Method for preparing environment-friendly plasticizer DOTP from waste white mud

An environmentally friendly plasticizer and waste technology, applied in the field of preparing environmentally friendly plasticizer DOTP, can solve the problems of white mud occupying land resources, surface weathering and dust pollution, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

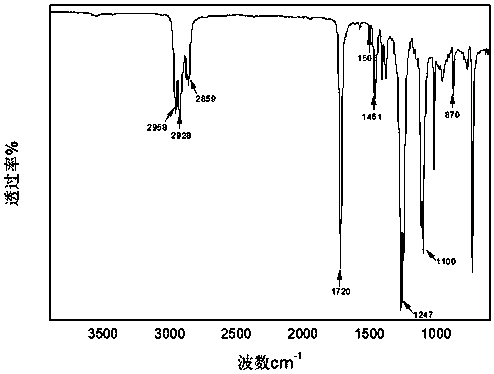

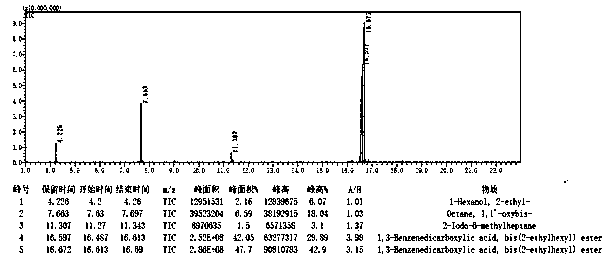

Method used

Image

Examples

Embodiment 1

[0024] (1) Esterification reaction: Add 24.92g of dried acid-treated waste lime mud and 68.37g of 2-ethylhexanol into a three-necked flask, wherein the molar ratio of white mud: 2-ethylhexanol is 1 : 3.5; continue to add catalyst tetrabutyl titanate 0.93g; heat the electric heating mantle to 220°C, measure the acid value of the system after constant temperature reaction for 8 hours, if the acid value is less than 1mg KOH / g, stop the reaction, and pump under -0.1MPa after cooling Filter for 3 hours; if it is greater than 1mg KOH / g, continue the esterification reaction;

[0025] (2) Neutralizing water washing: use 5% Na under the condition of heating in a water bath at 70°C 2 CO 3 The solution neutralizes the above filtrate until the acid value is less than 0.1mgKOH / g, washes it with water several times, and after standing still for 24 hours, take the upper layer solution;

[0026] (3) Dealcoholization: the upper layer solution, that is, the ester layer, was placed in a round-...

Embodiment 2

[0031] (1) Esterification reaction: add dried acid-treated lime mud, 2-ethylhexanol and tetrabutyl titanate into a three-necked flask, and the molar ratio of waste lime mud: 2-ethylhexanol is 1:6; the amount of catalyst added is 3% of the total mass of waste lime mud and 2-ethylhexanol; the electric heating mantle is heated to 260°C, and the acid value of the system is measured after 7 hours of constant temperature reaction. If the acid value is less than 1mg KOH / g , stop the reaction, suction filter at -0.1MPa after cooling; if it is greater than 1mg KOH / g, continue the esterification reaction;

[0032] (2) Neutralizing water washing: use 5% Na under the condition of heating in a water bath at 90°C 2 CO 3 The solution neutralizes the above filtrate until the acid value is less than 0.1mgKOH / g, washes it with water several times, and after standing still for 24 hours, take the upper layer solution;

[0033] (3) Dealcoholization: put the upper solution, that is, the ester lay...

Embodiment 3

[0036] (1) Esterification reaction: add dried acid-treated lime mud, 2-ethylhexanol and tetrabutyl titanate into a three-necked flask, and the molar ratio of waste lime mud: 2-ethylhexanol is 1:2; the amount of catalyst added is 1% of the total mass of waste lime mud and 2-ethylhexanol; the electric heating mantle is heated to 200°C, and the acid value of the system is measured after constant temperature reaction for 8 hours. If the acid value is less than 1mg KOH / g , stop the reaction, suction filter at -0.1MPa after cooling; if it is greater than 1mg KOH / g, continue the esterification reaction;

[0037] (2) Neutralizing water washing: use 5% Na under the condition of heating in a water bath at 60°C 2 CO 3 The solution neutralizes the above-mentioned filtrate; after the acid value is less than 0.1mgKOH / g, it is washed with water several times, and after standing still for 24 hours, the upper layer solution is taken;

[0038] (3) Dealcoholization: put the upper solution, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com