A control system and control method for a concrete bridge deck prefabricated slab production line

A control system and concrete technology, applied in the field of bridge pouring, can solve the problems of unstable pouring effect and environmental changes, and achieve the effects of easy emergency disposal, strong adaptability and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

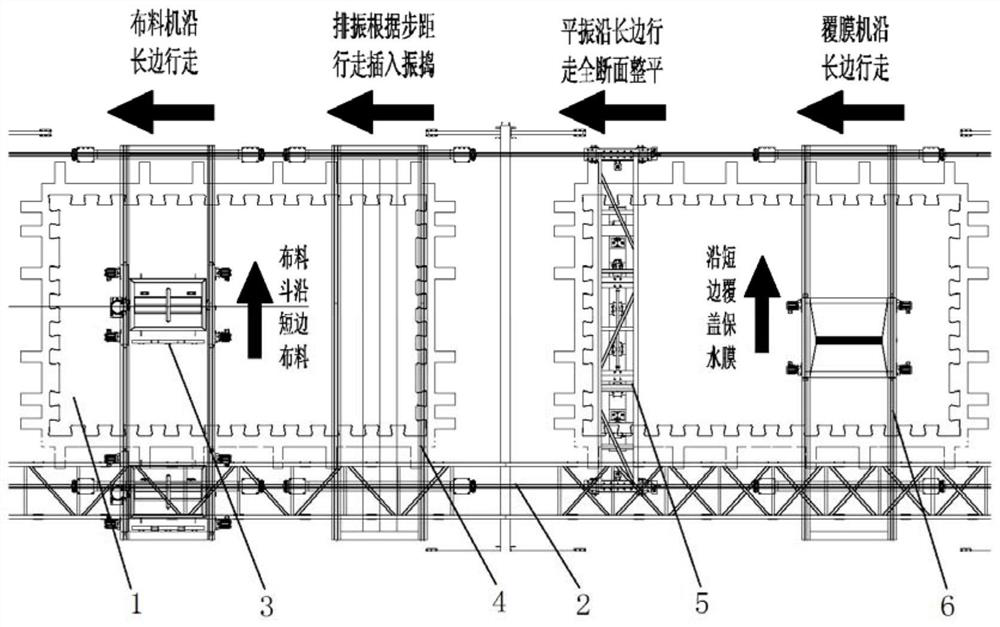

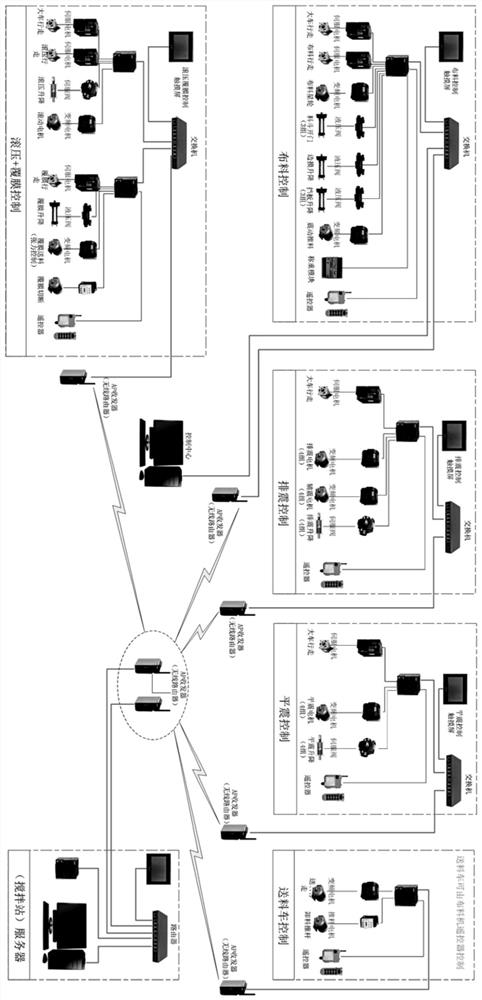

[0023] Such as Figure 1-2 As shown, the present invention provides a control system for the production line of prefabricated slabs of concrete bridge slabs, to control the production line of bridge slabs poured with coarse aggregate active powder concrete. The production line includes a track 2, a distributing machine 3, an array vibrating machine 4, a flat vibrating leveling machine 5, a rolling and laminating machine and a control system, and the control system controls the distributing machine 3 and the array vibrating machine respectively. machine 4, the flat plate vibrating leveling machine 5 and the rolling and laminating machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com