A kind of brown vat dye taking naphthalene tetracarboxylic acid as raw material, preparation method and application

A technology of naphthalene tetracarboxylic acid and dyes, which is applied in the field of preparation of naphthalene tetracarboxylic acid vat dyes, which can solve the problems of failing to meet customer requirements and large color difference of dyes, and achieve the effects of reducing the discharge of three wastes, moderate color power, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

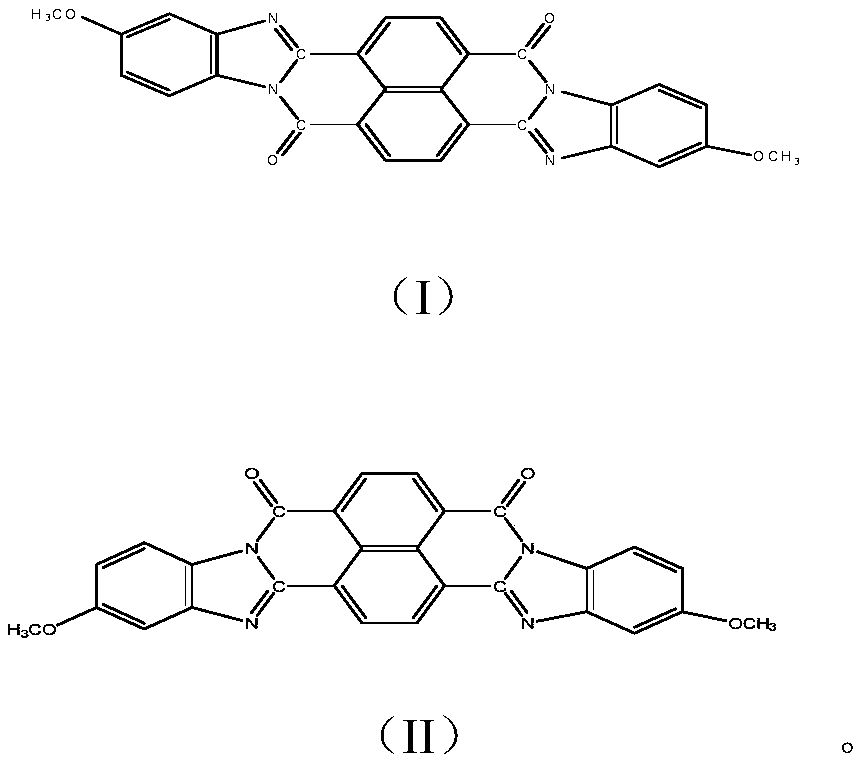

[0040] A brown vat dye using naphthalene tetracarboxylic acid as a raw material, including two compounds shown in the following formulas (I) and (II):

[0041]

[0042] The preparation method of described brown vat dye comprises the steps:

[0043] Add 65 parts of water into the reaction vessel, add 9 parts of glacial acetic acid as a catalyst under stirring, the volume concentration of acetic acid in the system is 12.2%, then add 9 parts of 1,4,5,8-naphthalene tetracarboxylic acid and 10 parts of 4-formaldehyde Oxygen-1,2-o-phenylenediamine, closed reactor, heating up to 134°C, pressure 0.2MPa, heat preservation and pressure stirring for 6 hours, cooling down to 80°C, filtering while hot, and then using 90°C hot water to decompose the filter cake Washing to neutrality, the filter cake was dried and pulverized to obtain 16 parts of reddish-brown powder; wherein, the mass ratio of 1,4,5,8-naphthalene tetracarboxylic acid and 4-methoxy-1,2-o-phenylenediamine for 9:10.

[00...

Embodiment 2

[0053] A brown vat dye using naphthalene tetracarboxylic acid as a raw material, which includes compounds shown in the following formulas (I) and (II):

[0054]

[0055]

[0056] The preparation method of described brown vat dye comprises the steps:

[0057] Add 65 parts of water into the reaction vessel, add 9 parts of glacial acetic acid as a catalyst under stirring, the volume concentration of acetic acid in the system is 12.2%, then add 9 parts of 1,4,5,8-naphthalene tetracarboxylic acid and 9 parts of 4-formaldehyde Oxygen-1,2-o-phenylenediamine, closed reactor, heating up to 134°C, pressure 0.2MPa, heat preservation and pressure stirring for 6 hours, cooling down to 80°C, filtering while hot, and then using 90°C hot water to decompose the filter cake Washing to neutrality, the filter cake was dried and pulverized to obtain 16 parts of reddish-brown powder; wherein, the mass ratio of 1,4,5,8-naphthalene tetracarboxylic acid and 4-methoxy-1,2-o-phenylenediamine It i...

Embodiment 3

[0060] A brown vat dye using naphthalene tetracarboxylic acid as a raw material, which includes compounds shown in the following formulas (I) and (II):

[0061]

[0062] The preparation method of described brown vat dye comprises the steps:

[0063] Add 65 parts of water into the reaction vessel, add 9 parts of glacial acetic acid as a catalyst under stirring, the volume concentration of acetic acid in the system is 12.2%, then add 9 parts of 1,4,5,8-naphthalene tetracarboxylic acid and 10 parts of 4-formaldehyde Oxygen-1,2-o-phenylenediamine, closed reactor, temperature raised to 134°C, pressure 1.0MPa, heat preservation and pressure stirring for 6 hours, cooling to 80°C, filtering while hot, and then using 90°C hot water to filter cake Washing to neutrality, the filter cake was dried and pulverized to obtain 16 parts of reddish-brown powder; wherein, the mass ratio of 1,4,5,8-naphthalene tetracarboxylic acid and 4-methoxy-1,2-o-phenylenediamine for 9:10.

[0064] The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com