Slow virus carrier fluid sterile sorting method and sorting system

A technology of lentiviral carrier and dispensing system, which is applied in the field of lentiviral carrier liquid aseptic dispensing method and dispensing system, which can solve the problems of inability to use automatic dispensing of the production line, high requirements for packaging tubes, and long sterilization time, etc. To achieve the effect of reducing product packaging time, reducing storage time, and not easy to pollute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

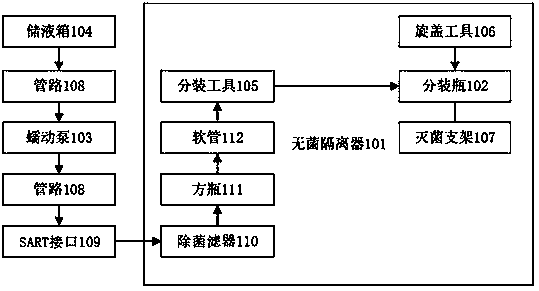

[0039] Second embodiment, such as figure 1 As shown, a lentiviral carrier liquid aseptic packaging system of the present invention includes a sterile isolator 101, a filling bottle 102, and a feeding assembly. The interior of the sterile isolator 101 is provided with a packaging tool 105, a rotary The capping tool 106 and the sterilization support 107 for placing the sub-bottle 102, the capping tool 106 is arranged on the upper side of the sterilization support 107, the feeding assembly communicates with the SART interface 109 on the aseptic isolator 101, and the aseptic isolator 101 A sterilizing filter 110 communicating with the SART interface 109 is provided inside, a square bottle 111 is connected to the other end of the sterilizing filter 110 , and a hose 112 communicating with the square bottle 111 is connected on the dispensing tool 105 .

[0040] In the aseptic dispensing system for lentiviral carrier liquid provided in this embodiment, the dispensing tool 105 used is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com