Adhesive for beer bottle label clip printing automatic glue spraying system and preparation method

A beer bottle and adhesive technology, which is applied in the direction of adhesive types, starch adhesives, unsaturated alcohol copolymer adhesives, etc., can solve the problems of label "stamp printing, bubbling and wrinkles, etc., and achieve Improved stability, strong adhesion, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

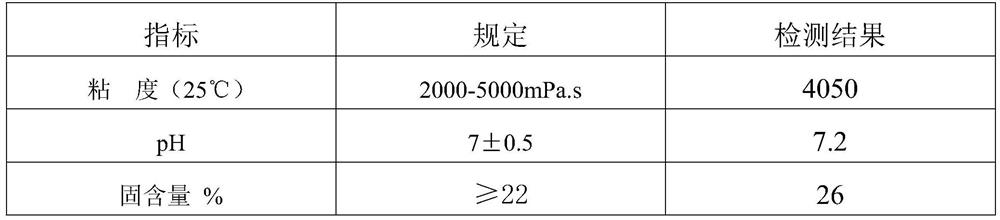

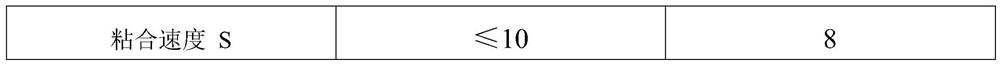

Examples

Embodiment 1

[0021] This embodiment provides an adhesive for an automatic glue spraying system for beer bottle label clamp printing, which is made of the following raw materials in parts by weight: 80 parts of polyvinyl alcohol with a degree of polymerization of 1700, and 250 parts of white dextrin , 35 parts of urea, 8 parts of zinc chloride, 3 parts of white mineral oil defoamer, 2 parts of Kason, 8 parts of ammonia water, and 480 parts of water.

[0022] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0023] a. Add water to the reaction kettle, then add polyvinyl alcohol and white mineral oil defoamer in turn, stir evenly, heat up to 85°C, and keep warm for 1 hour;

[0024] b. Cool down to below 50°C, then add white dextrin, urea, zinc chloride, and Cathone in turn, and continue stirring for 2 hours;

[0025] c, adjust the pH value to 7.0 by adding ammonia water;

[002...

Embodiment 2

[0030] This embodiment provides an adhesive for an automatic glue spraying system for beer bottle label clamp printing, which is made of the following raw materials in parts by weight: 50 parts of polyvinyl alcohol with a degree of polymerization of 1700, and 300 parts of white dextrin , 20 parts of urea, 10 parts of zinc chloride, 2 parts of silicone defoamer, 4 parts of Kathon, 5 parts of ammonia, and 500 parts of water.

[0031] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0032] a. Add water into the reaction kettle, then add polyvinyl alcohol and white mineral oil defoamer in turn, stir evenly, heat up to 80°C, and keep warm for 1 hour;

[0033] b. Cool down to below 50°C, then add white dextrin, urea, zinc chloride, and Cathone in turn, and continue stirring for 2 hours;

[0034] c, adjust the pH value to 7.1 by adding ammonia water;

[0035] d. Accor...

Embodiment 3

[0039] This embodiment provides an adhesive for an automatic glue spraying system for beer bottle label clamp printing, which is made of the following raw materials in parts by weight: 100 parts of polyvinyl alcohol with a degree of polymerization of 1700, and 200 parts of white dextrin , 50 parts of urea, 5 parts of zinc acetate, 4 parts of silicone defoamer, 1 part of Kathon, 10 parts of ammonia water, and 500 parts of water.

[0040] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0041] a. Add water into the reaction kettle, then add polyvinyl alcohol and white mineral oil defoamer in turn, stir evenly, heat up to 90°C, and keep warm for 1 hour;

[0042] b. Cool down to below 50°C, then add white dextrin, urea, zinc acetate, and Cathone in turn, and continue stirring for 2 hours;

[0043] c, adjust the pH value to 7.2 by adding ammonia water;

[0044] d. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com