Humidifying device for concrete standard curing and curing system thereof

A standard curing and humidifying device technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve problems such as unfavorable environment and cleanliness, surface damage of test pieces, water accumulation on the floor of the curing room, etc., to achieve land saving, excellent fogging speed, The effect of increasing the water surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

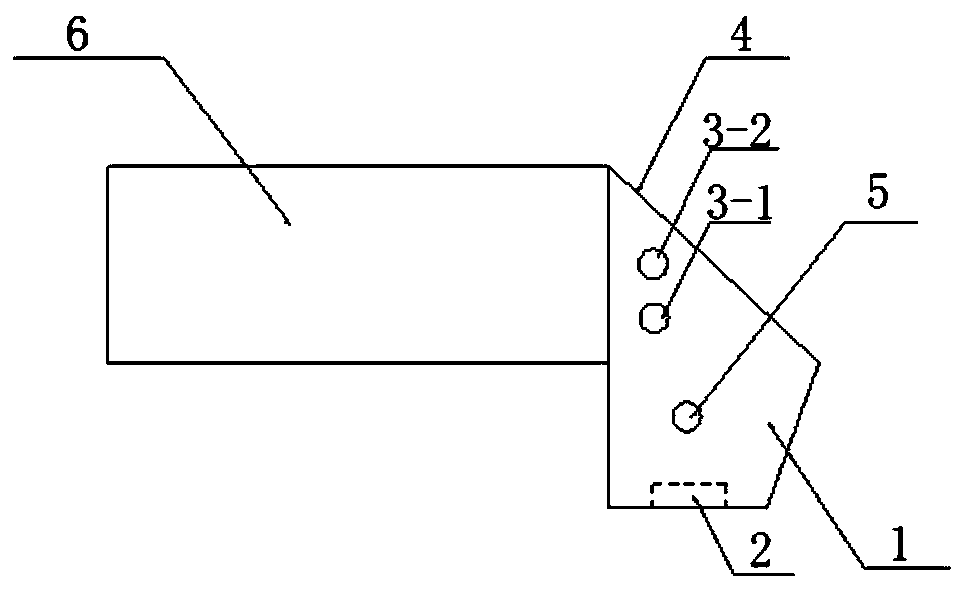

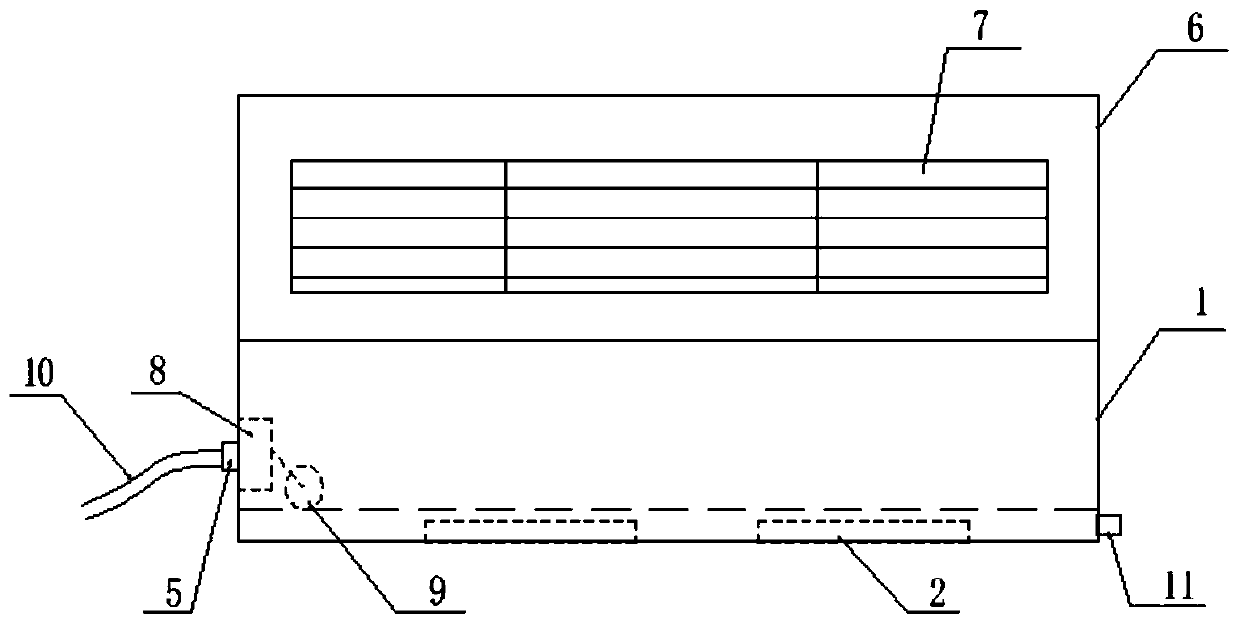

[0028] Such as figure 1 , figure 2 As shown, a humidifying device for concrete standard maintenance of the present invention includes an air conditioner 6, a water tank 1 and an ultrasonic generator 2. The air conditioner 6 is wall-mounted and installed on the wall of the curing room, and the air outlet 7 can be placed under it. The water tank 1 is disassembled and installed, and the air outlet 7 is facing the mist outlet 4 of the water tank 1 . Specifically, such as figure 2 As shown, the left and right side walls of the water tank 1 are correspondingly installed on the left and right sides of the air conditioner 6, and the side walls of the water tank 1 parallel to the air outlet 7 of the air conditioner are lower than the left and right side walls of the water tank 1, thereby facilitating the installation of the water tank 1 on the one hand. Installation and pipeline setting; on the other hand, the air-conditioning outlet 7 can be directly facing the inside of the water...

Embodiment 2

[0032] A kind of humidifying device for concrete standard maintenance of the present embodiment, its main structure is basically the same as that of Embodiment 1, and its main difference is: the side where the water tank 1 and the air conditioner 6 are located (such as figure 2 As shown, that is, the left and right sides of the air conditioner 6) are respectively provided with a water inlet 5 and a water outlet 11 on two vertical opposite side walls, the water inlet 5 is connected with the water inlet pipe 10, and the water inlet pipe is a transparent plastic hose and is connected to the outside The water supply device (curing room faucet) is connected, and the water inlet 5 is provided with a float control valve 8 and a float 9. One end of the floating ball 9 is connected with the connecting rod on the floating ball control valve 8, and the connecting rod passes through the water inlet 5 and is connected with the valve. The other end is a free end, which can float on the liq...

Embodiment 3

[0035] A standard concrete curing system in this embodiment includes a curing room and the humidifying device in Implementation 2. Wherein, the wall body of the curing room can be made of a material with better thermal insulation performance, which is beneficial to reduce the temperature fluctuation of the curing room, and thus can effectively ensure the curing effect on the concrete specimen. At the same time, the location and number of humidification devices installed above can be reasonably configured according to the actual size of the curing room, so that the curing of the concrete specimen can achieve better results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com