Continuous automatic manufacturing process for T-shaped steel purlin supporting sheet

A manufacturing process and purlin supporting plate technology, applied in the field of steel structure manufacturing, can solve problems affecting building stability, hidden safety hazards, and large material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

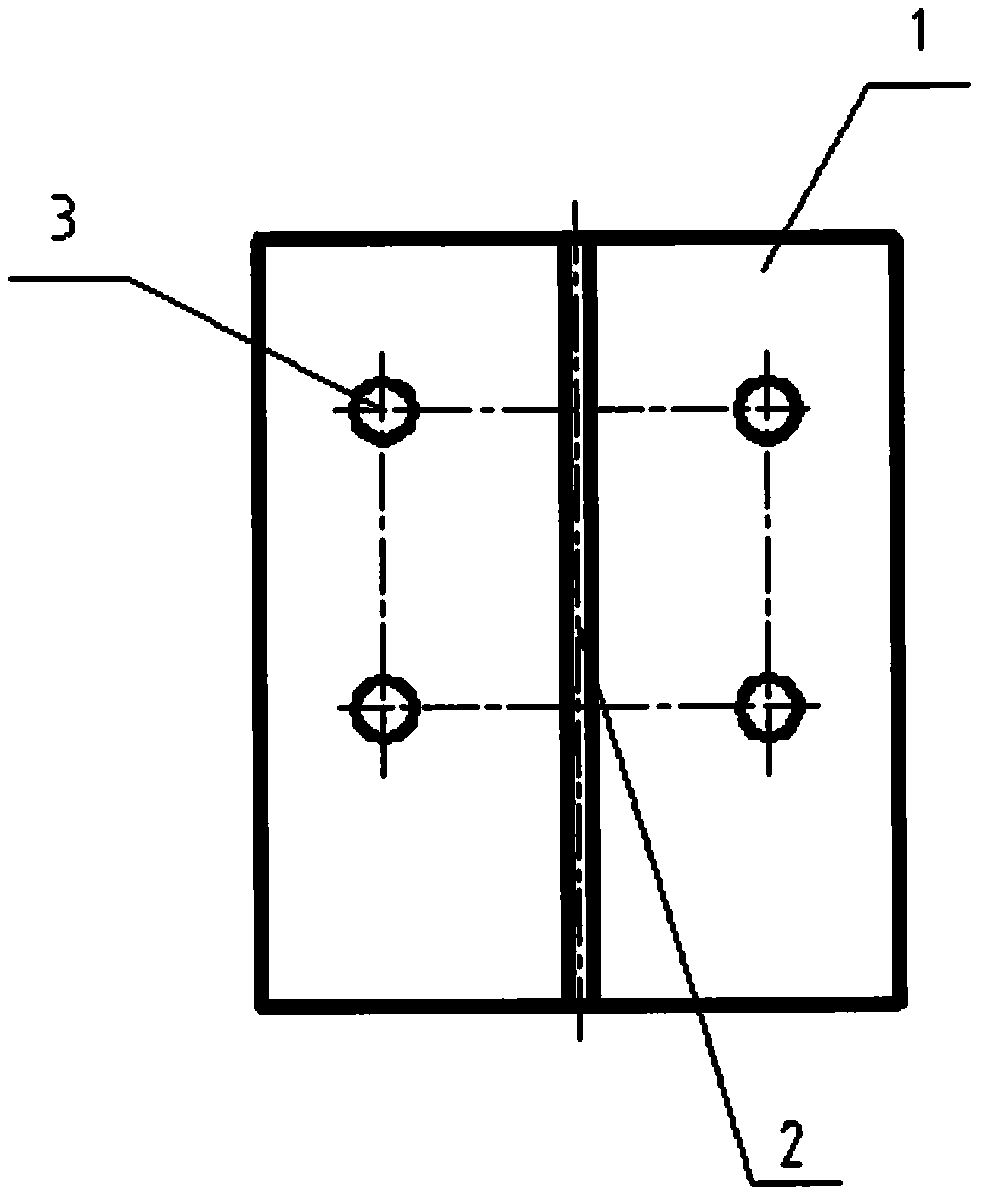

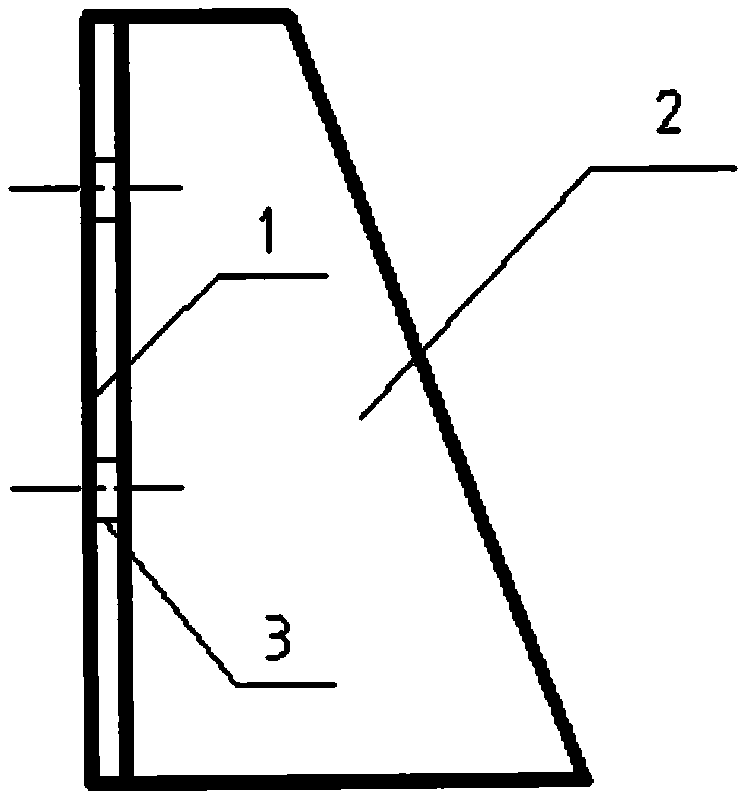

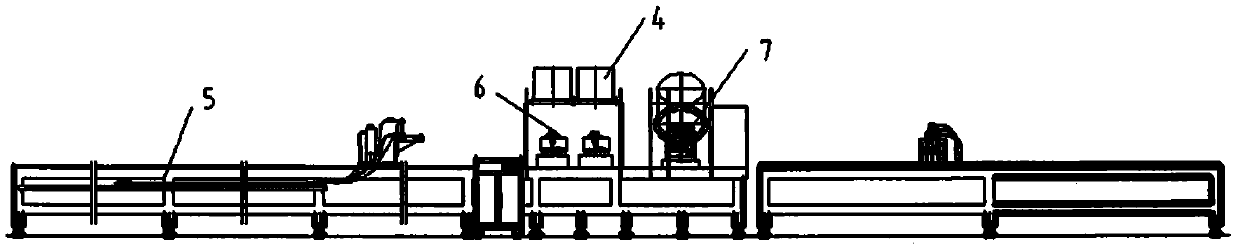

[0022] A continuous automatic manufacturing process of T-shaped steel purlin supporting plate is characterized in that it comprises the following process steps:

[0023] Step 1: Cut the coiled plate according to the required size through the slitting and leveling unit and straighten two straight steel strips, which are respectively used as the connecting plate 1 and the supporting plate 2; specifically, firstly, the raw material coiled plate Longitudinal slitting is carried out through the vertical and horizontal combined shearing and leveling unit. The slitting is to use the up and down staggered disc knife to make continuous circular motion according to the required width, and cut the coiled plate to determine the dimensional consistency of the width direction of the slab. The divided slats are leveled on-line by the leveling machine, cut to length and cut horizontally, and made into strip-shaped steel plates with the required width for the connecting plate and supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com