Wetting device for textile cloth

A technology for textile fabrics and textile fabrics, applied in the field of wetting devices for textile fabrics, which can solve problems such as increased production costs, production impacts, health hazards of employees, etc., and achieve the effects of ensuring cleanliness, easy collection, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

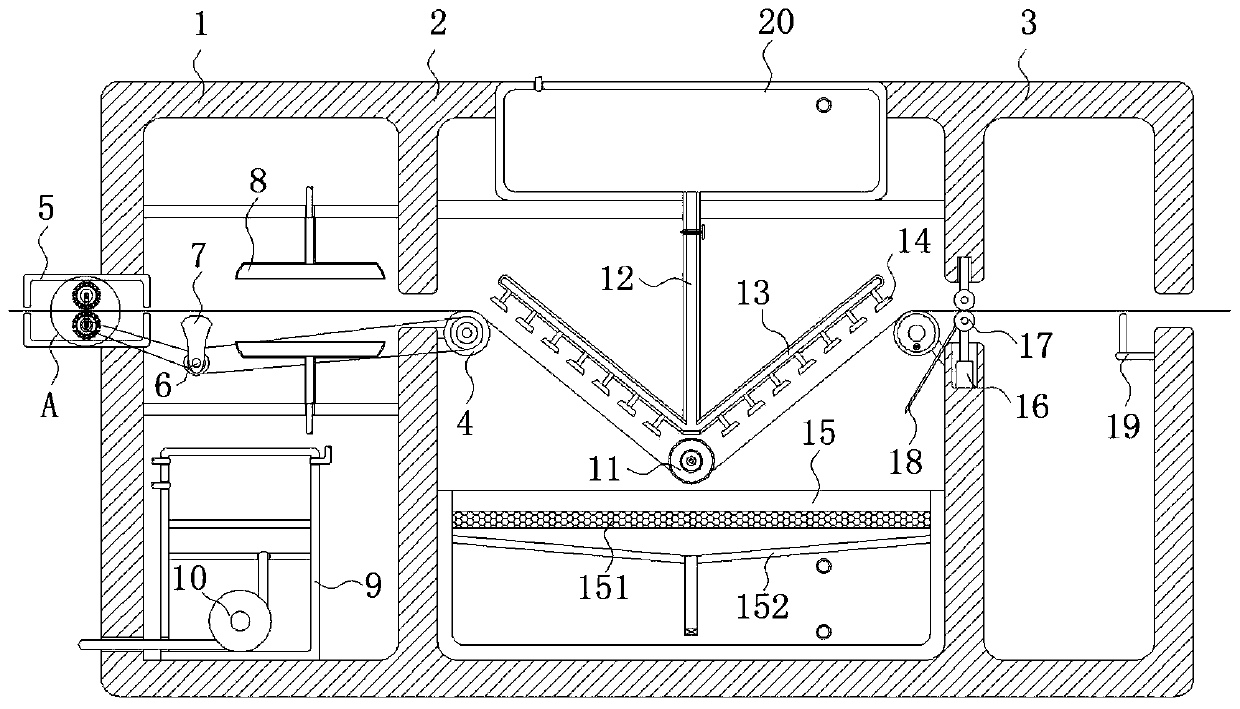

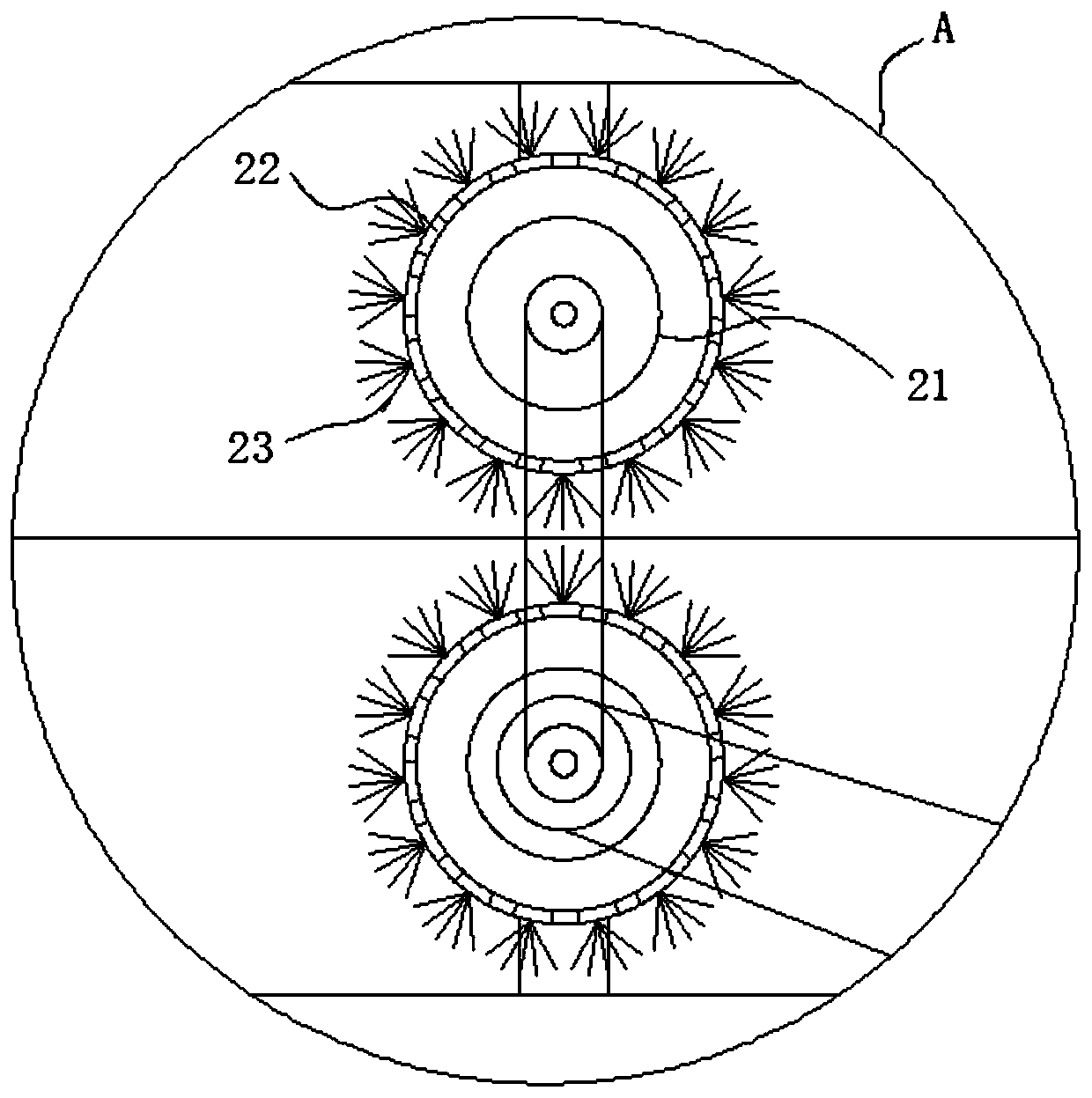

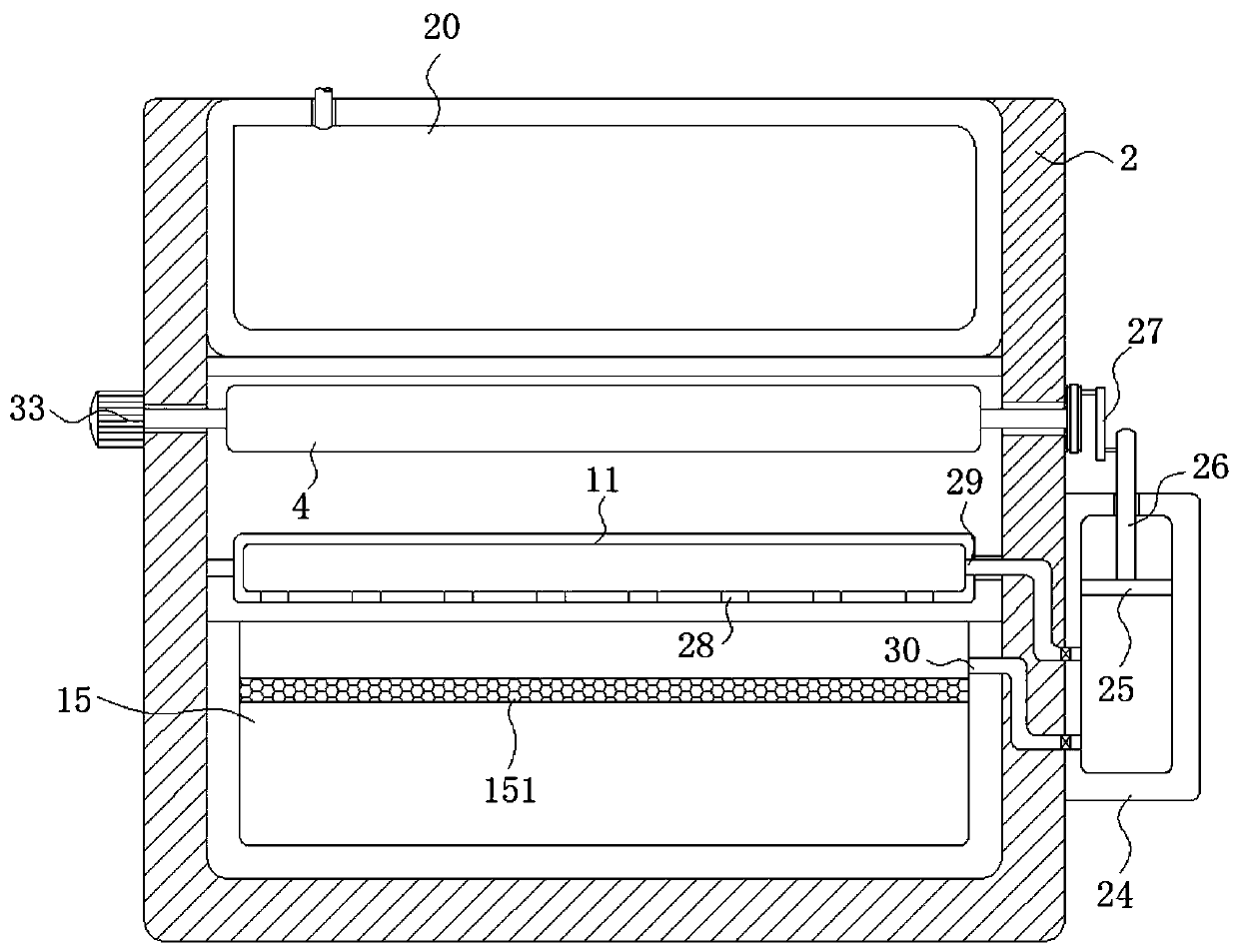

[0033] refer to Figure 1-4 , a wetting device for textile cloth, including a box body composed of a dust removal chamber 1, a humidification chamber 2 and a detection chamber 3, and the inner walls between two adjacent chambers are provided with frame openings for the passage of textile cloth, The inwall of detection chamber 3 is equipped with humidity detection device 19, and humidity detection device 19 is prior art, can determine whether the degree of humidity in the textile cloth meets the requirements, and the relative inwall of wetting chamber 2 is positioned at the lower side of frame mouth and is all rotatably connected with The outer wall of the roller 4 and the wetting chamber 2 is fixedly connected with a driving motor 33 for driving the rotation of the roller 4, and the relative inner wall of the wetting chamber 2 is fixedly connected with a water-absorbing cylinder 11, and the lower end of the water-absorbing cylinder 11 is evenly distributed with water-absorbing ...

Embodiment 2

[0042] refer to Figure 5 , different from Embodiment 1, the inner wall of the waste water collection tank 15 is located below the filter screen 151 and is provided with a conical plate 152. A one-way valve with water flowing from top to bottom. It should be noted that this one-way valve adopts the DIF-L10H1 type one-way valve. The opening pressure of this one-way valve is 0.04MPa, and the lower end of the hollow pipe is close to the waste water. The inner bottom of the collection tank 15 allows water to accumulate at the highest height on the hollow tube and the conical plate 152. From the pressure formula: p=ρgh, it can be seen that the vertical height of water accumulated on the one-way valve only needs to be greater than 0.4m. Just can make one-way valve open, thereby makes waste water flow in the waste water collecting tank 15 through one-way valve after being filtered, and the joint of vertical bar 26 and slide plug barrel 24 is provided with sealing ring, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com