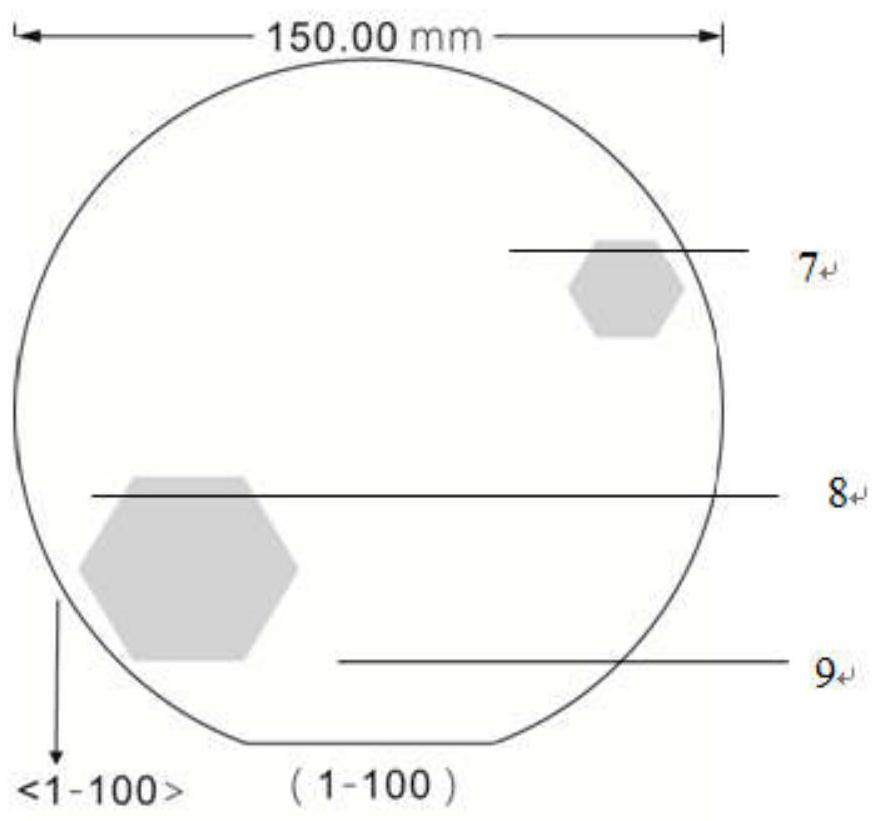

[0040] (1) Select the microtubule density -2 , dislocation density ≤10 3 cm -2 The SiC region of the crystal is cut into a 6-fold symmetrical crystal whose side is a polar surface, and the cut crystal is polished to remove the cut damage layer;

[0041] (2) The symmetric crystal treated in step (1) is fixed on the multi-micropipe multi-dislocation region of the SiC seed crystal with graphite glue. The crystal form of the crystal in step (1) is the same as that of the SiC seed crystal in step (2). consistent type;

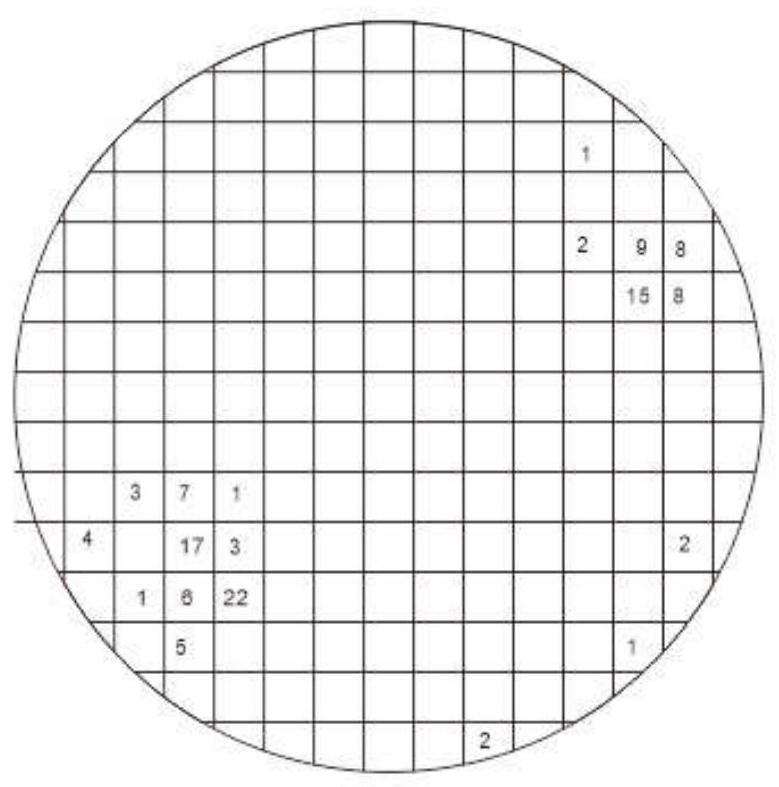

[0042] (3) The SiC seed crystal treated in step (2) is subjected to two-stage crystal growth, the first stage: low temperature and low pressure to promote lateral growth, the low temperature and low pressure growth temperature is 1700°C, the pressure is 1mbar, and the growth time is 10h; Microtubule density -2 , disloc...

Embodiment 2

[0050] A method for rapidly and selectively reducing the density of micropipes and dislocations in SiC crystals, comprising the following steps:

[0051] (1) Select the microtubule density -2 , dislocation density ≤10 3 cm -2 The SiC region of the crystal is cut into a 3-fold symmetrical crystal whose side is a polar surface, and the cut crystal is polished to remove the cut damage layer;

[0052] (2) The symmetric crystal treated in step (1) is fixed on the multi-micropipe multi-dislocation region of the SiC seed crystal with graphite glue. The crystal form of the crystal in step (1) is the same as that of the SiC seed crystal in step (2). consistent type;

[0053] (3) The SiC seed crystal treated in step (2) is subjected to two-stage crystal growth, the first stage: low temperature and low pressure to promote lateral growth, the low temperature and low pressure growth temperature is 1900°C, the pressure is 2mbar, and the growth time is 8h; Microtubule density -2 , disloca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com