Deep hole machining magnetorheological liquid flutter suppressing device

A technology of magnetorheological fluid and suppression device, which is used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of difficulty in suppressing chatter vibration, improve the suppression speed, facilitate installation and maintenance, and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

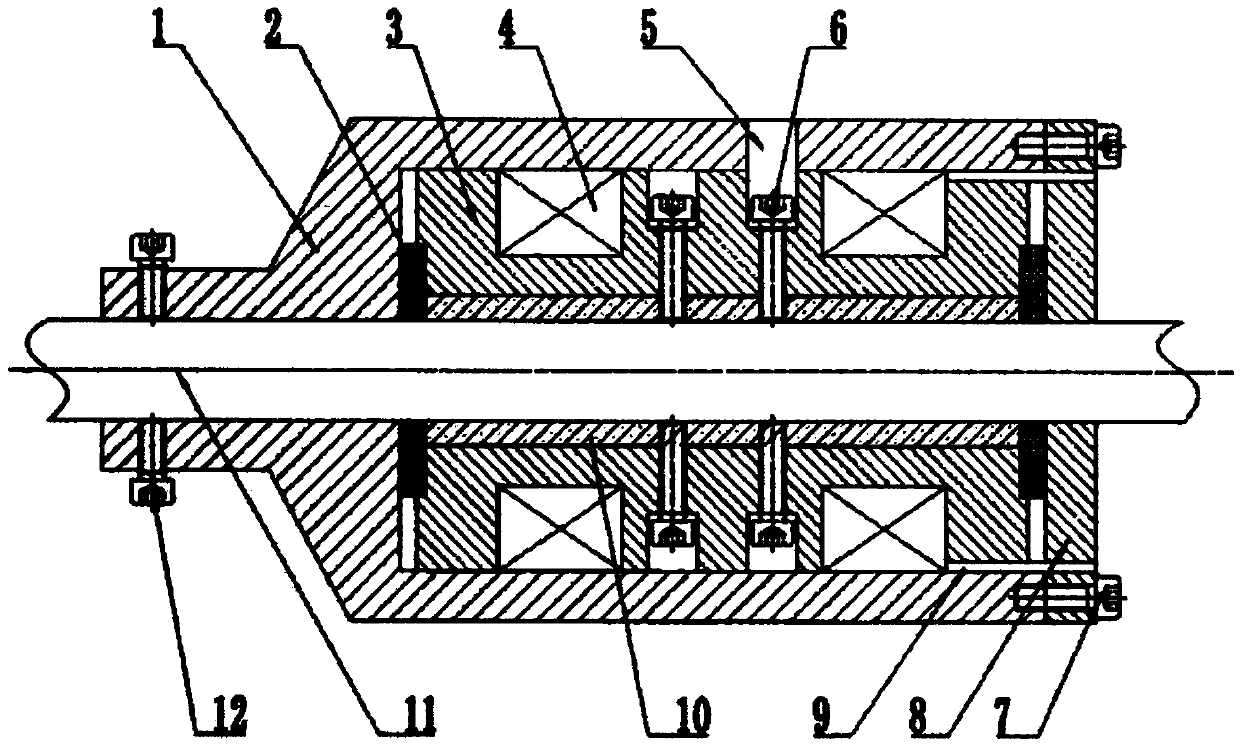

[0019] Such as figure 1 A magneto-rheological fluid chatter suppressing device for deep hole machining is shown, comprising: a support sleeve 1, an electromagnetic generating mechanism, an end cover 8 and a magnetorheological fluid material 10, the electromagnetic generating mechanism is arranged in the support sleeve 1, The electromagnetic generating mechanism includes: an electromagnetic coil 4 and a hollow electromagnet core 3, and the hollow electromagnet core 3 has 2 annular recesses, the electromagnetic coil 4 is wound in the recess, and the hollow electromagnet core 3 There are also two groups of through holes symmetrically opened in the middle, each group of through holes includes two injection holes 5, the injection holes 5 are tapped with internal threads, and the middle part of the end cover 8 is provided with through holes corresponding to the workpiece. The rear end of the support sleeve 1 is bolted to the end cover 8 . The two ends of the hollow electromagnet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com