Patents

Literature

37results about How to "Enhance brand effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

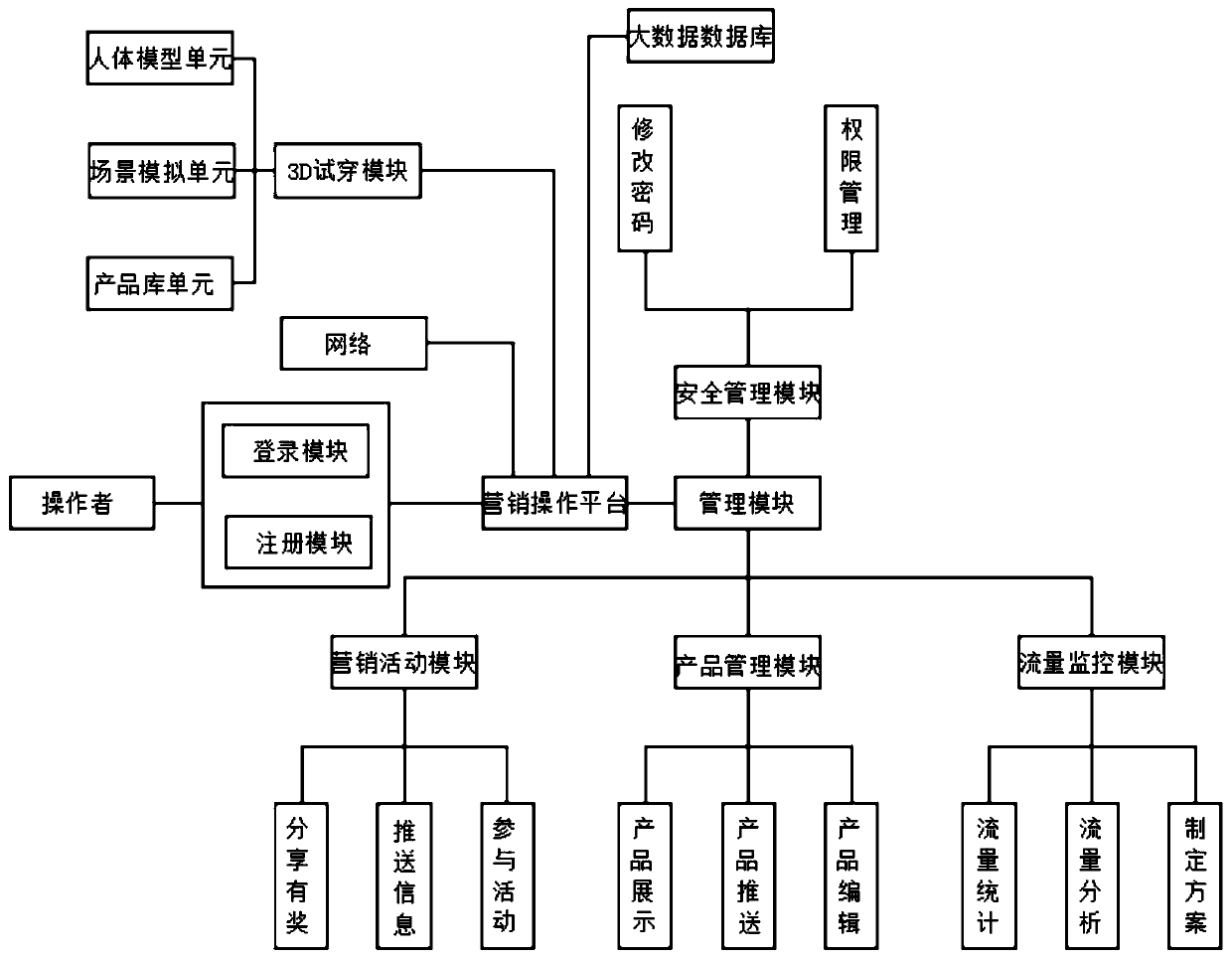

Marketing automation management platform system and management method thereof

PendingCN110245178AReduce input and output operationsImprove system efficiencyDatabase management systemsOffice automationData acquisition unitProcess engine

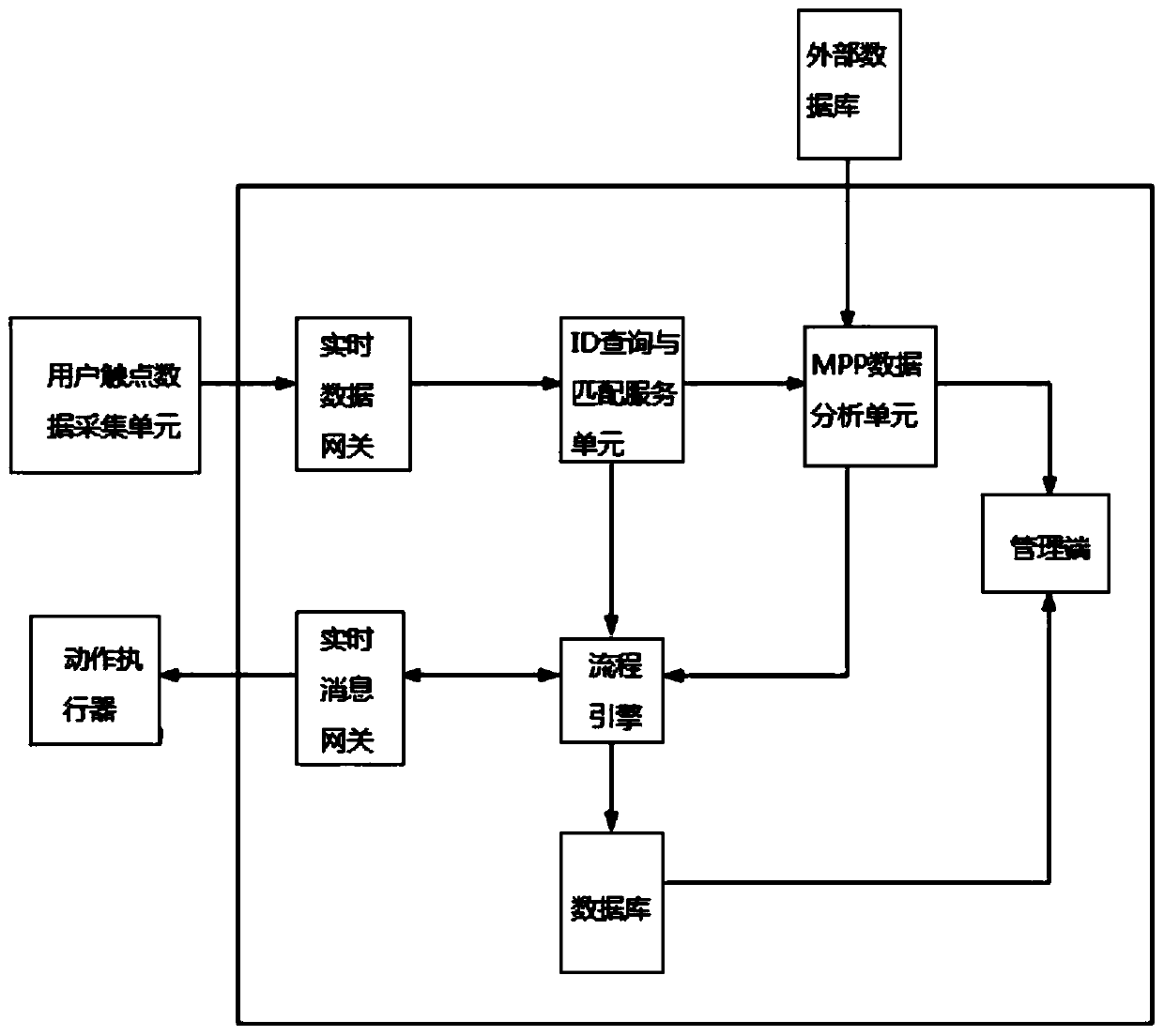

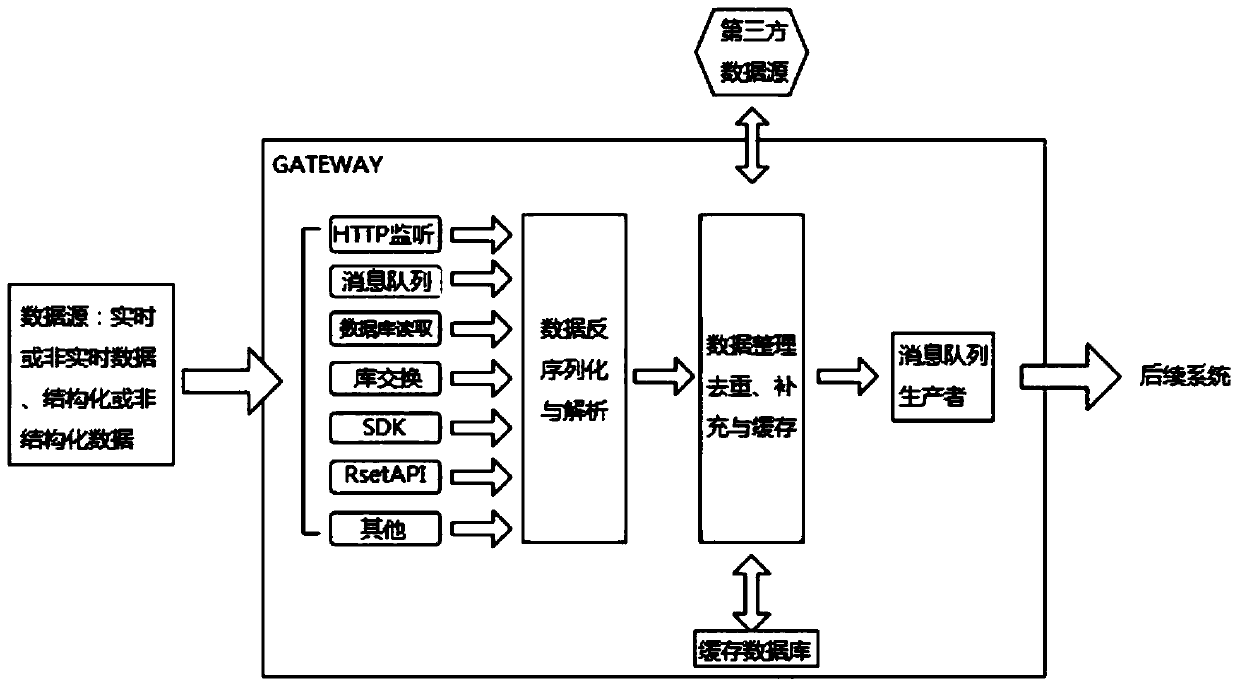

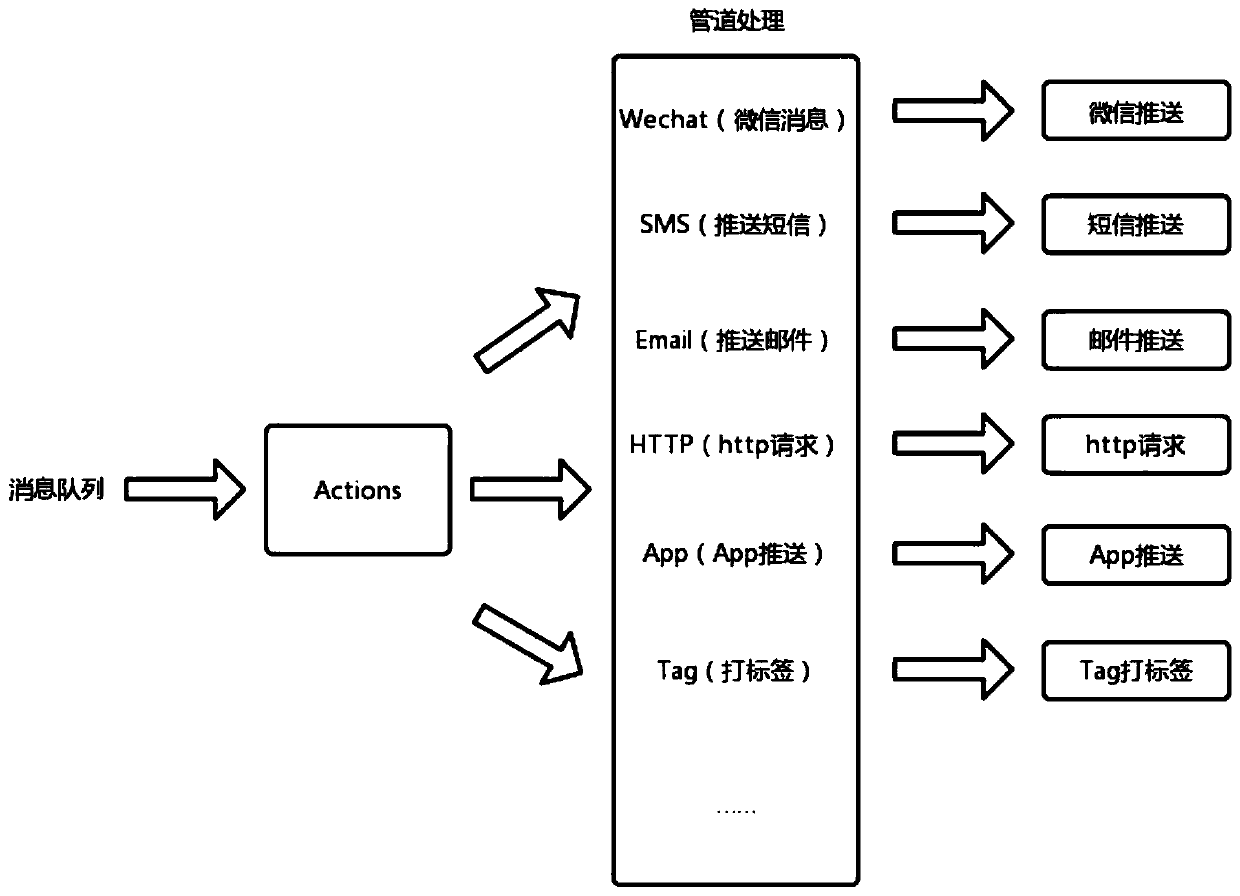

The invention relates to a marketing automation management platform system and a management method thereof. The marketing automation management platform system comprises a client contact data acquisition unit, a real-time data gateway, an ID query and matching service unit, an MPP data analysis unit, a process engine, a management end, a real-time message gateway and an action actuator, wherein the client contact data acquisition unit is connected to the real-time data gateway; the real-time data gateway is connected with the ID query and matching service unit; the ID query and matching service unit is respectively connected with the MPP data analysis unit and the process engine; the process engine is connected with the real-time message gateway; the real-time message gateway is connected with the action actuator; and the MPP data analysis unit is respectively connected with the process engine and the management end. The marketing automation management platform system is good in timeliness, high in accuracy and capable of achieving automation.

Owner:上海矩云信息技术有限公司

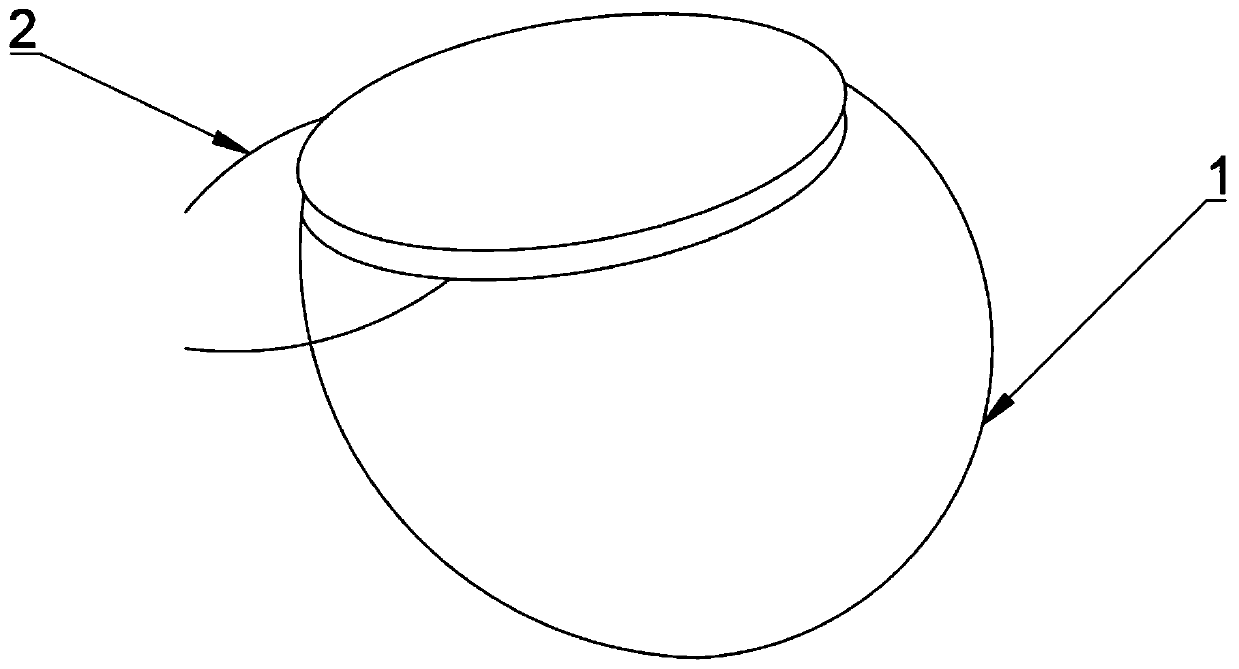

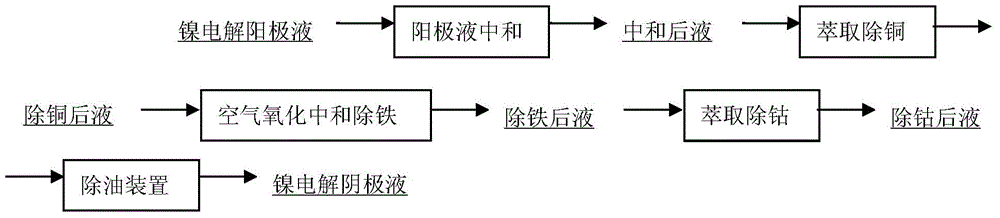

Preparation method for reducing sulfur impurities in electrolytic nickel

ActiveCN103498169AImprove sulfur contentSulfur content can be controlledElectrolysis componentsPhotography auxillary processesElectrolysisVulcanization

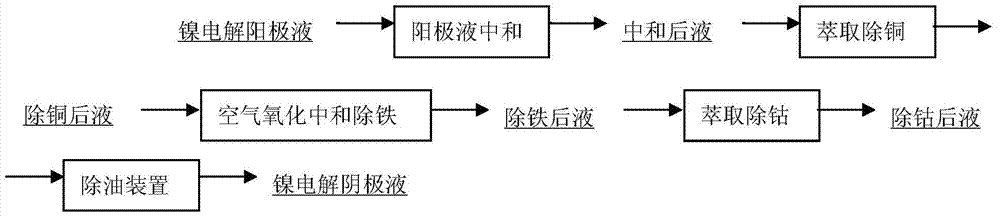

The invention discloses a preparation method for reducing sulfur impurities in electrolytic nickel, belonging to the technical field of wet-process metallurgy. The preparation method comprises the following steps of casting nickel matte into an anode plate, and putting the anode plate in an electrolytic bath to perform vulcanization so as to directly electrolyze a nickel anode; taking a nickel starting sheet produced in a starting sheet cell as a cathode, and putting the cathode into a diaphragm bag; putting purified electrolyte into a cathode chamber, wherein the liquid level of the cathode chamber is higher than that of an anode chamber to ensure that an anode liquid can not enter the cathode chamber; electrifying in the electrolytic bath to generate electrolytic nickel; purifying the anode liquid, namely performing four-stage purification including copper removal through extraction, iron removal through oxidation neutralization, cobalt removal through extraction and sulfur reduction. The sulfur impurities in the electrolytic nickel generated through normal electrolysis is less than 0.001%, and the average content of the sulfur impurities is 0.0005%. According to the preparation method disclosed by the invention, a normal soluble anode is used as a template, and the content of the sulfur impurities in an electrolytic nickel plate is reduced by reducing the sulfur content in the cathode liquid, so that an electrolytic nickel finished product with extremely low content of the sulfur impurities is obtained. The process method is simple, and can effectively control the content of the sulfur impurities in the electrolytic nickel, and the obtained high-quality electrolytic nickel finished product can be widely applied.

Owner:JILIN JIEN NICKEL IND

Low-salt temperature change curing method of leaf mustard sauce products

ActiveCN104026522AReduce salt contentShorten curing cycleFood preparationBiotechnologyNutritive values

The invention discloses a low-salt temperature change curing method of leaf mustard sauce products. The leaf mustard sauce product comprises the following raw materials in parts by weight: leaf mustard 280-300, Welsh onion 30-40, garlic 20-30, five spice powder 15-25, red Chilli powder 10-20, pepper powder 7-15, oyster juice 10-15, vegetable oil 10-15, and salt 15-30. The curing method adopts the low-salt temperature change curing technology and the multi-strain coupling fermentation technology and also adopts three-time cooling salt-reduction and two-time desalination way, so as to effectively reduce the salt content of the sauce pickles and shorten the curing period; with regard to the multi-strain coupling fermentation technology, the multiple pure strain mixing starter-making can be artificially controlled, the period can be shortened, and the quality and flavor can be improved, so that the obtained leaf mustard sauce products have features of pure sauce color, low salt, high crispness, rich essential amino acids and diet fibers, unique flavor and high nutrition value.

Owner:HUBEI UNIV OF TECH

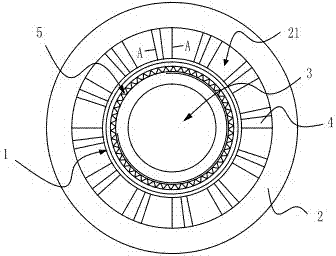

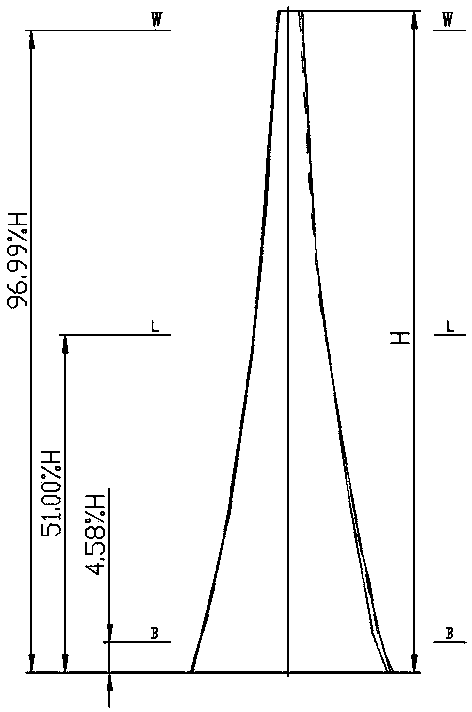

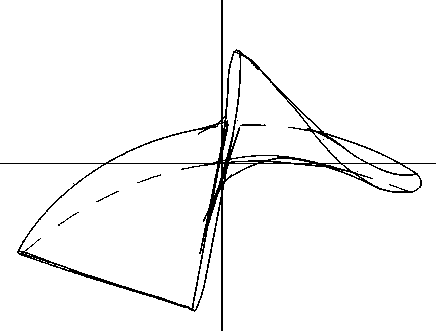

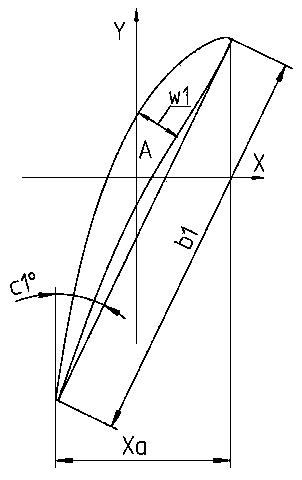

Semi-rotation speed nuclear turbine final stage moving blade

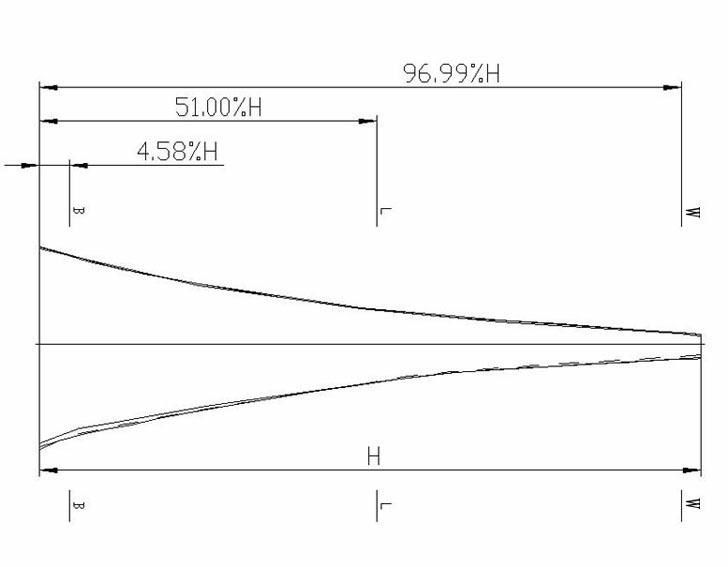

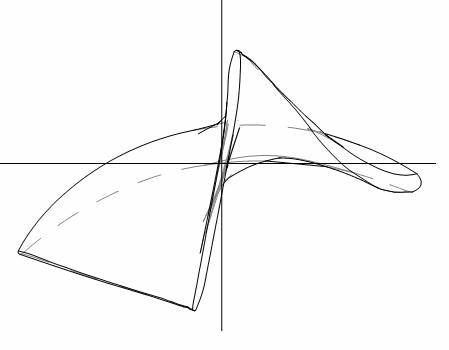

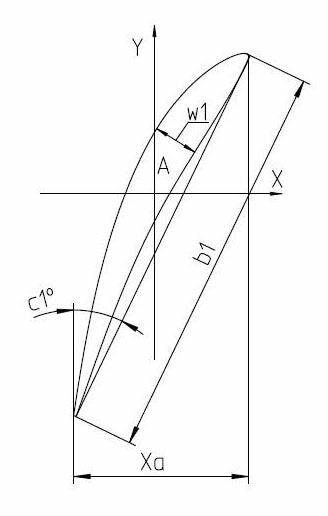

ActiveCN102108883ACross section with excellent aerodynamic performanceReasonable change in areaBlade accessoriesMachines/enginesEngineeringTurbine

The invention relates to a semi-rotation speed nuclear turbine final stage moving blade. A blade molded line is a variable cross-section torsion molded line. The semi-rotation speed nuclear turbine final stage moving blade has the following characteristic parameters: installation angle c1, chord length b1, maximum thickness w1, axial width Xa and sectional area A; a relative value of the height H of the blade increases monotonically from 0.1 to 1.0; an absolute value c1 of the installation angle decreases monotonically from 80.990 to 10.80; the variation principle of the relative value of the chord length b1 from a root sectional area to a top sectional area is that b1 is not greater than 1.557 and not less than 1.0; the variation principle of the relative value of the maximum thickness w1 from the root sectional area to the top sectional area is that w1 is not greater than 1.9465 and not less than 1.0; the variation principle of the relative value of the axial width Xa from the root sectional area to the top sectional area is that Xa is not greater than 8.387 and not less than 1.0; the variation principle of the relative value of the area A from the root sectional area to the top sectional area is that A is not greater than 5.553 and not less than 1.0; and the blade is composed by the lamination and smooth transition of 25 characteristic sections with different profiles and shapes along a blade height direction, wherein three of the characteristic sections are key sections: a section at 4.58% of H, a section at 51.00% of H, and a section at 96.99% of H, and the theory profile lines of the sections are described by the coordinates (X, Y) of 28 discrete points.

Owner:DONGFANG TURBINE CO LTD

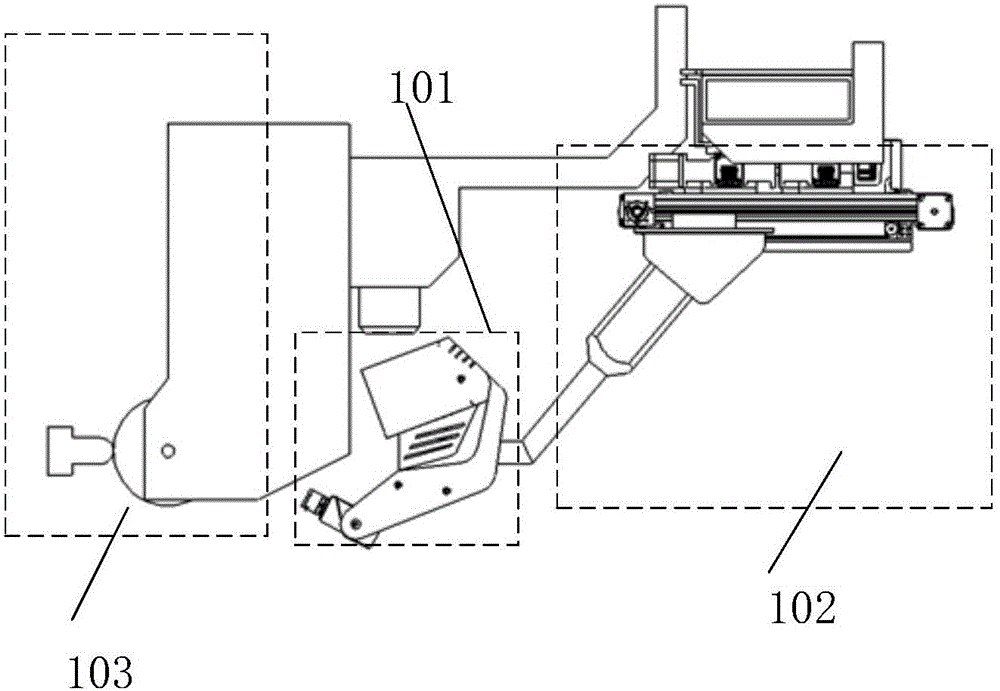

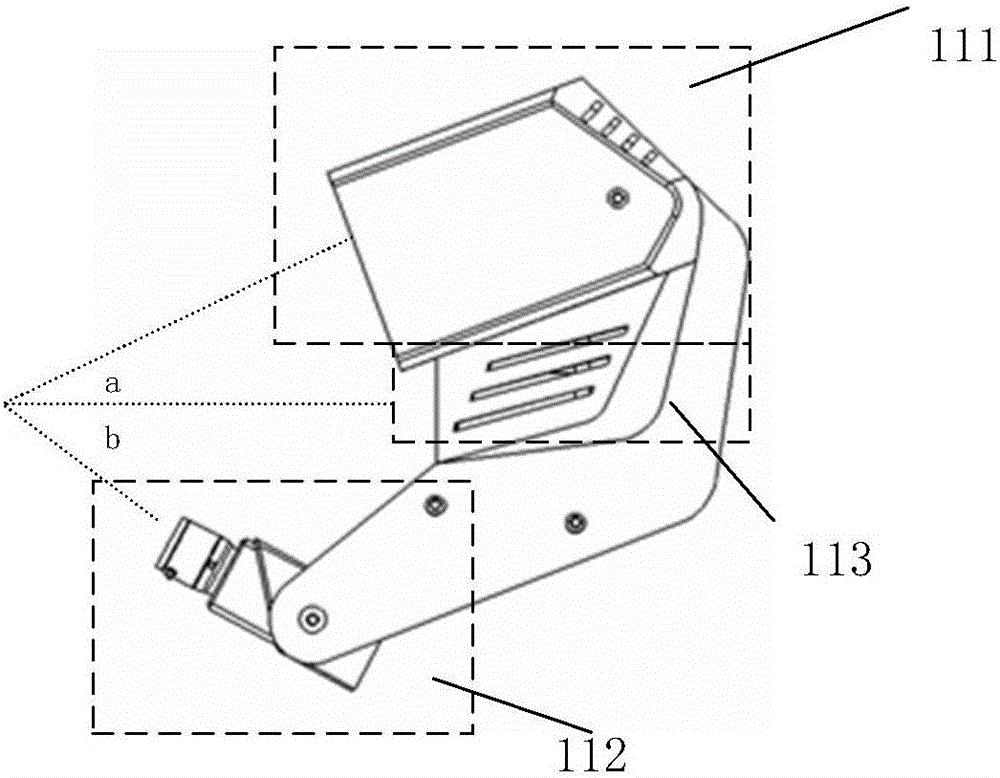

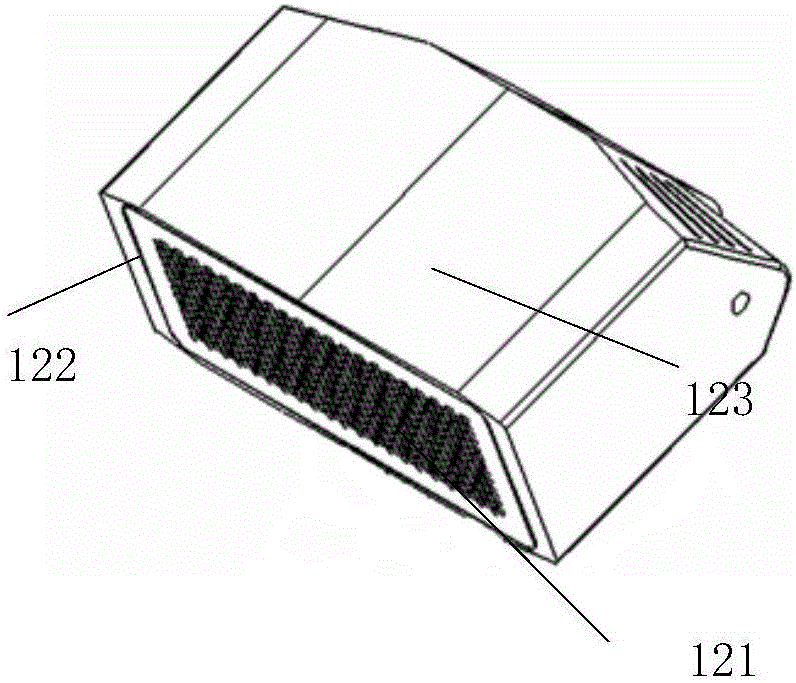

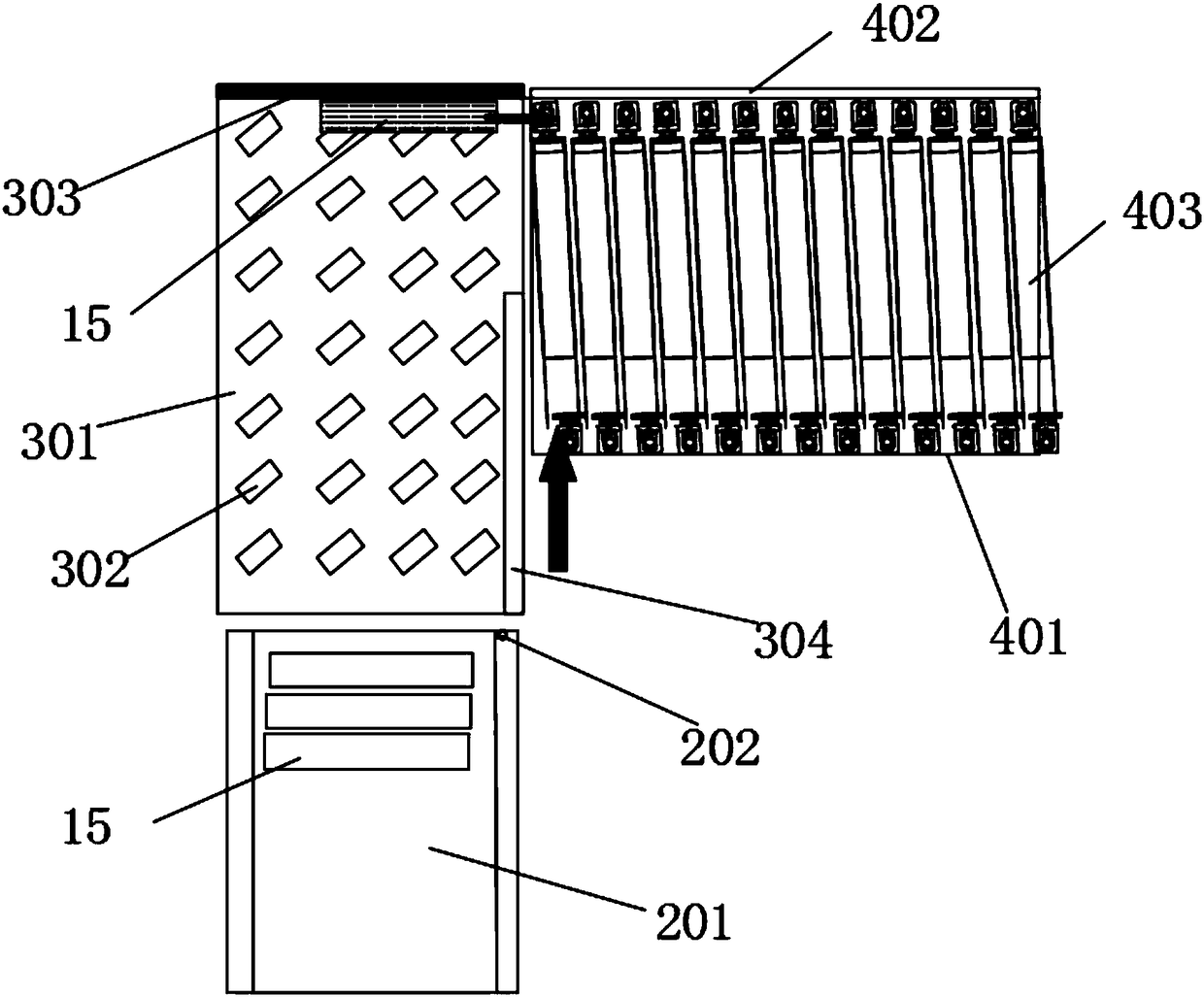

Wrinkle recognition method and apparatus for capacitor thin film

ActiveCN106529510AEnhance brand effectLow costCharacter and pattern recognitionWrinkle skinCapacitance

The invention discloses a wrinkle recognition method and apparatus for a capacitor thin film. The apparatus mainly comprises a honeycomb alignment weak light monitoring module, an adaptive focusing module and an image processing module, wherein the adaptive focusing module is matched with the honeycomb alignment weak light monitoring module to realize weak light detection of the thin film; and based on the image processing module, the quality and rolling defects of the thin film can be reasonably recognized. By adoption of the wrinkle recognition method and apparatus, an online image can be obtained; and through an image processing method, formation of the wrinkle of the thin film, and the position and the size of the wrinkle are monitored in real time, and product defects are marked in time, so that the problems existing in manpower inspection are solved while the blank of intelligent monitoring of the rolling production of the thin film at home and abroad is filled up.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

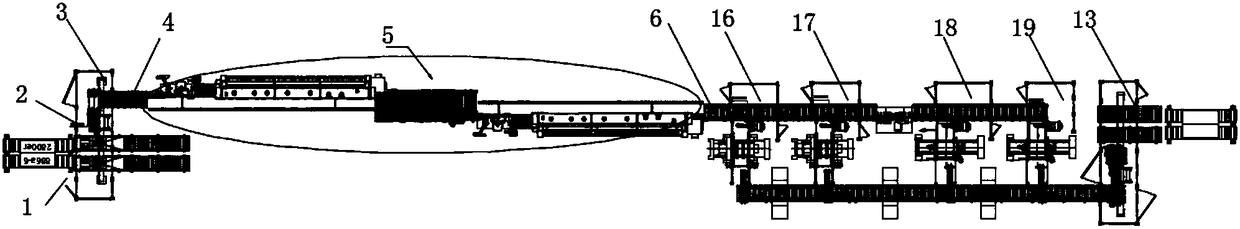

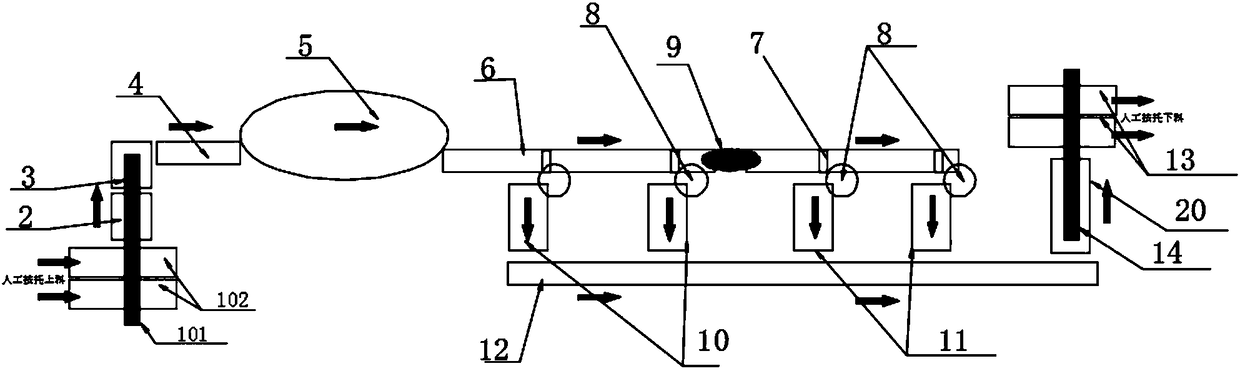

Automatic production process system for standard part

ActiveCN108556085AImprove satisfactionIncrease market shareMulti-purpose machinesTotal factory controlProcess systemsEngineering

The invention discloses an automatic production process system for a standard part. The automatic production process system comprises a loading device, a plate separating machine, a motion steering device, a beside conveyor, a left-right sealing machine, a main conveyor line and a plurality of processing stations which are arranged beside the main conveyor line, wherein the plate separating machine is a first conveyor belt; the motion steering device is a second conveyor belt with conveying speed greater than that of the first conveyor belt; a plurality of rows of non-power friction rollers which form included angles with a conveying direction of the second conveyor belt are arranged on the second conveyor belt, and a first baffle plate is arranged at the tail end of the second conveyor belt; the beside conveyor is arranged at the tail end of the second conveyor belt, and a beside baffle plate and a conveying inclined roller are arranged on the beside conveyor; the conveying inclined roller is used for providing friction force in an inclined forward direction along the beside baffle plate for a standard plate part on the conveying inclined roller; the left-right sealing machine isarranged at the downstream of the beside conveyor and is used for sealing left and right for the standard plate part conveyed from the beside conveyor; and the main conveyor line is used for conveyingthe sealed standard plate part on the main conveyor line to each processing station. The automatic production process system is high in degree of automation, can continuously produce the standard plate part, and is high in production efficiency.

Owner:索菲亚家居湖北有限公司

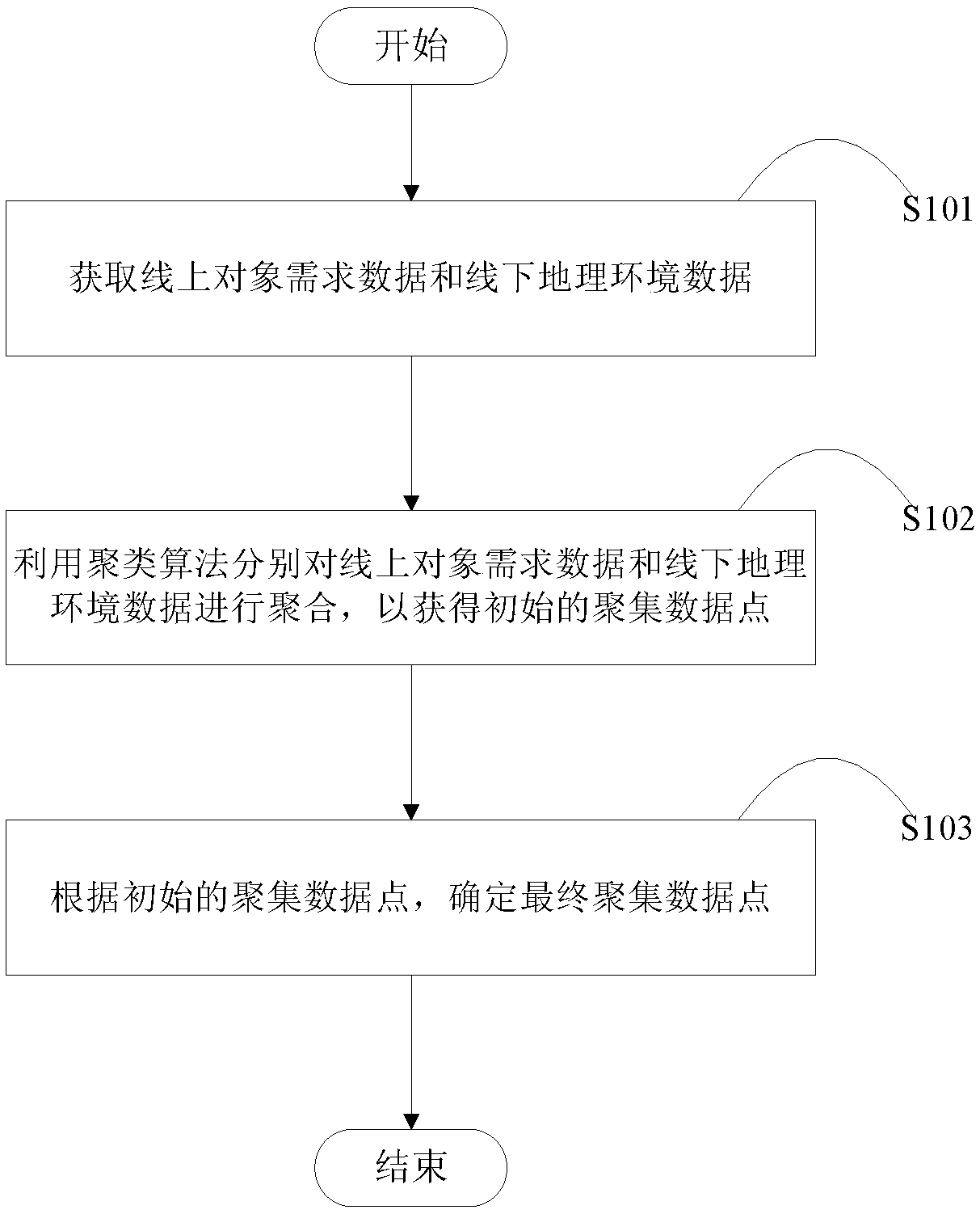

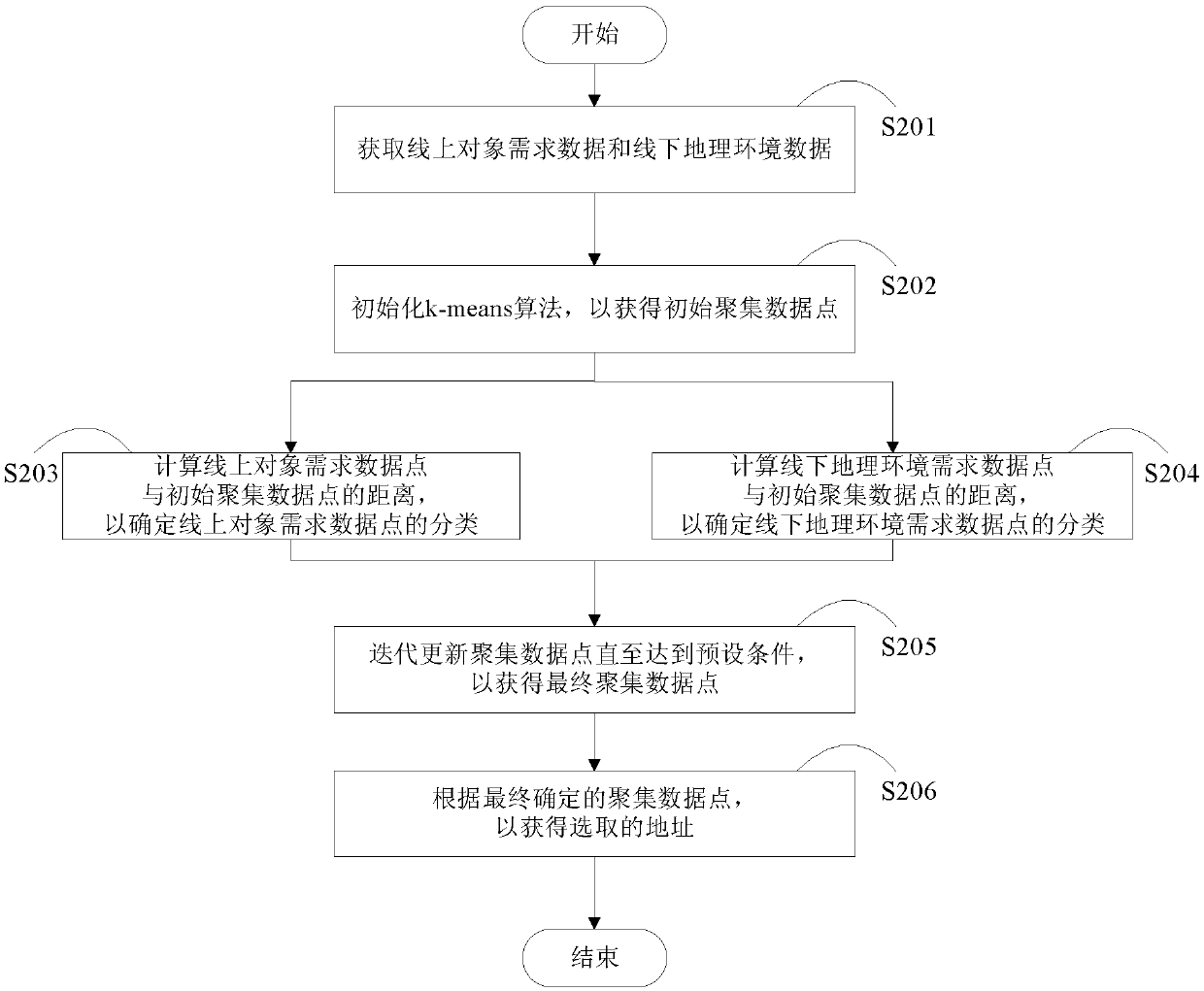

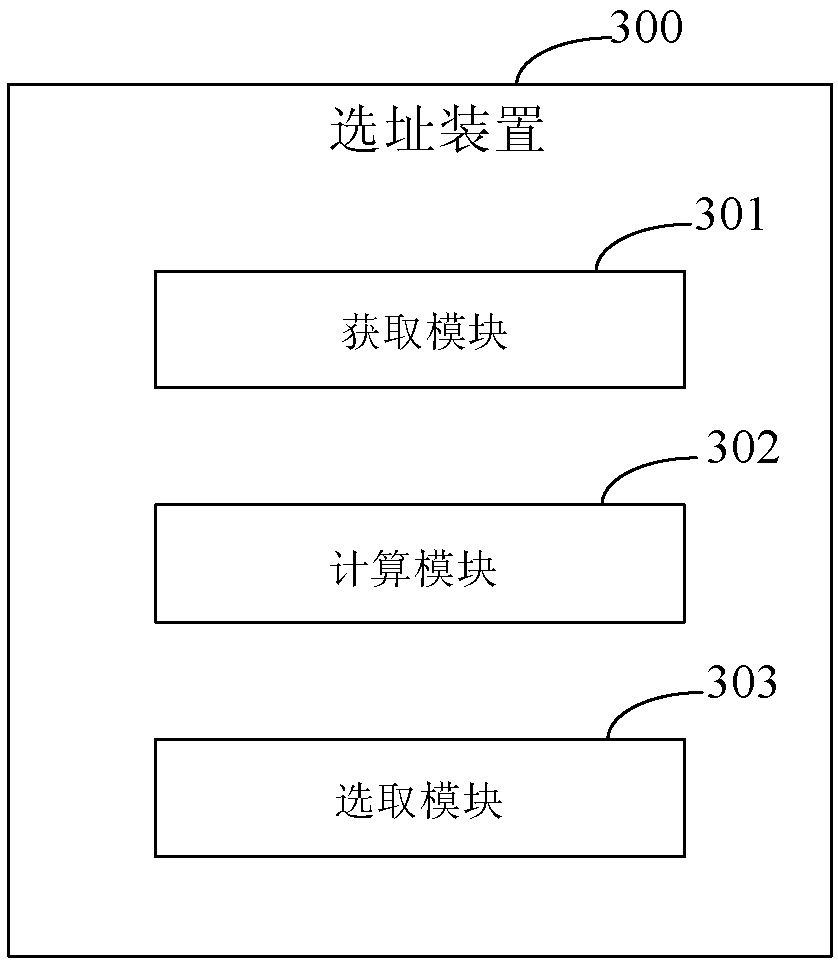

Address information generation method and device

PendingCN110008970AEnhance brand effectMaximize the benefitsCharacter and pattern recognitionBuying/selling/leasing transactionsCluster algorithmData science

The invention discloses an address information generation method and device, and relates to the technical field of computers. A specific embodiment of the method comprises the steps of obtaining online object demand data and offline geographic environment data; respectively aggregating the online object demand data and the offline geographic environment data by utilizing a clustering algorithm toobtain initial aggregated data points; and determining a final aggregated data point according to the initial aggregated data point. According to the embodiment, the problems of inaccurate address selection and low efficiency of the offline store in the prior art can be solved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

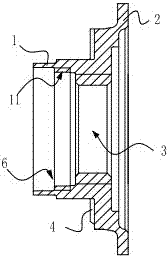

Novel axle head nut

The invention discloses a novel axle head nut which comprises a threaded connector and a locking flange, wherein the threaded connector is in threaded fit with an axle, and the locking flange and the threaded connector are integrally formed. An inner cavity capable of containing the axle is formed between the threaded connector and the locking flange, and a key connected with a hub of the axle is circumferentially arranged around the axis of the locking flange and on the back surface of the locking flange. The novel axle head nut is characterized in that a plurality of splines arranged along the axis direction of the threaded connector are circumferentially arranged on the inner wall of the threaded connector around the axis of the threaded connector in the inner cavity of the threaded connector, a fine-adjustment function for pre-tightening force of the axle head nut is achieved, a bearing is protected, the service life of the bearing is prolonged, so that the service life of the whole axle is prolonged, the strength of an axle body and the axle head nut cannot be affected while the fine-adjustment function is achieved, driving safety is ensured, a spline structure is formed once by forging and extruding, and the strength of the splines is ensured.

Owner:QINGTE GRP

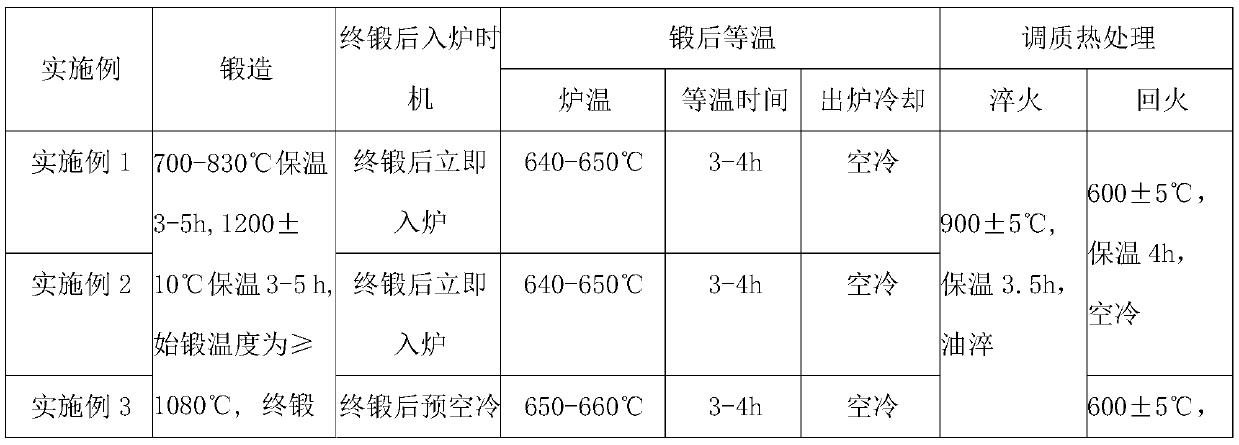

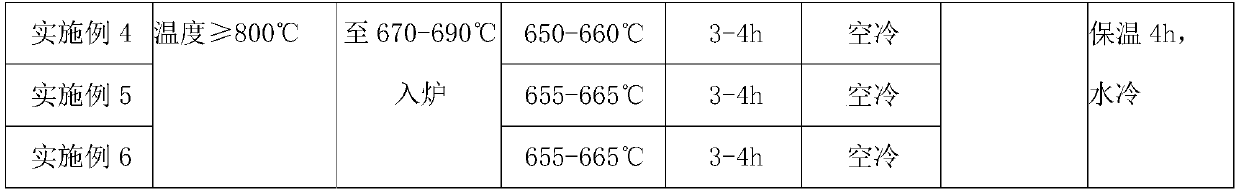

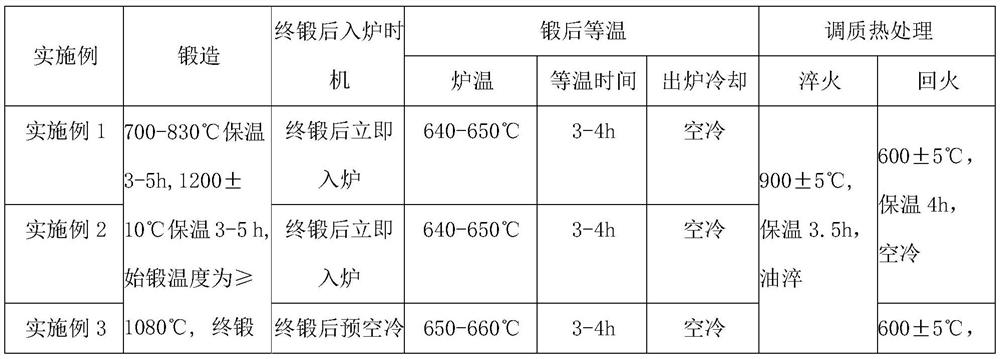

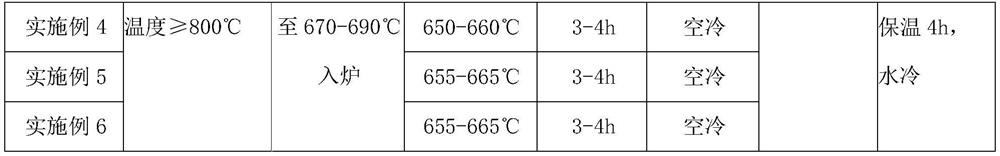

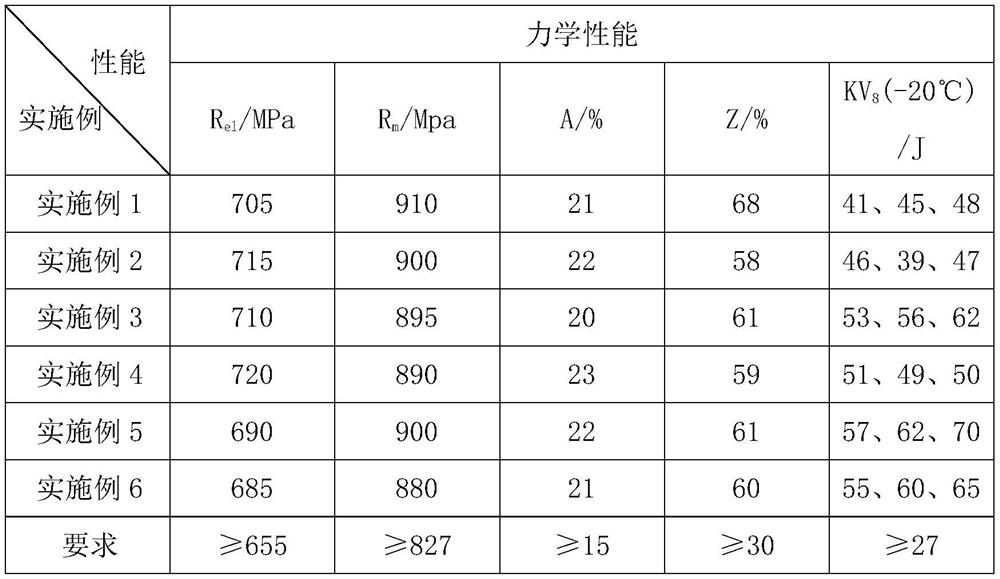

Steel for air chamber of drilling pump and production method of steel

The invention provides steel for an air chamber of a drilling pump and a production method of the steel. The steel comprises chemical components as follows: 0.29%-0.33% of C, 0.15%-0.35% of Si, 0.50%-0.60% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.95%-1.10% of Cr, 0.15%-0.25% of Ni, 0.15%-0.25% of Mo, 0.010%-0.025% of V, 0.015%-0.030% of Nb, 0.0060%-0.0100% of N, 0.018%-0.032% of Al and the balance iron and inevitable impurity elements. Compared with the prior art, by means of composition design of multi-element micro-alloying, forging waste heat isothermal annealing and heat treatment process optimization and on the premise of guaranteeing reliable quality of the air chamber, a normalizing procedure before quenched-tempered heat treatment is eliminated, the production cycle of the air chamber is shortened, and the heat treatment cost of users is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

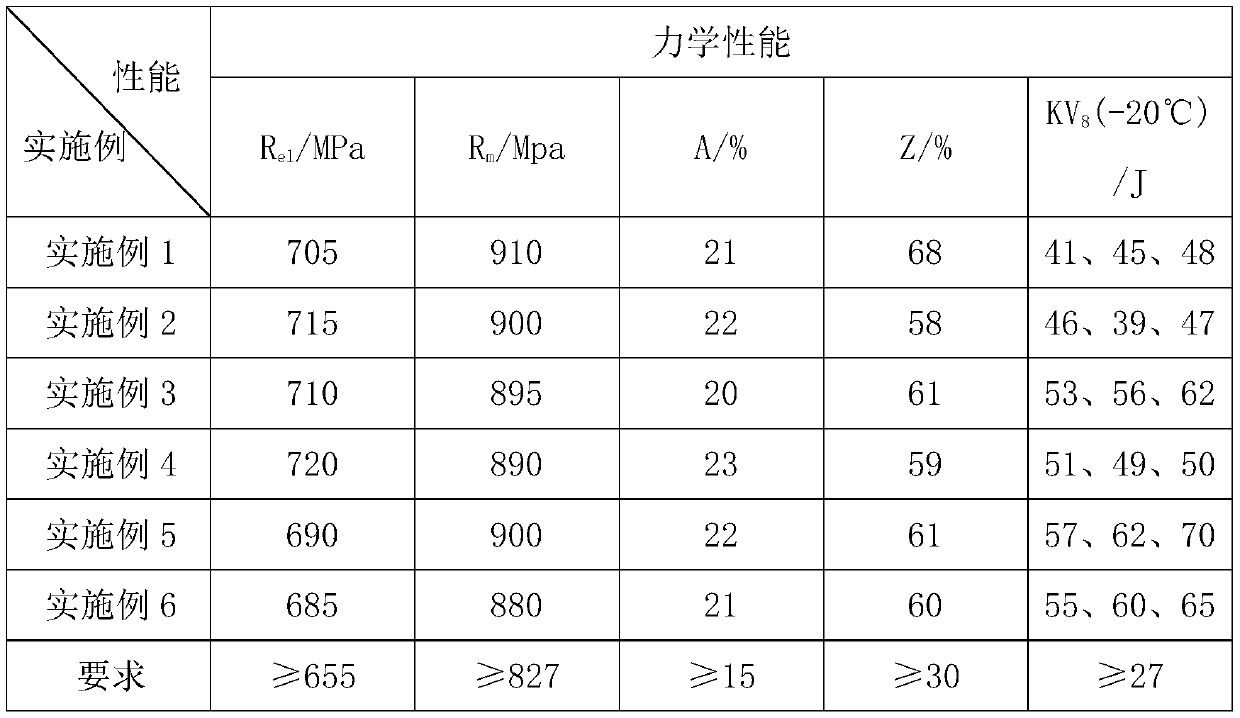

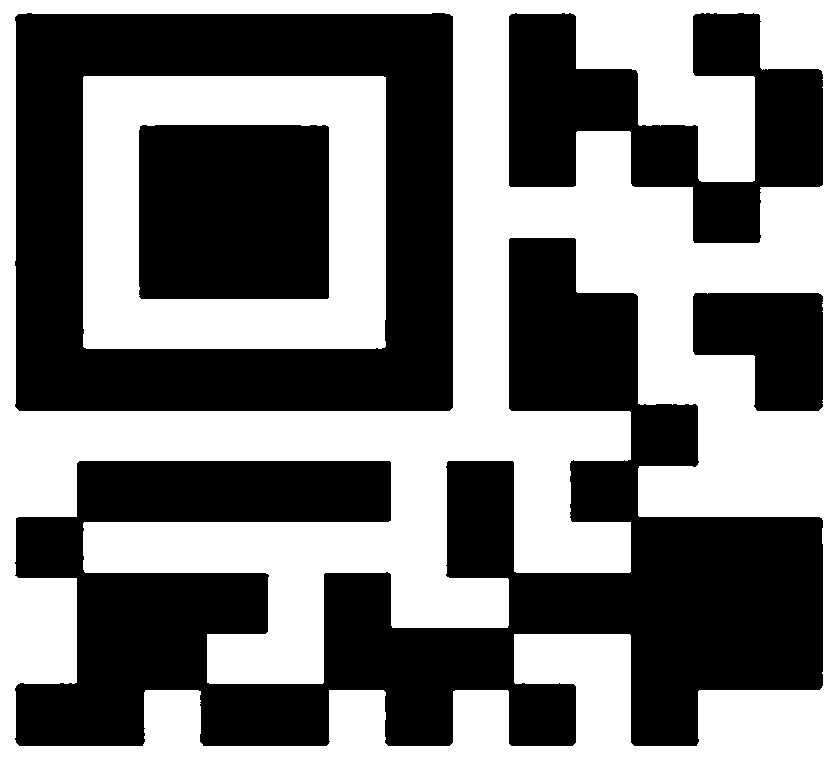

Method for generating two-dimensional code

ActiveCN106570550AImprove bindingImprove visual effectsRecord carriers used with machinesGraphicsDimensional modeling

The invention belongs to the technical field of two-dimensional codes, and particularly relates to a method for generating a two-dimensional code. The method comprises the steps of (1) determining a functional pattern and a data region R(M)c of a two-dimensional code; (2) dividing the data region R(M)c into pixel matrixes according to black and white pixels of the data region R(M)c, and then calculating different rule patterns formed by the black pixels in the data region R(M)c by using a pattern judgment algorithm; and (3) replacing the different rule patterns with preset pictures. For a new propaganda link, a beautified two-dimensional code picture can be generated immediately according to the method, and the personnel cost and the production time loss of employing an art designer for a long term for realizing the similar effect are greatly saved. In addition, a two-dimensional code generated according to the method is good in anti-counterfeiting performance.

Owner:宁波邻家网络科技有限公司

Manufacturing process of temperature-sensing color-changing floor

PendingCN114311199AImprove environmental comfortIncrease the fun of useWood treatment detailsSpecial surfacesSolid woodMaterials science

The invention belongs to the technical field of building materials, and relates to a manufacturing process of a temperature-sensing color-changing floor, which comprises the following steps of: assembling a solid wood surface board and a base material according to a conventional process, gluing a hot-pressed board, subdividing, repairing and sanding; performing antique wiredrawing or antique treatment on the surface, and then performing physical or chemical dyeing and drying; the surface of the floor is coated with the temperature-sensing color-changing coating through roller coating, and a temperature-sensing color-changing pattern is formed; or surface physical or chemical dyeing; or, the surface is not subjected to archaizing and dyeing treatment, the surface of the floor is coated with the temperature-sensing color-changing coating in a roller coating or spraying mode, and the temperature-sensing color-changing pattern is formed; uV adhesion paint, water-based / oil-based UV functional primer and water-based / oil-based UV functional finish paint are coated on the surface of the temperature-sensitive color-changing pattern, and UV drying is carried out; and grooving, checking and packaging. The surface color of the prepared floor is not changed any more and can be changed into a specific color at a specific temperature according to requirements, patterns can be customized, and the use safety and interestingness of a user are improved.

Owner:DAYA JIANGSU FLOOR

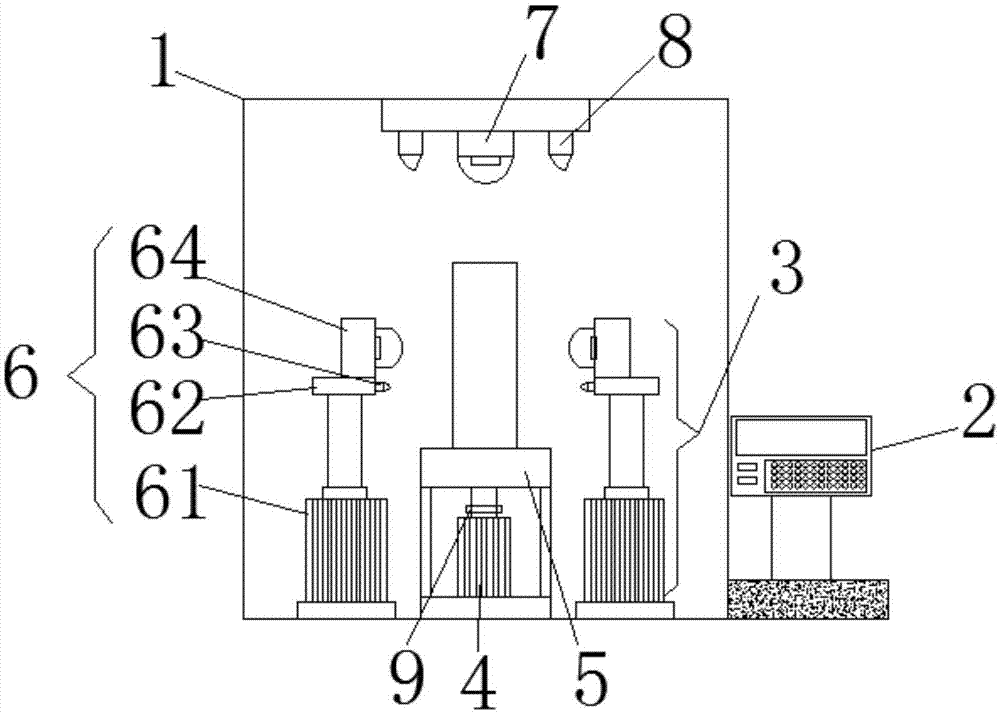

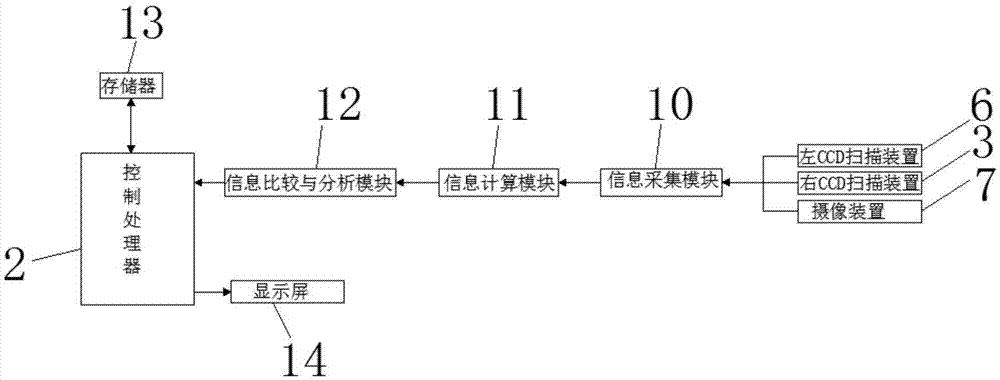

Efficient corrugated paper printing quality detection device

InactiveCN106872478APromote improvementEnhance brand effectOptically investigating flaws/contaminationAgricultural engineeringLED lamp

The invention discloses a high-efficiency corrugated paper printing quality detection device, which includes a housing, a control processor and a right CCD scanning device. A servo motor is installed at the inner bottom of the housing, and a load is installed on the top of the servo motor through a bracket. A turntable, a left CCD scanning device is installed at the left end of the inside of the housing, the left CCD scanning device includes a cylinder, a mounting plate, a first LED light, and a CCD scanner, and the right CCD scanning device is installed on the right side of the inside of the housing , and is symmetrical with the left CCD scanning device with respect to the vertical plane of the casing, the top inside the casing is equipped with a camera and a second LED light, and the second LED light is electrically connected to the control processor; the device is A high-efficiency, high-precision, no dead angle corrugated printing quality inspection device.

Owner:CHONGQING CITY FULING DISTRICT XIONGXIANG PAPER PROD CO LTD

Convenient instant nutritious fruit-vegetable colorful steamed rice rolls and preparation method thereof

InactiveCN109430753ARich tasteExcellent toneNatural extract food ingredientsFood ingredient functionsFood processing

The invention discloses convenient instant nutritious fruit-vegetable colorful Steamed rice rolls and a preparation method thereof, and belongs to the technical field of food processing. The steamed rice rolls are prepared by pulping the following raw materials in parts by weight with water: 250-400 parts of rice, 15-30 parts of tomatoes, 15-30 parts of spinach and 20-40 parts of roses. The steamed rice rolls can ensure the natural mouth feel of rice pulp, the tomatoes, the spinach and the roses, can be eaten by adopting an instant way or a direct microwave oven heating way, and are convenientto preserve and transport.

Owner:HANGZHOU NORMAL UNIVERSITY

Beautifying agent for recovered glass beer bottles

The invention discloses a beautifying agent for recovered glass beer bottles. The beautifying agent for recovered glass beer bottles comprises, by weight, 10 to 60% of food-grade oil, 20 to 75% of food-grade white mineral oil, 10 to 50% of food-grade silicone oil and 5 to 30% of a tackifier. The beautifying agent provided by the invention can rapidly infiltrate into and fill in whitish scars on the outer surfaces of glass beer bottles due to repeated recycling, allows old bottles to turn into new bottles and to have good appearance, and has good bottle beautifying effect. According a formula in the invention, the active components of the beautifying agent are all food-grade and biodegradable, so the beautifying agent is free of toxicity, harm and pollution and friendly to environment.

Owner:刘书刚

A method of generating a two-dimensional code

ActiveCN106570550BImprove bindingImprove visual effectsRecord carriers used with machinesGraphicsComputer science

The invention belongs to the technical field of two-dimensional codes, and particularly relates to a method for generating a two-dimensional code. The method comprises the steps of (1) determining a functional pattern and a data region R(M)c of a two-dimensional code; (2) dividing the data region R(M)c into pixel matrixes according to black and white pixels of the data region R(M)c, and then calculating different rule patterns formed by the black pixels in the data region R(M)c by using a pattern judgment algorithm; and (3) replacing the different rule patterns with preset pictures. For a new propaganda link, a beautified two-dimensional code picture can be generated immediately according to the method, and the personnel cost and the production time loss of employing an art designer for a long term for realizing the similar effect are greatly saved. In addition, a two-dimensional code generated according to the method is good in anti-counterfeiting performance.

Owner:宁波邻家网络科技有限公司

Iron hoop bagging method for preventing peaches from dropping

PendingCN110810096AEnsure reproductive balanceEnsure normal growth and developmentPlant protective coveringsHorticultureBotany

The invention discloses an iron hoop bagging method for preventing peaches from dropping. The iron hoop bagging structure comprises a bag with a waterproof layer and an iron hoop, wherein the iron hoop is arranged in a fixing hole at one end of the bag with the waterproof layer. The dropped fruit iron hoop bagging ensures the reproductive growth balance of peach trees and the normal growth and development of the fruits, and avoids the occurrence of premature fruit dropping of peaches, improves the peach yield by more than 80%; and in addition, the peaches have large fruits, sufficient moistureand good mouthfeel, which are loved by the majority of consumers.

Owner:徐州鼎禾农业科技有限公司

A preparation method for reducing impurity sulfur in electrolytic nickel

ActiveCN103498169BImprove sulfur contentSulfur content can be controlledPhotography auxillary processesElectrolysis componentsElectrolysisVulcanization

The invention discloses a preparation method for reducing sulfur impurities in electrolytic nickel, belonging to the technical field of wet-process metallurgy. The preparation method comprises the following steps of casting nickel matte into an anode plate, and putting the anode plate in an electrolytic bath to perform vulcanization so as to directly electrolyze a nickel anode; taking a nickel starting sheet produced in a starting sheet cell as a cathode, and putting the cathode into a diaphragm bag; putting purified electrolyte into a cathode chamber, wherein the liquid level of the cathode chamber is higher than that of an anode chamber to ensure that an anode liquid can not enter the cathode chamber; electrifying in the electrolytic bath to generate electrolytic nickel; purifying the anode liquid, namely performing four-stage purification including copper removal through extraction, iron removal through oxidation neutralization, cobalt removal through extraction and sulfur reduction. The sulfur impurities in the electrolytic nickel generated through normal electrolysis is less than 0.001%, and the average content of the sulfur impurities is 0.0005%. According to the preparation method disclosed by the invention, a normal soluble anode is used as a template, and the content of the sulfur impurities in an electrolytic nickel plate is reduced by reducing the sulfur content in the cathode liquid, so that an electrolytic nickel finished product with extremely low content of the sulfur impurities is obtained. The process method is simple, and can effectively control the content of the sulfur impurities in the electrolytic nickel, and the obtained high-quality electrolytic nickel finished product can be widely applied.

Owner:JILIN JIEN NICKEL IND

Method for qualitatively detecting capillary cracks and segregation of steel used for piston pins

InactiveCN109283311AImprove applicabilityImprove recognitionTesting metal structuresAcid etchingTower

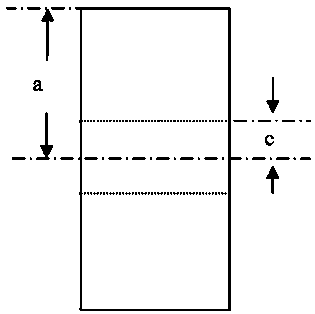

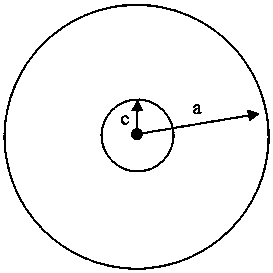

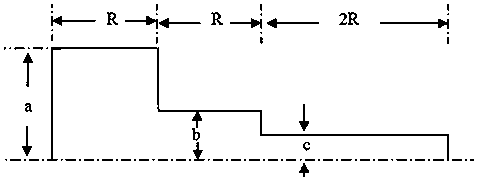

The invention discloses a method for qualitatively detecting capillary cracks and segregation of steel used for piston pins. The method comprises the following steps: processing a round steel sample to form a circular tower shape with three steps, wherein the sizes of formed stepped cylinders are that (1) in the first step, a processing radius is a and a length is R, (2) in the second step, a processing radius is b and a length is R, (3) in the third step, a processing radius is c and a length is 2R, a is the outer radius of the cylinder of a piston pin, c is equal to the radius of the inner bore of the piston pin multiplied by 90-100%, R is the radius of the round steel, and b is equal to 1 / 2(a+c); and subjecting the processed sample to surface acid etching, and then observing and examining the number, length and distribution of capillary cracks on the whole surface of each step. According to the invention, the outer working surface, the inner quality and the inner bore quality of thepiston pin are comprehensively reflected in a point-line-surface manner. The method of the invention improves detection efficiency, reduces detection cost, has the practical cost significance, and lays a foundation for the formulation of inspection standards of steel used for the piston pins.

Owner:HANDAN IRON & STEEL GROUP +1

Network marketing system and method

InactiveCN110276639AImprove output efficiencyRealize realizationAdvertisementsComputer terminalSmart network

The invention discloses a network marketing system and method. The system comprises a user terminal, a service terminal, a network server and a database. The network marketing method comprises the following steps: S1, a user actively participating in large-range popularization based on network marketing, S2, an intention user actively communicating with a customer service, S3, the user passively participating in large-range popularization based on artificial intelligence network marketing, and S4, the customer service actively communicating with the intention user. The method mainly aims at a network marketing system and method, and merchants can obtain wider and better propaganda effect through lower cost. Meanwhile, relying on a network platform, the system is popularized on the basis of a user terminal, a network server, a database based on big data and a service terminal, performs network marketing together with less manpower and artificial intelligence based on big data, and has the advantages of low implementation cost, high marketing efficiency, simplicity in operation and maintenance and the like.

Owner:WENZHOU POLYTECHNIC

Semi-rotation speed nuclear turbine final stage moving blade

ActiveCN102108883BImprove aerodynamicsReduce stressBlade accessoriesMachines/enginesEngineeringTurbine

The invention relates to a semi-rotation speed nuclear turbine final stage moving blade. A blade molded line is a variable cross-section torsion molded line. The semi-rotation speed nuclear turbine final stage moving blade has the following characteristic parameters: installation angle c1, chord length b1, maximum thickness w1, axial width Xa and sectional area A; a relative value of the height H of the blade increases monotonically from 0.1 to 1.0; an absolute value c1 of the installation angle decreases monotonically from 80.990 to 10.80; the variation principle of the relative value of the chord length b1 from a root sectional area to a top sectional area is that b1 is not greater than 1.557 and not less than 1.0; the variation principle of the relative value of the maximum thickness w1 from the root sectional area to the top sectional area is that w1 is not greater than 1.9465 and not less than 1.0; the variation principle of the relative value of the axial width Xa from the root sectional area to the top sectional area is that Xa is not greater than 8.387 and not less than 1.0; the variation principle of the relative value of the area A from the root sectional area to the top sectional area is that A is not greater than 5.553 and not less than 1.0; and the blade is composed by the lamination and smooth transition of 25 characteristic sections with different profiles and shapes along a blade height direction, wherein three of the characteristic sections are key sections: a section at 4.58% of H, a section at 51.00% of H, and a section at 96.99% of H, and the theory profile lines of the sections are described by the coordinates (X, Y) of 28 discrete points.

Owner:DONGFANG TURBINE CO LTD

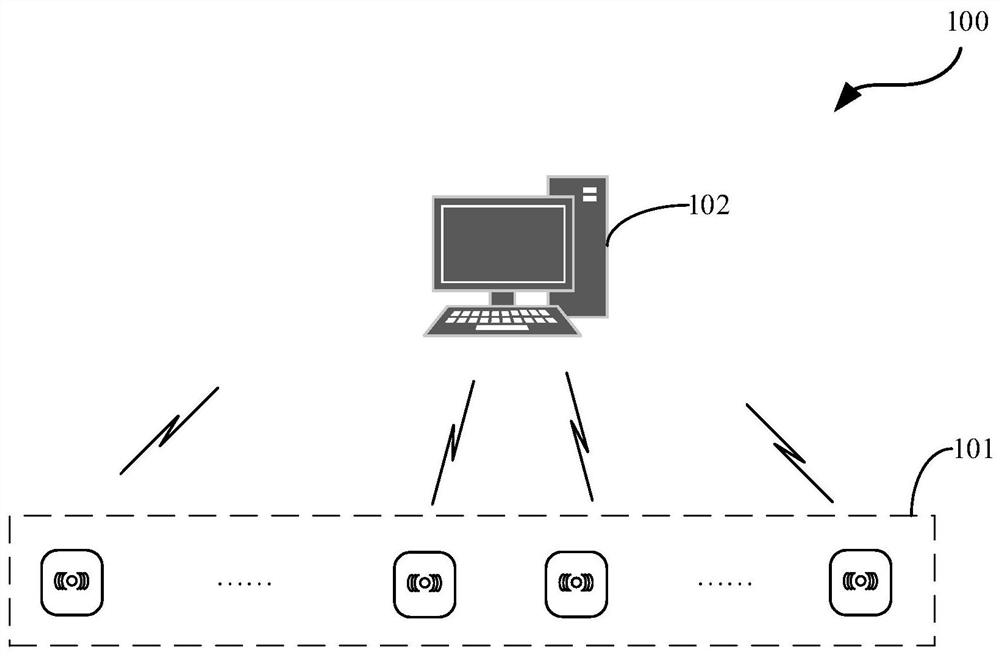

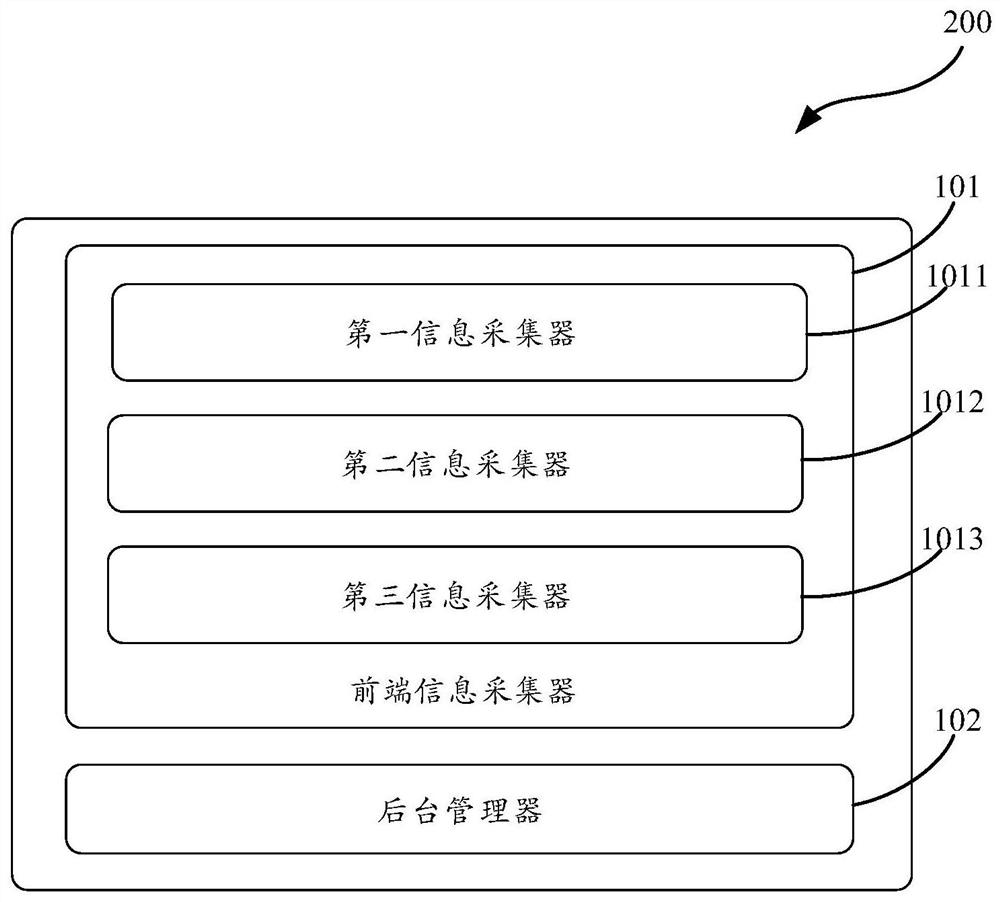

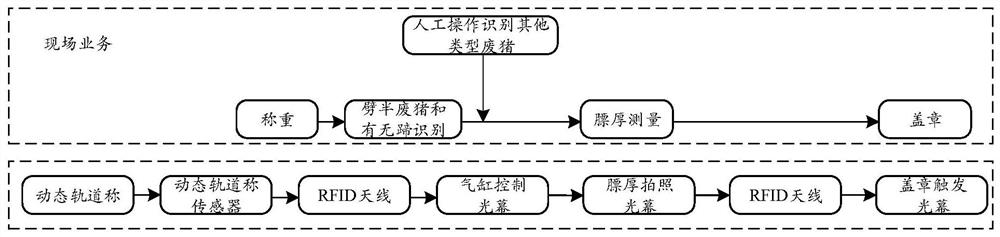

System for managing livestock carcass

PendingCN113988235AImprove management efficiencyHigh precisionCo-operative working arrangementsMeat/sausages markingAgricultural scienceData information

The invention relates to a system for managing a livestock carcass. The system comprises: a plurality of front-end information collectors, which are disposed at a plurality of positions on a carcass working track, and are configured to be used for collecting the working information of the carcass at different positions on the carcass working track, and outputting the collected working information; and a background manager, which is electrically connected with the plurality of front-end information collectors and is configured to perform point position complementation processing on the acquired operation information at different positions so as to generate traceable data information about the carcass. Through the above technical scheme of the invention, traceable management of the livestock carcass can be formed, and the management efficiency and the management precision of the livestock carcass are effectively improved.

Owner:牧原肉食品有限公司

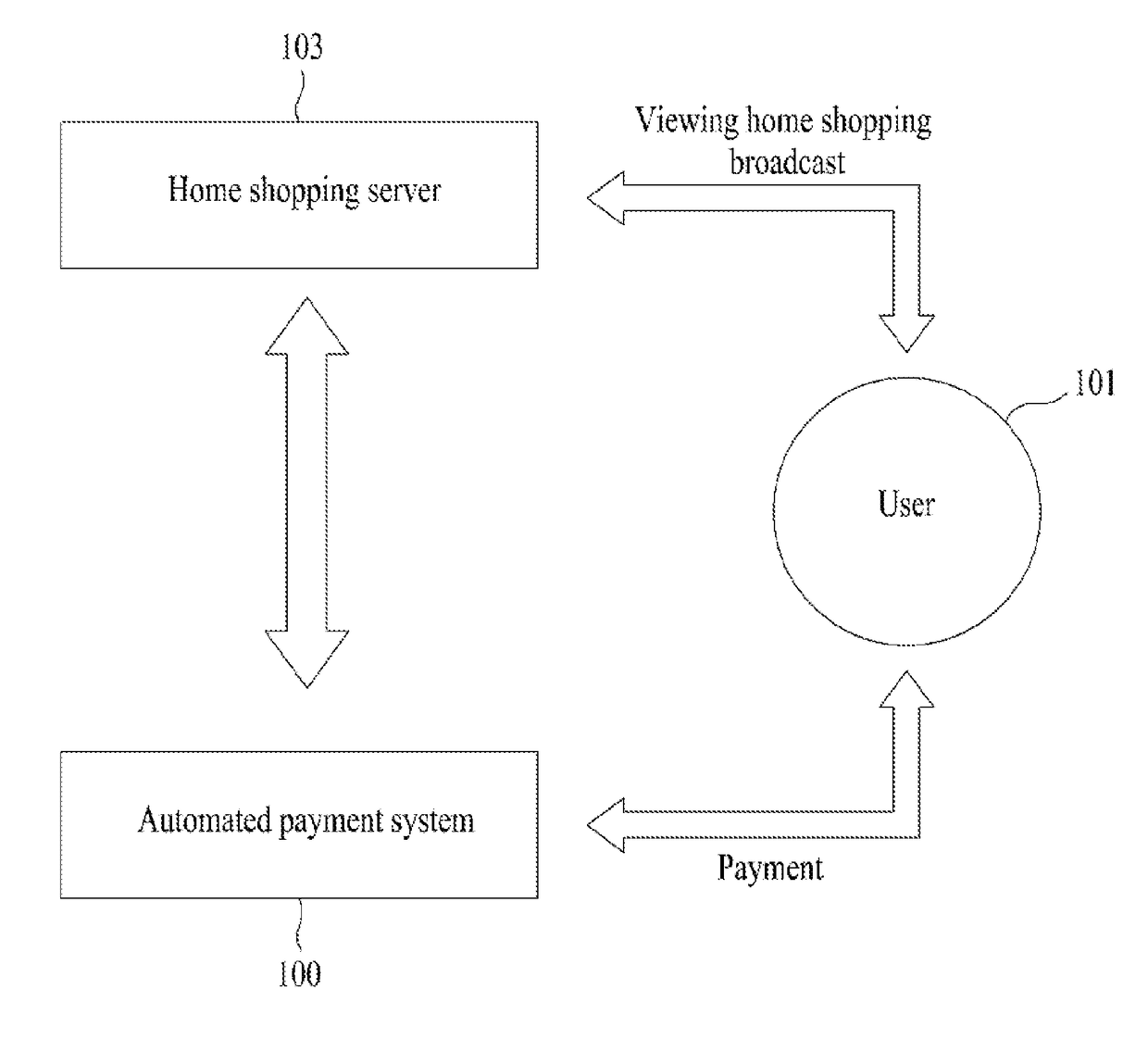

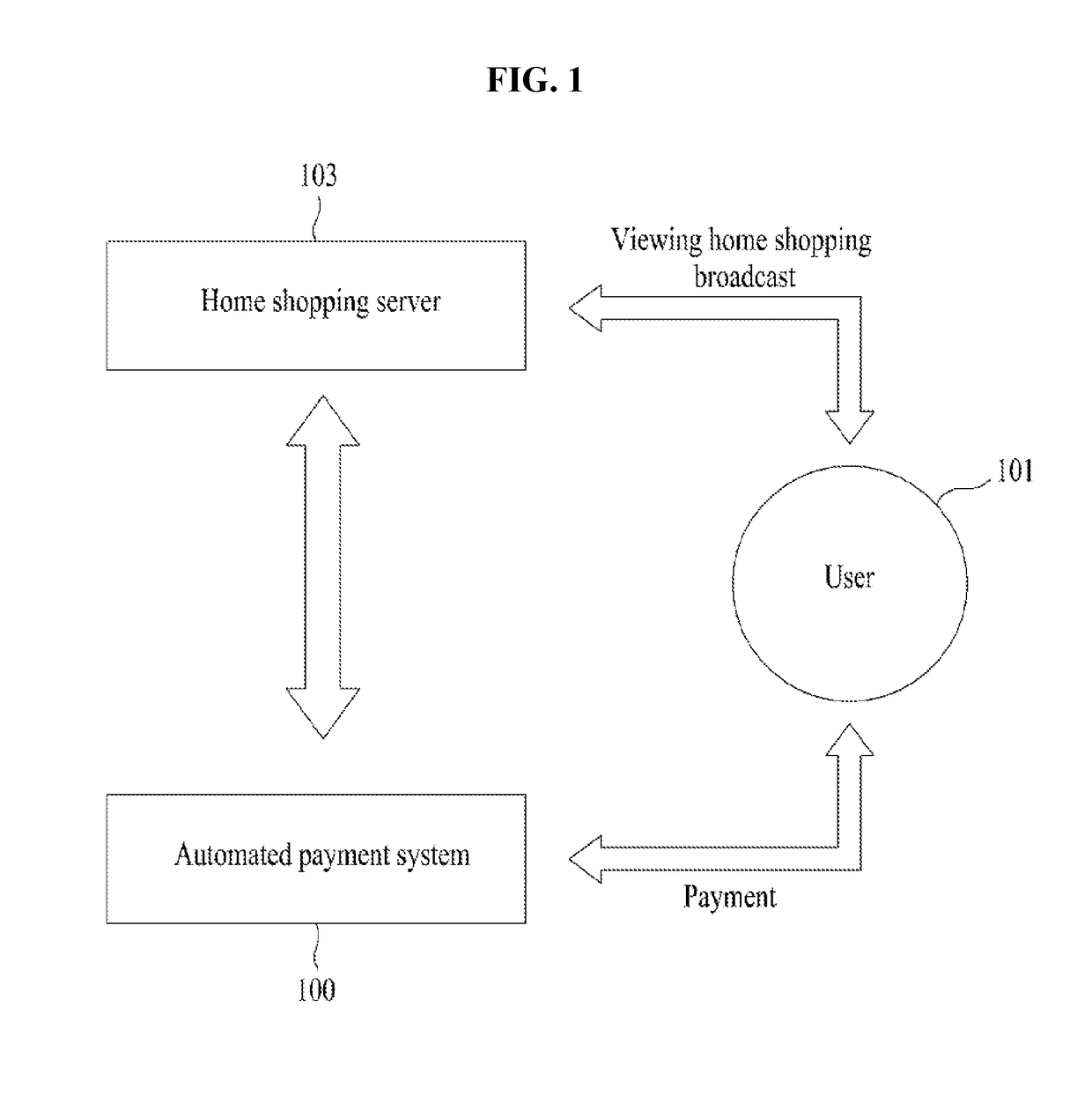

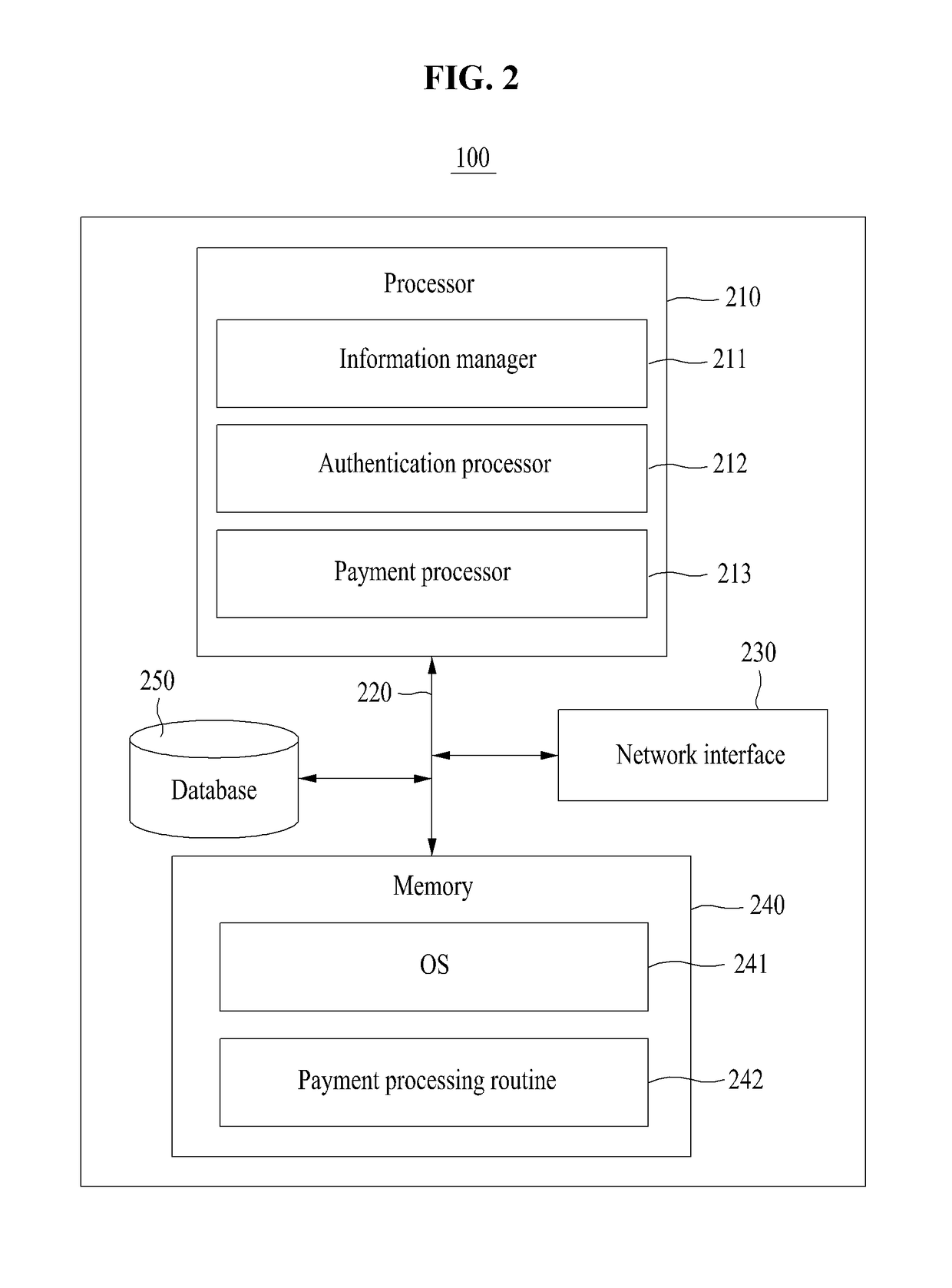

Method and system for providing automated payment

ActiveUS20170372309A1Shorten the timeMinimize troublesomenessBilling/invoicingPoint-of-sale network systemsBroadcastingComputer science

An automated payment method performed by an automated payment system include: receiving a payment request for a home shopping order from a user of a home shopping server associated with a home shopping broadcast; performing, in an authentication processor, authentication processing on the user based on a user information included in the payment request; and performing, in a payment processor, payment processing corresponding to the payment request based on the user information in response to successful authentication of the user.

Owner:NHN PAYCO CORP

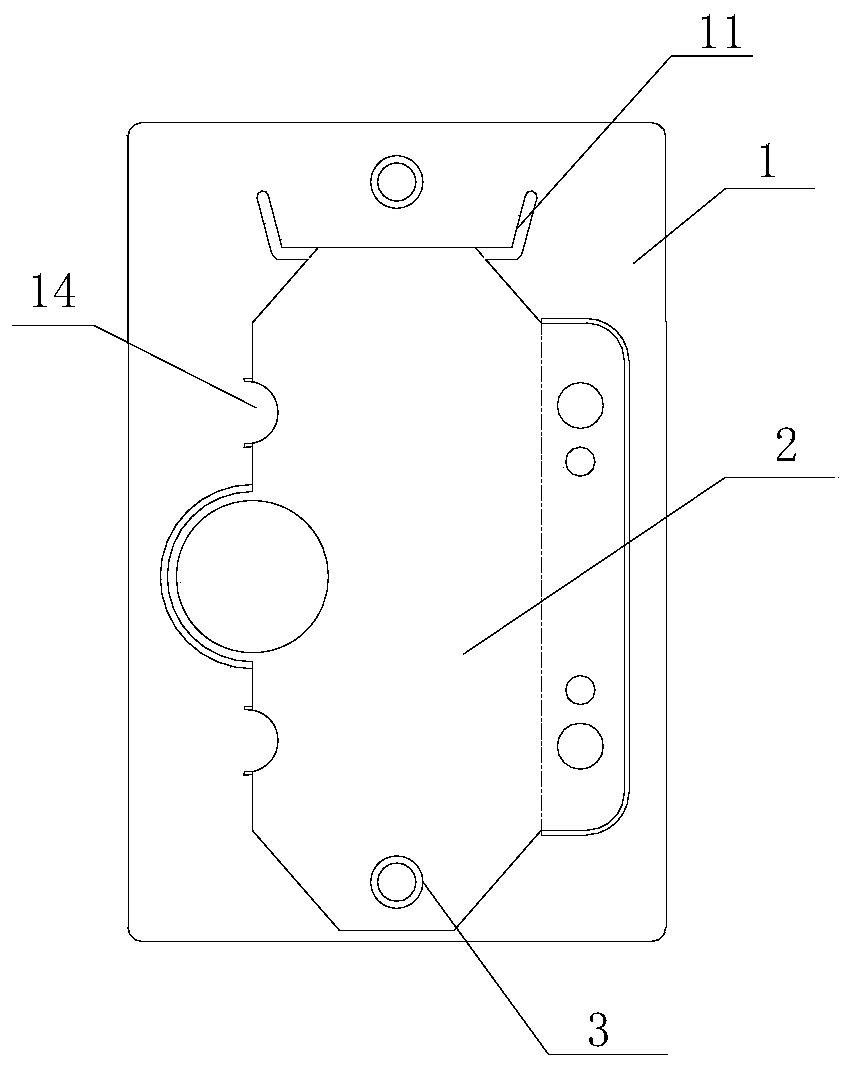

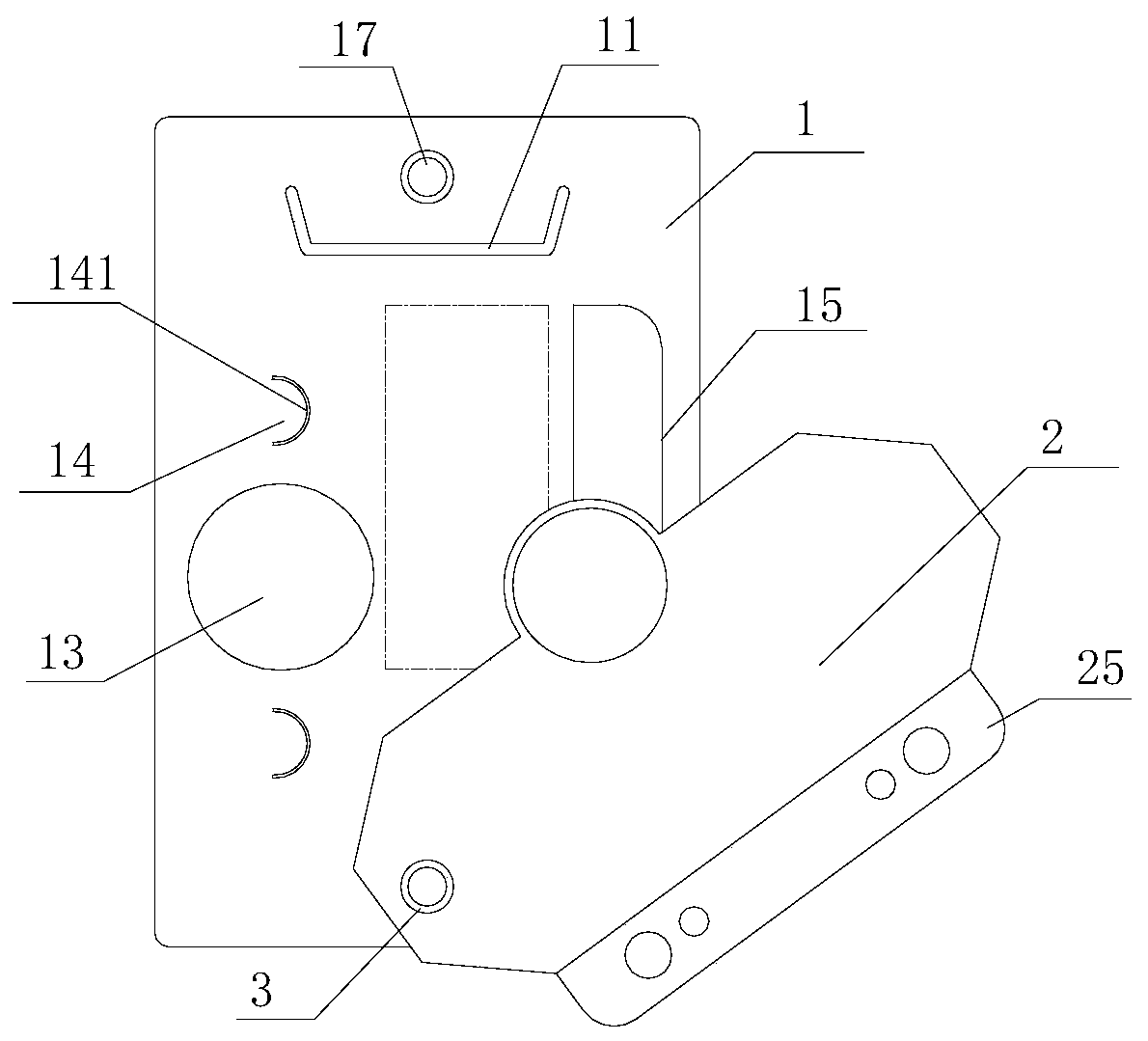

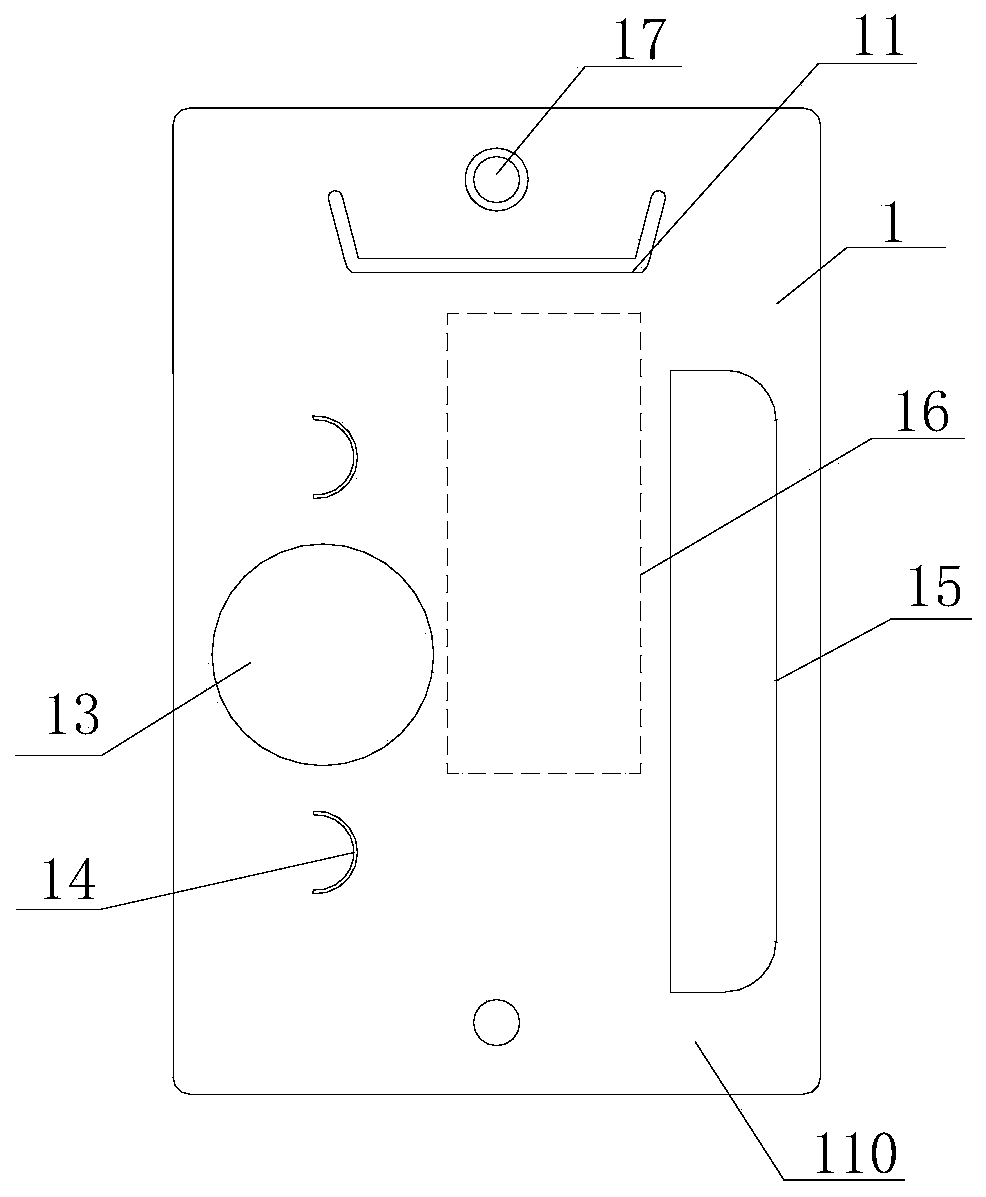

Leather-imitated hot stamping hollow embedded-type hanging tag

InactiveCN110277011AImprove aestheticsEnhance brand effectStampsIdentification meansCardboardHot stamping

The invention provides aleather-imitated hot stamping hollow embedded-type hanging tag. The leather-imitated hot stamping hollow embedded-type hanging tag includes a fixed paperboard, a movable paperboard and rivets, a hanging rope perforation is formed in the upper part of the fixed paperboard, the lower part of the fixed paperboard and the lower part of the movable paperboard are rotatably connected through the rivets, a U-shaped clamping groove is formed in the upper part of the fixed paperboard, the upper part of the movable paperboard is embedded with the U-shaped clamping groove, the fixed paperboard includes a metal-imitated dumb film decoration layer, a first paperboard basic layer and a leather-resistant bottom layer which are arranged successively from front to back, and the movable paperboard includes a leather-resistant decorative layer, a second paperboard basic layer and a metal-imitated light film base layer which are arranged successively from front to back. The movable paperboard capable of rotating is arranged on the fixed paperboard, and a logo of the text part on the fixed paperboard can be shielded to improve overall appearance of the tag; and an indicative pattern can be seen from the right side and the reverse side to improve the brand effect of the tag, a plurality of decorative hollow grooves are formed, and the entirety is stereoscopic and aesthetic.

Owner:HAIYAN XIMEI PRINTING

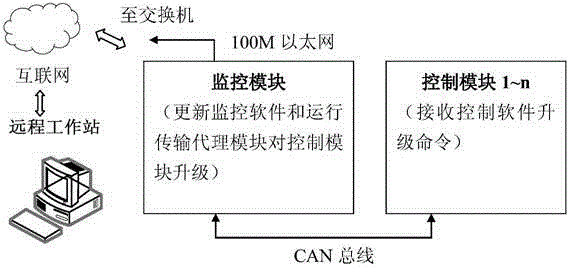

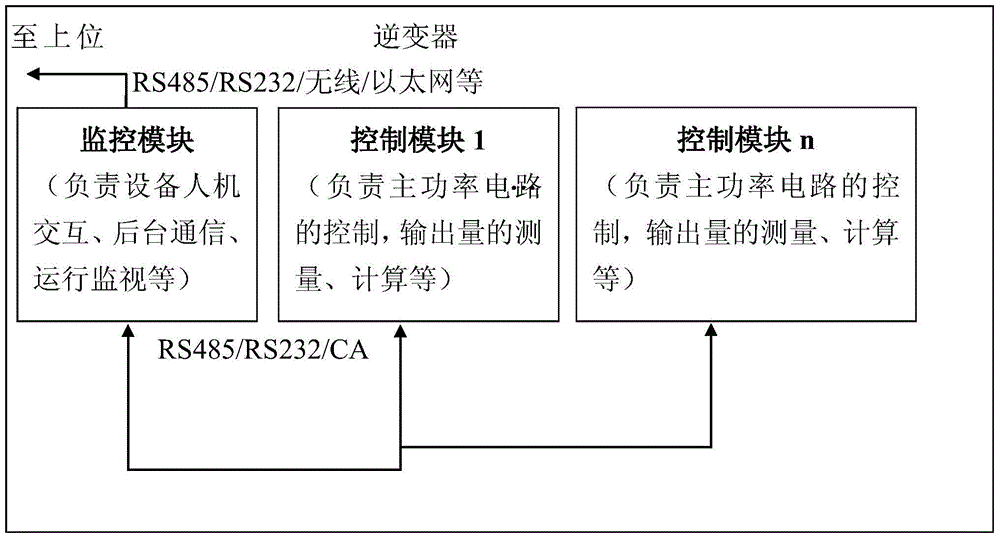

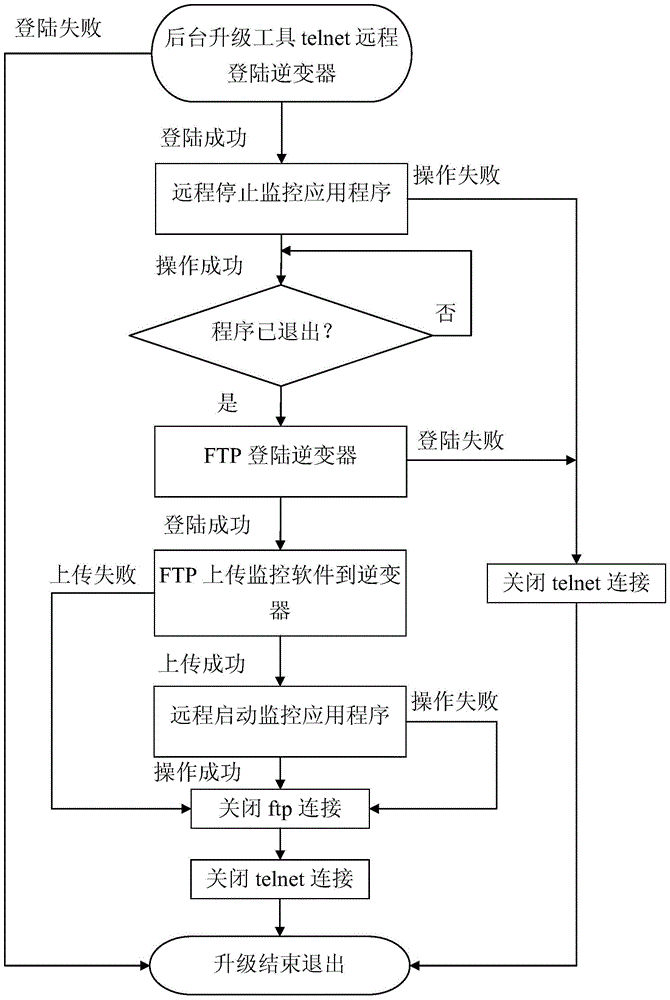

Method and system for upgrading software of photovoltaic inverter networked equipment

ActiveCN103580927BQuick responseReduce engineering costsProgram loading/initiatingData switching networksVirtualizationApplication software

The invention provides a photovoltaic inverter networked device software upgrading method and system. The photovoltaic inverter networked device software upgrading method includes the following steps: A1, enabling a background upgrading tool to log in an inverter in a long-distance mode, A2, stopping a monitoring application program in a long-distance mode, A3, judging whether a monitoring application program is already quitted or not, A4, logging in the inverter through an FTP, and executing a monitoring module software upgrading step or a control module software upgrading step if login is successfully achieved, otherwise, finishing the upgrading and quitting from the inverter. The photovoltaic inverter networked device software upgrading method and system have the advantages that device software can be updated in a long-distance mode, long-distance diagnosis services can be provided for clients in cooperation with a long-distance debugging tool, networking and virtualization of customer services are achieved, the response speed of the customer services is greatly quickened, the engineering cost is saved, and the brand effect of products is improved.

Owner:深圳市科士达软件科技有限公司

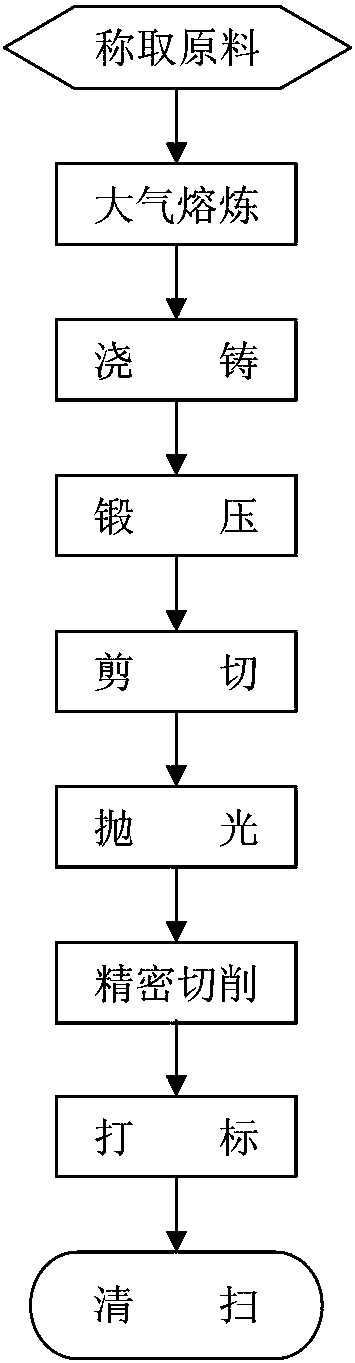

Preparation method for standard platinum with high purity

The invention relates to the technical field of preparation for standard platinum with high purity and in particular relates to a preparation method for standard platinum with high purity. The preparation method comprises the following steps of (A) weighing raw material, (B) melting in air, (C) casting, (D) forging, (E) shearing, (F) polishing, (G) cutting in a precise way, (H) marking and (I) cleaning. The production technology is simple and causes less loss; and the standard platinum with high purity has beautiful contour, and economic benefits can be improved.

Owner:GUIYAN RESOURCE YIMEN

A low-salt and variable-temperature pickling method for kohlrabi sauce products

The invention discloses a low-salt variable-temperature pickling method for a kohlrabi sauce product. The kohlrabi sauce product is prepared from the following raw and auxiliary materials in parts by weight: 280-300 parts of kohlrabi, 30-40 parts of green onion, 20-30 parts of garlic, Five-spice powder 15-25 parts, chili powder 10-20 parts, pepper powder 7-15 parts, oyster sauce 10-15 parts, vegetable oil 10-15 parts, salt 15-30 parts. The method adopts low-salt temperature-changing pickling and multi-strain coupling fermentation technology, adopts three times of temperature reduction and salt reduction, and two desalination methods can effectively reduce the salt content of pickled vegetables and shorten the pickling cycle; multi-strain coupling fermentation technology can be artificially controlled Multiple pure strains are mixed to make koji, which shortens the cycle and improves the quality and flavor. The kohlrabi sauce obtained is pure in color, low in salt and high in crispness, rich in essential amino acids and dietary fiber, unique in flavor and high in nutritional value.

Owner:HUBEI UNIV OF TECH

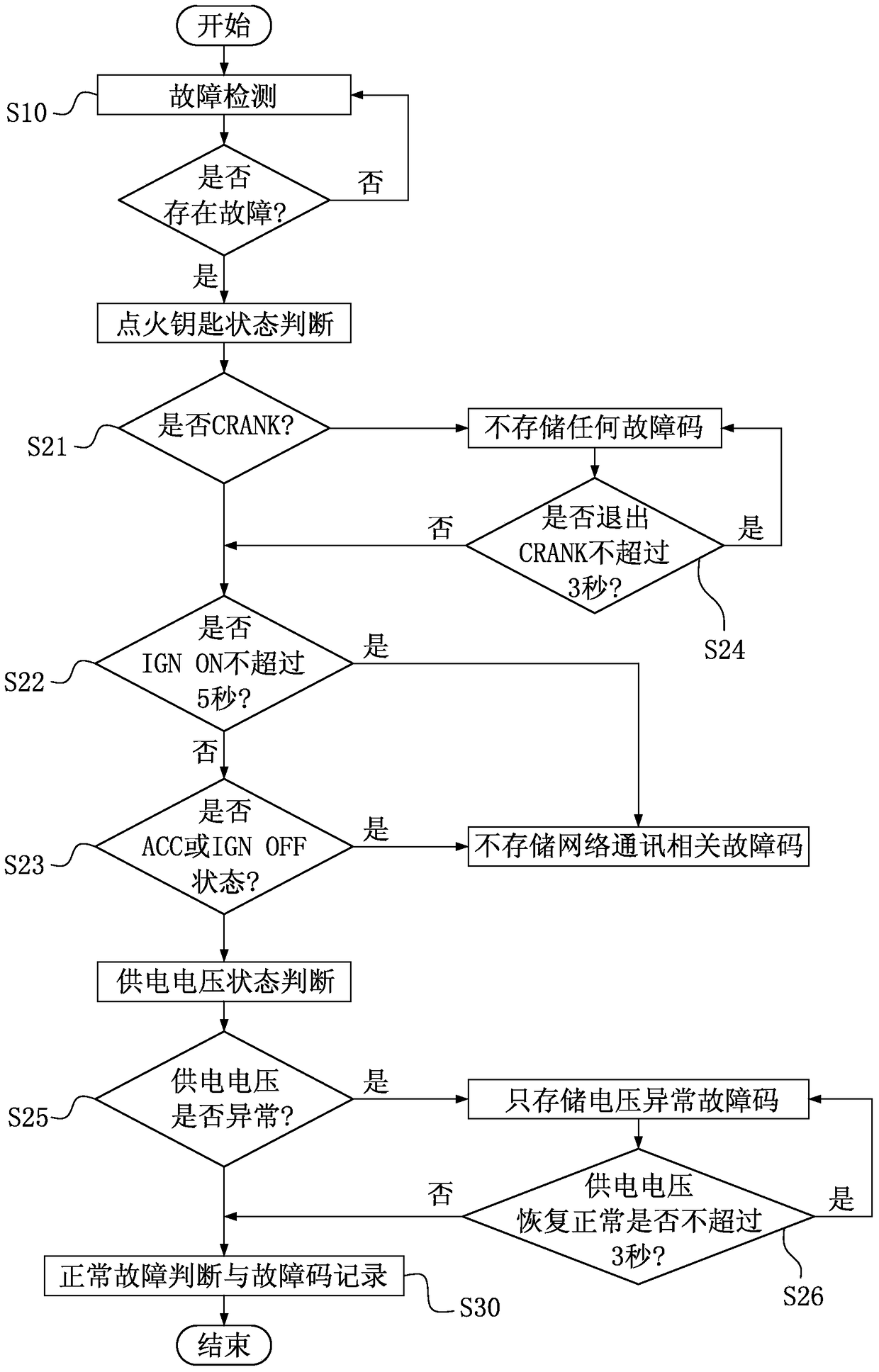

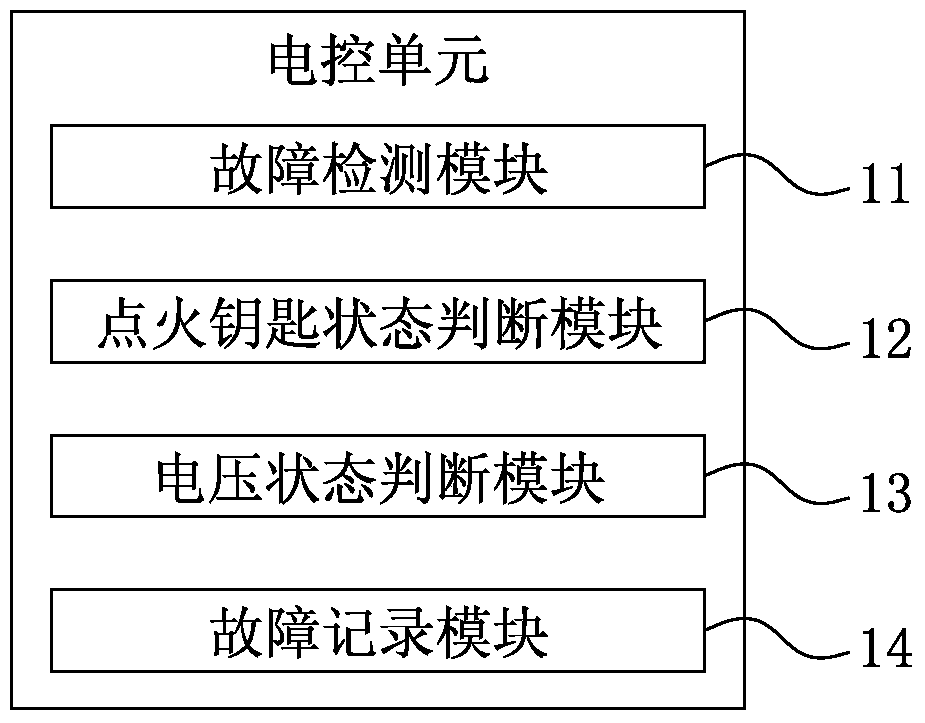

DTC detection and recording method of vehicle electronic control unit and vehicle electronic control unit

ActiveCN106557082BEnhance brand effectSolve the problem of false positivesElectric testing/monitoringNetwork communicationElectric control

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

A kind of steel for drilling pump air bag and its production method

The invention provides steel for an air chamber of a drilling pump and a production method of the steel. The steel comprises chemical components as follows: 0.29%-0.33% of C, 0.15%-0.35% of Si, 0.50%-0.60% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.95%-1.10% of Cr, 0.15%-0.25% of Ni, 0.15%-0.25% of Mo, 0.010%-0.025% of V, 0.015%-0.030% of Nb, 0.0060%-0.0100% of N, 0.018%-0.032% of Al and the balance iron and inevitable impurity elements. Compared with the prior art, by means of composition design of multi-element micro-alloying, forging waste heat isothermal annealing and heat treatment process optimization and on the premise of guaranteeing reliable quality of the air chamber, a normalizing procedure before quenched-tempered heat treatment is eliminated, the production cycle of the air chamber is shortened, and the heat treatment cost of users is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

Super-wear-resistant and high-elasticity vulcanized polyurethane cable sheath material and preparation method thereof

ActiveCN111518387AExtended service lifeEnhance brand effectPlastic/resin/waxes insulatorsPolyesterUv absorbance

The invention discloses a super-wear-resistant and high-elasticity vulcanized polyurethane cable sheath material. Raw materials involved in preparation of effective components comprise polyether typepolyurethane rubber, polyester type polyurethane rubber, an anti-aging agent MB, a flow dispersion auxiliary agent, ozone protection wax, sulfur, stearic acid, BIBP, a crosslinking auxiliary agent, aflame retardant, white carbon black, a coupling agent A172, titanium dioxide, temperature-resistant scarlet, an ultraviolet absorbent and an anti-hydrolysis agent. The cable sheath has excellent mechanical properties and wear resistance, the service life of a cable can be greatly prolonged, the enterprise brand effect is improved, and better economic benefits are brought to customers. Meanwhile, pollution emission of a cable manufacturing enterprise can be reduced due to the longer service life, and the requirements for energy conservation and environmental protection are met.

Owner:上海蓝昊电气江苏有限公司

A kind of super wear-resistant and highly elastic vulcanized polyurethane cable sheath material and its preparation method

ActiveCN111518387BExtended service lifeEnhance brand effectPlastic/resin/waxes insulatorsPolyesterVulcanization

The invention discloses a super wear-resistant and highly elastic vulcanized polyurethane cable sheath material. The raw materials and counterweight ratios involved in making the effective components are: polyether type polyurethane rubber, polyester type polyurethane rubber, anti-aging agent MB, Flow dispersion aid, ozone protection wax, sulfur, stearic acid, BIBP, cross-linking aid, flame retardant, silica, coupling agent A172, titanium dioxide, temperature-resistant bright red, ultraviolet absorber, anti-hydrolysis agent; The cable sheath has very excellent mechanical properties and wear resistance, which can greatly prolong the service life of the cable, enhance the brand effect of the enterprise, and bring better economic benefits to customers at the same time. At the same time, the longer service life can reduce the pollution discharge of cable manufacturing enterprises, which meets the requirements of energy saving and environmental protection.

Owner:上海蓝昊电气江苏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com