Preparation method for standard platinum with high purity

A high-purity and standard technology, applied in the field of preparation of high-purity standard platinum ingots, to achieve the effect of improving the overall image and public recognition, reducing losses, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

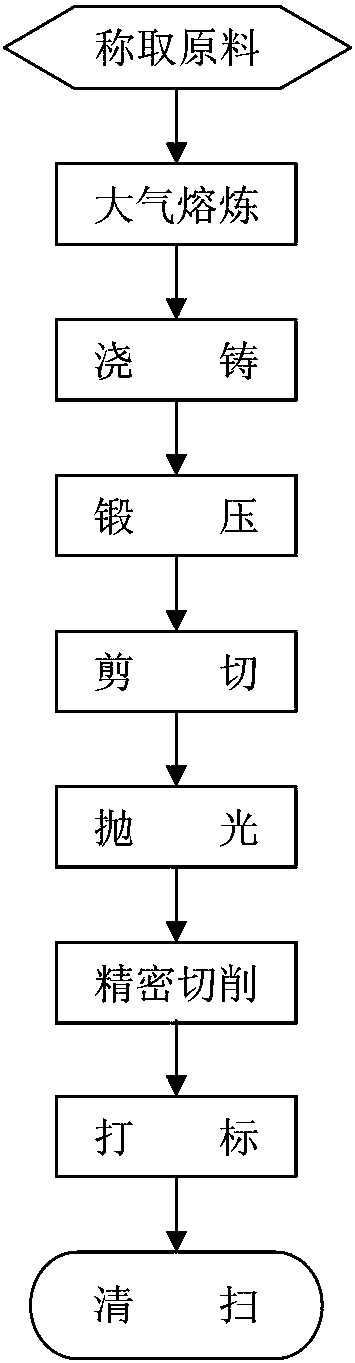

[0036] like figure 1 Shown, the preparation method of high-purity standard platinum ingot, carries out successively according to the following steps:

[0037] A, take raw material: high-purity platinum raw material is mainly high-purity platinum sponge powder, a small amount is high-purity platinum alloy scrap, raw material purity 99.96%; Take high-purity platinum raw material 1050 grams for subsequent use;

[0038] B. Atmospheric smelting: Add the high-purity platinum raw material weighed in step A into the quartz crucible of the intermediate frequency furnace, raise the temperature to 1850°C, and keep it warm for 30 minutes. The platinum smelting process is carried out in the atmosphere;

[0039] C. Casting: Use clamps to clamp out the quartz crucible that has reached the holding time in step B, and cast the molten platinum in a specially designed graphite mold. After the platinum solidifies, pour it out, and clamp the platinum ingot into cold water with clamps Cooling to o...

Embodiment 2

[0048] The preparation method of high-purity standard platinum ingot is carried out successively according to the following steps:

[0049] A, take raw material: high-purity platinum raw material is mainly high-purity platinum sponge powder, a small amount is high-purity platinum alloy scrap, raw material purity 99.97%; Take high-purity platinum raw material 1100 grams for subsequent use;

[0050] B. Atmospheric smelting: Add the high-purity platinum raw material weighed in step A into the quartz crucible of the intermediate frequency furnace, raise the temperature to 1950°C, and keep it warm for 25 minutes. The platinum smelting process is carried out in the atmosphere;

[0051] C. Casting: Use clamps to clamp out the quartz crucible that has reached the holding time in step B, and cast the molten platinum in a specially designed graphite mold. After the platinum solidifies, pour it out, and clamp the platinum ingot into cold water with clamps Cooling to obtain a rough billet...

Embodiment 3

[0060] The preparation method of high-purity standard platinum ingot is carried out successively according to the following steps:

[0061] A, Weigh raw material: high-purity platinum raw material is mainly high-purity platinum sponge powder, a small amount is high-purity platinum alloy scrap, raw material purity is greater than 99.99%; Take high-purity platinum raw material 1150 grams for subsequent use;

[0062] B. Atmospheric smelting: Add the high-purity platinum raw material weighed in step A into the quartz crucible of the intermediate frequency furnace, raise the temperature to 2000°C, and keep it warm for 20 minutes. The platinum smelting process is carried out in the atmosphere;

[0063] C. Casting: Use clamps to clamp out the quartz crucible that has reached the holding time in step B, and cast the molten platinum in a specially designed graphite mold. After the platinum solidifies, pour it out, and clamp the platinum ingot into cold water with clamps Cooling to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com