Spore bulge imitating type filter plate for filtering gas suspended solid

A gas suspension and bulge-type technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and dispersed particle separation, can solve the problems of increased cleaning difficulty, influence of air filtration effect and efficiency, and increased workload, and can increase the area and range, increase the accommodation space, and improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

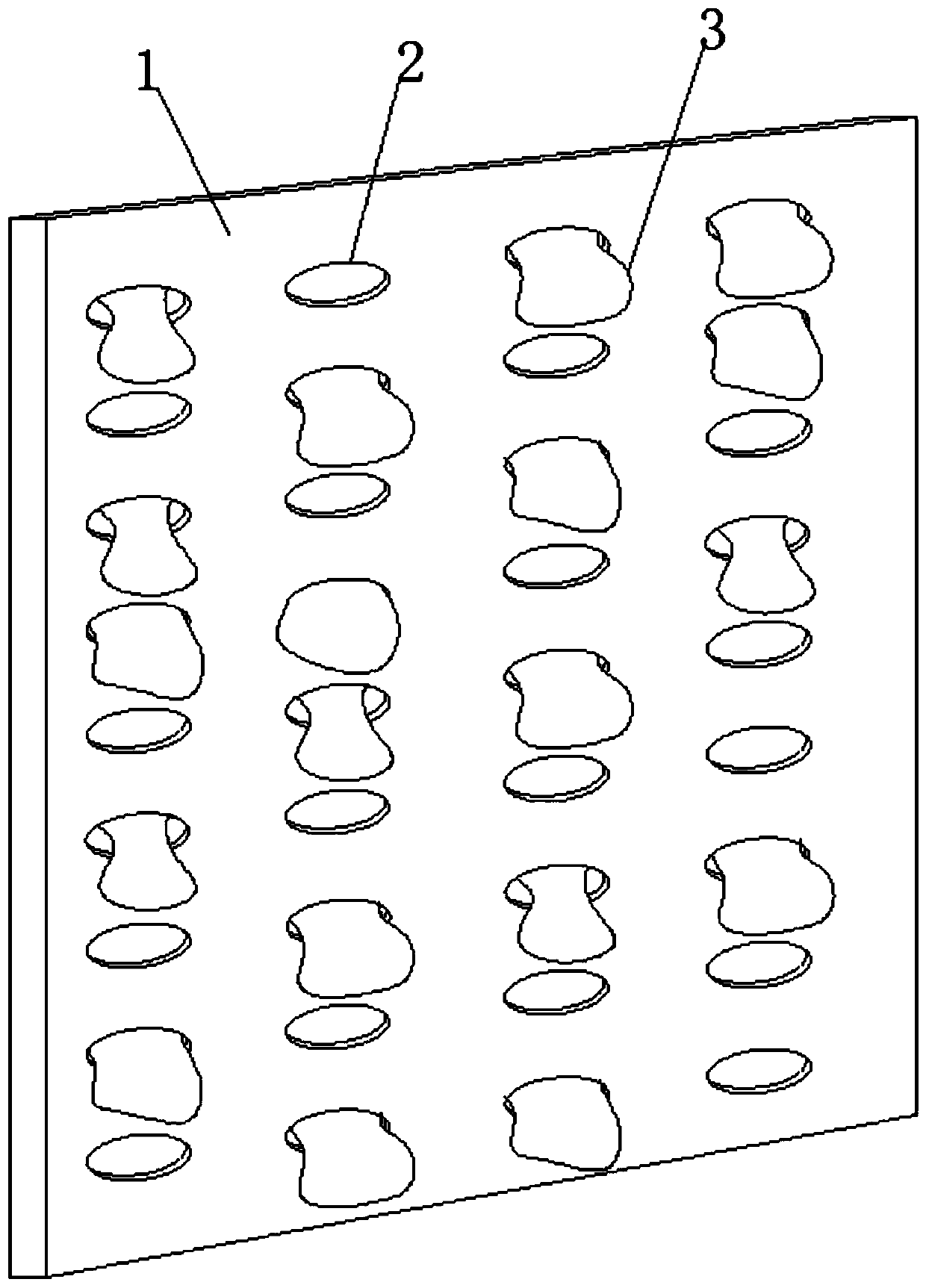

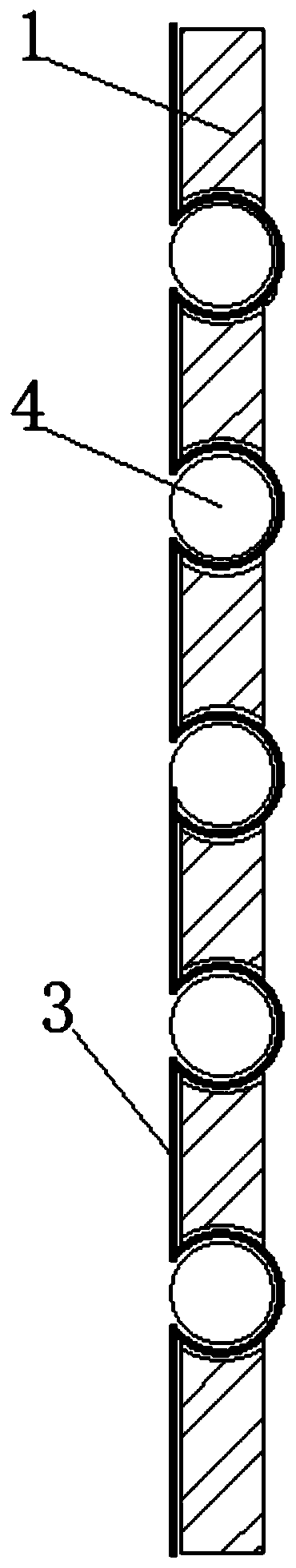

[0043] see Figure 1-2 , a spore-like bulging filter plate for filtering gas suspended solids, including a filter plate body 1, a plurality of spherical holes 2 are dug inside the filter plate body 1, and a power-assisted inlet ball 4 is placed in the spherical hole 2, and the filter plate body 1 includes One end is attached with an imitation spore filter cloth 3, the part of the imitation spore filter cloth 3 located at the spherical hole 2 is embedded in the spherical hole 2, and the imitation spore filter cloth 3 embedded in the spherical hole 2 is located on the inner wall of the spherical hole 2 and assists the inlet ball between 4.

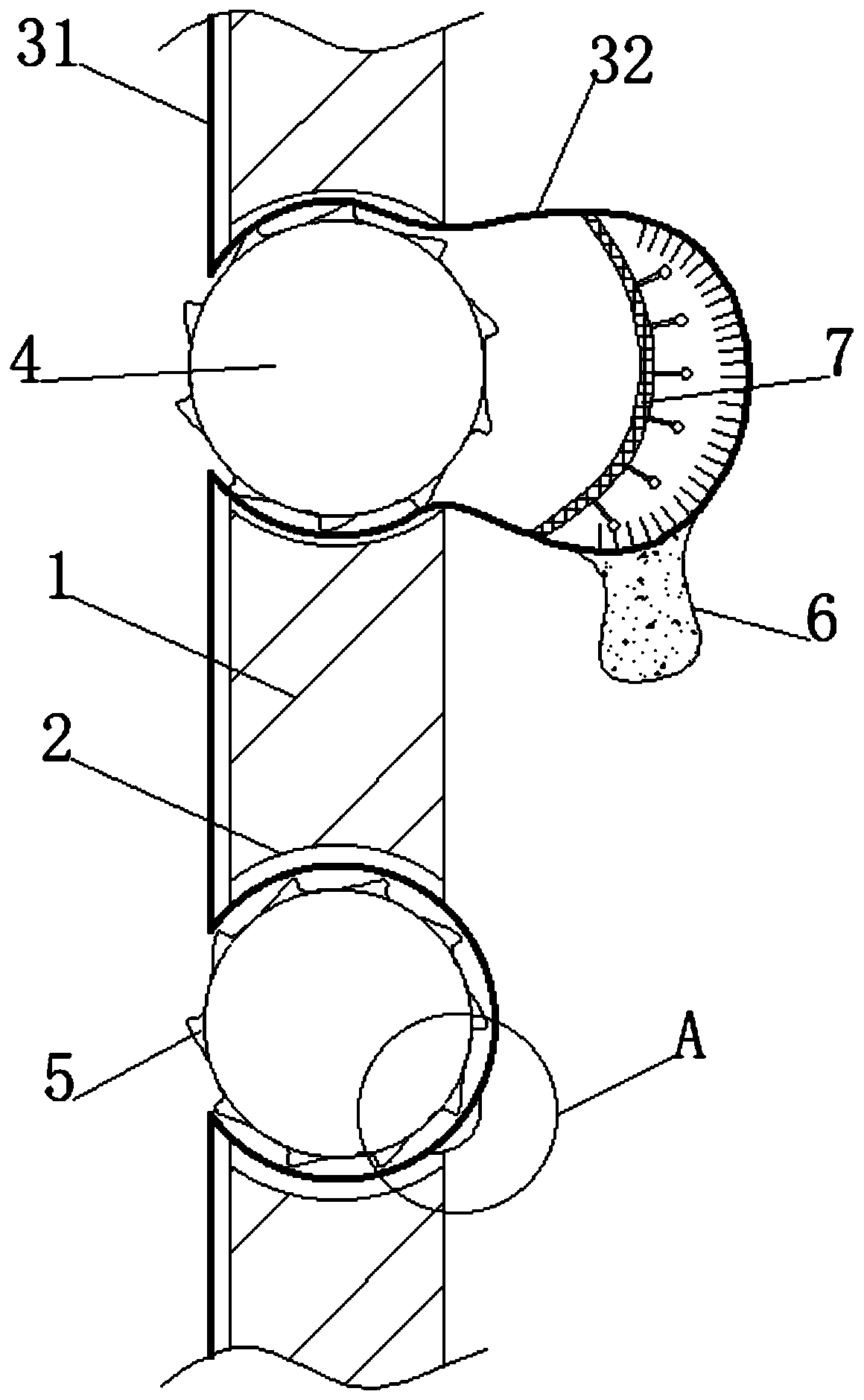

[0044] see image 3 The spore-like filter cloth 3 includes a positioning flat filter cloth 31 and a plurality of spore-type filter capsules 32, the positioning flat filter cloth 31 and a plurality of spore-type filter capsules 32 are integrated, and the spore-type filter capsule 32 is located in the spherical hole 2, The positioning flat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com